Following an extensive upgrade of its reception tank and digester mixing system, Eco Verde Energy (EVE) has put a once troublesome Anaerobic Digestion (AD)+ plant firmly back on track with encouraging new biogas yields.

At Holton* in Suffolk, England, which receives around 65% of its feedstock from the adjacent Bernard Matthews poultry facility, the AD plant, under a series of different operators, had seen biogas production drop significantly, and eventually to a complete halt for a much-needed overhaul.

Initially, the primary digester (2700m3) was drained down, discovering, as expected, faults with the mixers, but also a broken stanchion. Later, further inspections revealed that there was damage to the roof of the digester, so the decision was taken to postpone operations for a complete maintenance revamp.

“The mixers that were sold in as part of the biogas package were never going to last in the long-term,” said Eco Verde’s Site Manager at Holton, Kris Martin.

“It is hard to understand a design that doesn’t allow equipment to be looked after! The mixers couldn’t be lifted out of the tank for even the most basic of service tasks such as an oil change and cleaning the propellers.”

He added: “At one point, the site was being run remotely, but it has now benefitted from a complete review of operations. When we shut down for the maintenance overhaul, trying to get shipshape became more challenging, due to some suppliers not being able to assist; either unable to provide equipment quick enough for our needs, or did not seem to have a deep understanding of the industry. Either way, the essential assistance we required was not readily available. We couldn’t for example, get anyone to look at the feed-in module (which is a jacketed tank to provide heat) we have between the reception tank and the digesters. The previous chopping pump had failed because of the high temperatures, so again, it wasn’t specified properly. There can be a huge difference in supplying equipment in 304 stainless steel compared to 316. For a biogas process with food waste, compromising is only going to lead to problems. This has been the classic case of a package plant being sold on price rather than quality.”

Matters took a significant turn for the better though when Kris made contact with Landia, about whom he’d heard good reports.

‘Clearly wanted to try and understand how a solution could be found’

He continued: “They’re a pump and mixer company, and there are plenty of those,” he said, “but unlike some others, they actually listened and clearly wanted to try and understand how a solution could be found. As soon as they first came to the site, there was a good vibe. Linking up the mixing operation from the reception tank, through the feeding module, and then on to the digesters, and finally through to the pasteurisers, wasn’t going to be easy, but rather than just try and sell us equipment, Landia were keen to find a way to help make the Holton plant perform as it should.”

New submersible mixers (5.5kW) from Landia have been installed for the reception tank, which unlike the previous units, can be easily lifted up on a crimped rail system for inspection to remove any plastics and perform standard maintenance such as oil changes.

