TLV Euro Engineering has launched QuickStation™ QS10, a compact, reliable steam trap station for use with TLV QuickTrap® to allow for condensate drainage from steam mains, tracers and light processes, which is suitable for use in pharmaceutical, food and beverage applications or where ease of steam trap installation and maintenance is critical.

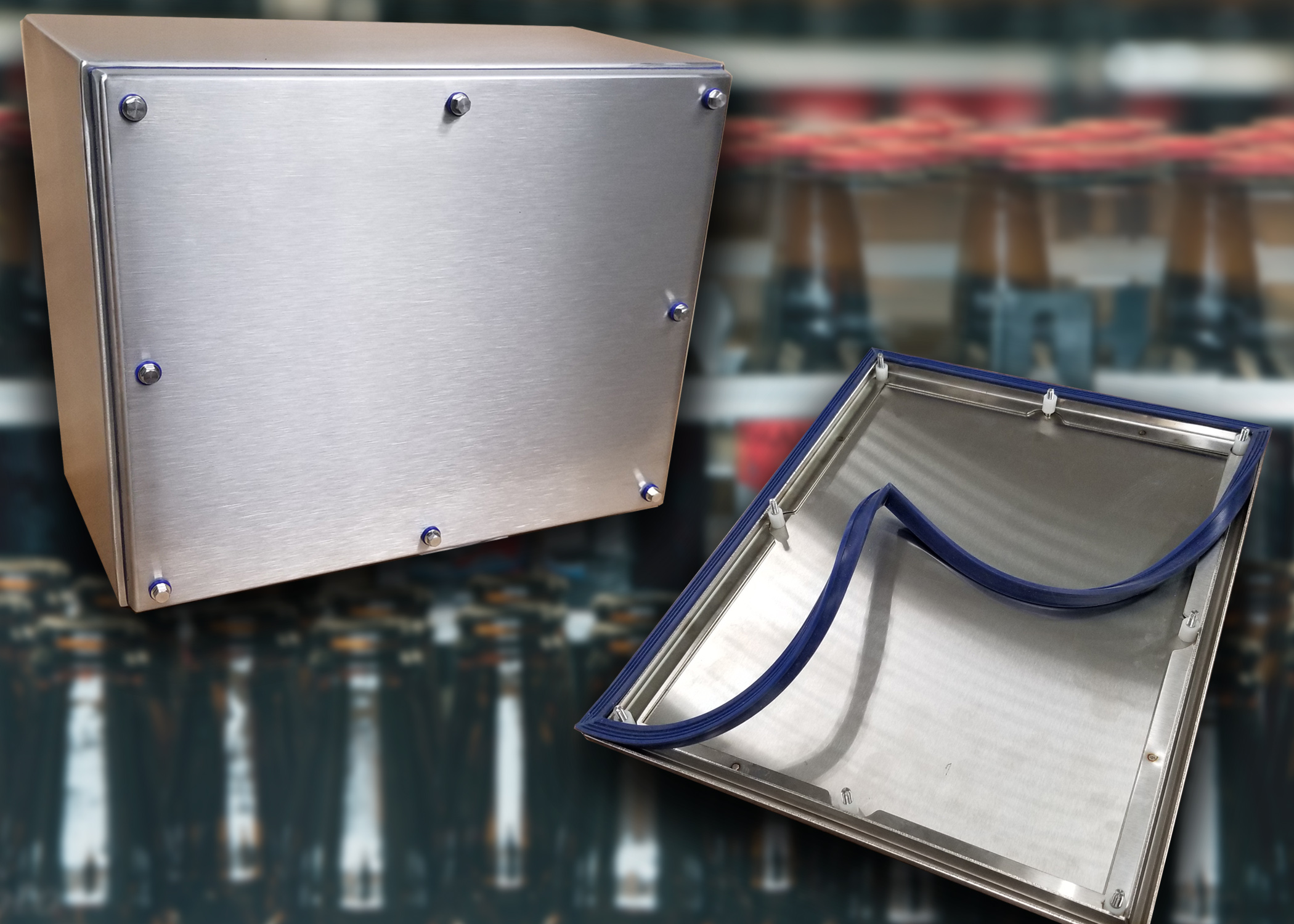

The QuickStation QS10’s compact, all-in-one design and reliable operation enables simple, inline trap installation in either the horizontal or vertical plane in minutes. It is constructed from stainless-steel for durability and corrosion resistance and is suitable for applications with maximum operating temperature of 185ºC and maximum operating pressure of 10 barg.

The four models in the QS10 range are offered with multiple piping arrangements and either single or double upstream/downstream isolation valves. The double isolation, along with optional BD2 blowdown valve, allows operators to blow out condensate/steam to prove safe isolation and allow for a safe replacement. An integrated strainer helps to prevent equipment damage or production issues due to entrained material, and an integral check valve prevents backflow.

TLV Euro Engineering also offers a range of precision-engineered QuickTrap models compatible with QuickStation for numerous applications, including its renowned Free Float® traps to minimise steam loss and save energy, and balanced pressure thermostatic and thermodynamic models for specific applications.

By making trap installation, replacement, and maintenance simple, costly steam trap problems can be rectified quickly, preventing energy loss, preventing system damage and improving energy efficiency.

For further information on the QuickStation QS10 and other steam solutions, call TLV Euro Engineering on +44 (0)1242 227223, email This email address is being protected from spambots. You need JavaScript enabled to view it. or visit www.tlv.co.uk.