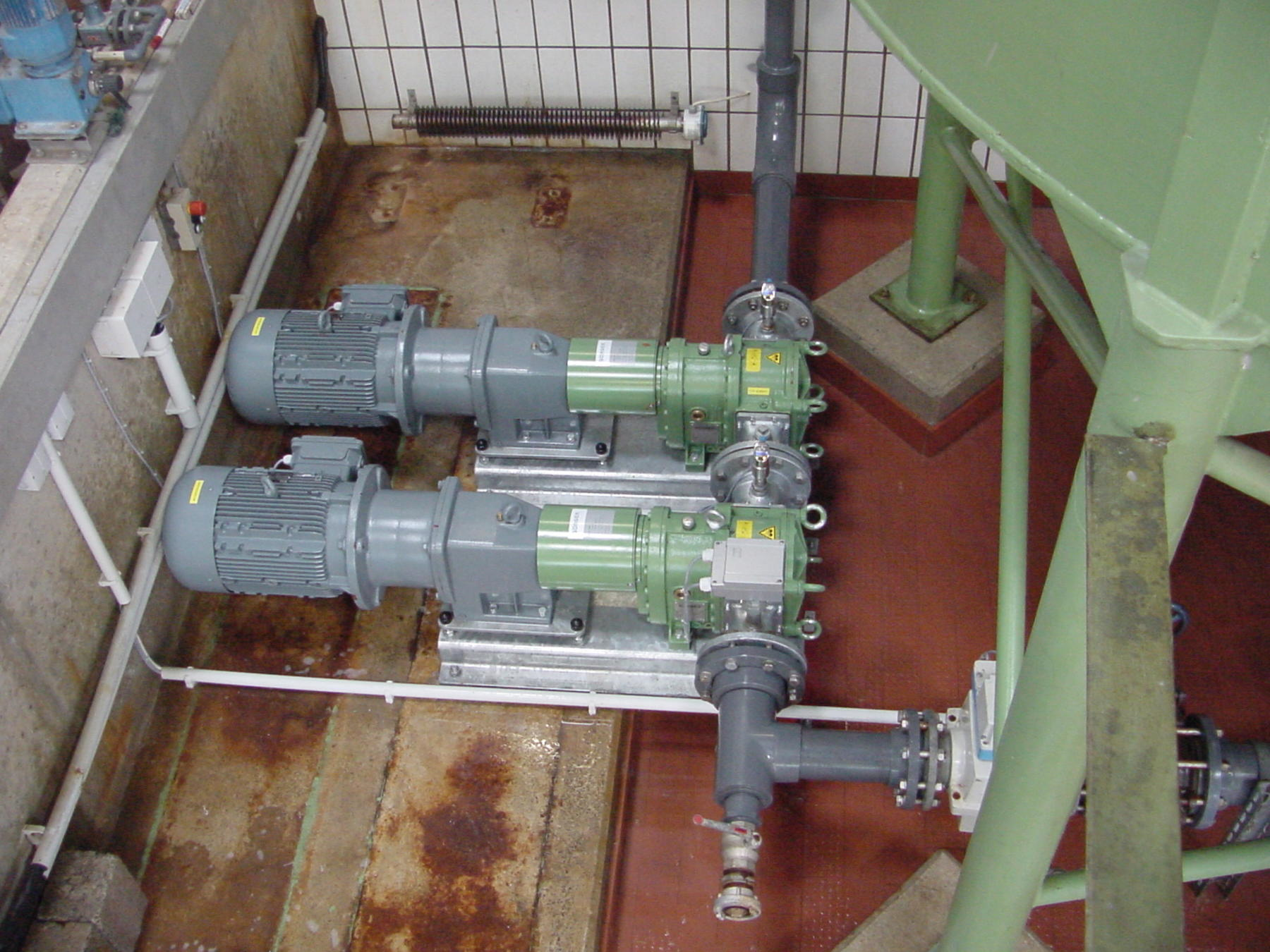

For the feeding module, which is batch-fed from the reception tank, a Landia Chopper Pump (invented by the company in 1950) has replaced the failed unit. The unique external knife system (combined with the addition of a new shredder propeller) ensures that particles are continuously reduced in size, and that solids cannot enter the pump’s casing.

The primary digester was first upgraded to replace the failed units with Landia mixers. By utilising a pre-existing hatch system that provides easy access, these new 18.5kW mixers were installed with minimal disruption to the biogas process, and can likewise be easily serviced without causing downtime.

The secondary digester is now served with a system that comprises the proven Landia chopper pump, fitted with venturi nozzles to provide truly comprehensive mixing. When the primary digester meets the right level, the feedstock is automatically transferred to the secondary digester. The simple, but highly effective combination of submersible mixers, chopper pumps, and the venturi nozzles work to constantly recirculate the mixture of liquid and gas, even though it only typically has to run in 10-minute intervals, rather than mixers at many plants that run flat-out 24/7.

At the end of the process, in order to meet the legal requirements of a feedstock that contains animal bi-products, there are now two (25m3) Landia pasteuisers, which heat the final effluent to the required temperature of 70 degrees centigrade. The pasteurisers are supplied as complete processing units (tank, chopper pump, and controls), to break down the food waste effluent and any remaining solids. Each tank from Landia is made with a double stainless-steel tank wall that acts as a heating jacket. From here, heat is transferred by circulating hot water, meaning that a heat exchanger is not always required. Post-pasteurisation, with the maximum possible amount of gas extracted, the final digestate from Holton makes a first-class, nutrient-rich fertiliser.

‘Nothing on this site is now off-the-shelf’

Kris Martin added: “The more Landia and I worked together, the more we had a focal point. Although they do provide some guide rails and pipework, it’s not their main business, but when looking at how we could transfer everything from the start of the process, right through to the pasteurisers, it made sense for Landia to include it as part of their service, rather than me having to bring in another supplier. They did a top-quality job in putting all the extensive pipework together. It’s very impressive and we’re all proud of it. Nothing on this site is now off-the-shelf. Paul Broadhurst (from Landia) and I have put this all together step-by-step. It’s not been easy, but we’ve worked through it with a very healthy rapport and that all-important common goal of wanting something to work and work well for the long-term. It’s a world away from the daily hassles that we had previously. Paul’s attitude to whatever we ask is ‘we’ll sort it out’, and I know he and Landia will, because they value us as a customer and care about the plant’s success.”

In addition to its primary feed (which is first treated by a DAF -Dissolved Air Flotation) piped in from the Bernard Matthews poultry facility’s treatment plant, EVE’s Holton site also receives effluent from the local Adnams brewery and distillery, plus various fats and oils from nearby food processing plants. This variety of intake then takes very careful managing to maintain a steady feed for the now, much loved biogas plant.

Kris Martin continued: “With the Landia submersible mixers at the front end, we’ve gradually developed a constant, homogenous feed, which provides excellent stability for the remainder of the process and our drive to maximise biogas yields. The consistency we have means happy bugs, because otherwise, too much of one intake at one time can cause foaming. That’s not an issue at this site any more.”

At 1.1MW, the new-look Holton biogas plant (which now has two CHP engines and additional gas storage), can provide most of Bernard Matthews' 1.4MW energy needs, with a grid connection in place for times if/when the poultry facility is on shutdown.

‘Low energy consumption

and maximum biogas yields’

Kris commented: “The investment here safeguards the future, with plans for a lagoon to be built and to have PAS 110. With Landia’s help, it means that we’ll be in good shape with low maintenance costs, low energy consumption and maximum biogas yields, which of course means profit – not to mention the fact that we do something great by making renewable energy from waste.

“Having to shutdown and clean out a couple of digesters creates downtime of almost three weeks; costing in the region of £150,000. We’re pleased of course to have now sorted out all the problems; turning everything around so that instead of having put out fires, we can finally be proactive and concentrate on making gas, rather than having to react to all the problems on site. The initial issues were made all the worse by having equipment that you couldn’t work on without having to shut the plant down! A design that effectively traps mixers inside the tank without access is ridiculous.

“We now have a proper maintenance schedule in place, and unlike in the past, no problems or delays in the availability and delivery of parts. If we order before lunchtime, Landia deliver the next day. During installation, there were also never any problems with the paperwork and permits from Landia; progress emails, and all the necessary RAMS (risk assessment and method statement) and proof of qualification were in place so that the work was seamless, with no delays. This differs significantly from others who simply aim to provide a product, without considering how it integrates into our process.

“Site managers can overcome all sorts of challenges, but aren’t necessarily engineers. You need calculations. You need experts to answer your questions to complete the jigsaw puzzle. No two plants are the same. It is reasonable to expect seamless support from the companies that provide equipment, but often, you find yourself navigating through various departments – from quotations to finance, engineers, and a loosely termed ‘support team.’ Having to repeatedly explain your requirements can be very frustrating and time-consuming. It is always easier to work with those who have been to a biogas plant, and who aren’t worried about getting their hands dirty. It’s been a long journey to get where we are, but we now have peace of mind with a plant that is performing very well and with fine-tuning, will get even better. It shows exactly what can be achieved with the right people, the right equipment, and a belief in our industry.”