Flowcrete UK's project management service offers the complete solution underfoot for the food and beverage sector – drawing on 30 years' experience in the flooring industry and its extensive network of approved flooring contractors.

Flowcrete UK's project management service offers the complete solution underfoot for the food and beverage sector – drawing on 30 years' experience in the flooring industry and its extensive network of approved flooring contractors.

Isocrete Project Management offers a single source route, extending from the initial project consultation process, through to warranty and aftercare.

Operating throughout the key stages of a project, the management process offers a bespoke service from initial consultation, product specification, product manufacture and logistics management, through to product installation from a trained Flowcrete approved contractor - and all backed by a comprehensive product and installation warranty.

Within the food and beverage sector, the process includes the installation of Isopol SBR polmer modified wearing screeded, hygienic seamless resin coating, integrated drainage, coving and hygienic wall covering.

The Christmas holiday shutdown period provides a window of opportunity to introduce a new floor finish, creating an inspired finish for processing and manufacturing centres to mark the start of the New Year - and aiding health and safety underfoot.

The Christmas holiday shutdown period provides a window of opportunity to introduce a new floor finish, creating an inspired finish for processing and manufacturing centres to mark the start of the New Year - and aiding health and safety underfoot. A prestigious new production facility at McVities in Glasgow has started out on a firm footing with the installation of a range of hygienic floor finishes from Flowcrete, including Flowfresh, which utilises the natural power of silver to deliver the level best in advanced protection. Lines 14 and 19 at the Tollcross-based plant have been developed to include the latest in food production technology.

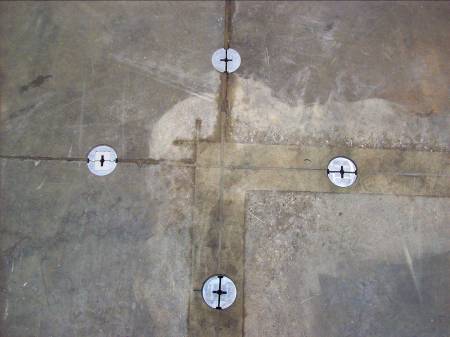

A prestigious new production facility at McVities in Glasgow has started out on a firm footing with the installation of a range of hygienic floor finishes from Flowcrete, including Flowfresh, which utilises the natural power of silver to deliver the level best in advanced protection. Lines 14 and 19 at the Tollcross-based plant have been developed to include the latest in food production technology. The CoGri Group has acquired exclusive European distribution rights for the patented SD7 Joint Saver, which will be marketed as the CoGri Joint Stabiliser and managed by CG Flooring Systems Ltd.

The CoGri Group has acquired exclusive European distribution rights for the patented SD7 Joint Saver, which will be marketed as the CoGri Joint Stabiliser and managed by CG Flooring Systems Ltd.

Concrete Grinding successfully completed a Fast -Track floor solution program for The Oxford University Press’s (OUP) new distribution centre in Kettering.

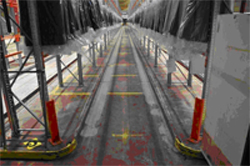

Concrete Grinding successfully completed a Fast -Track floor solution program for The Oxford University Press’s (OUP) new distribution centre in Kettering. Concrete Grinding Ltd returned to France to provide a floor grinding solution for an existing client, 3 Suisses. Working in partnership with the main contractor, Promadis, an extension to the existing VNA facility in Villeneuve d’Ascq near Lille, North of Paris required the floor to be ground to tolerance ready for racking installation.

Concrete Grinding Ltd returned to France to provide a floor grinding solution for an existing client, 3 Suisses. Working in partnership with the main contractor, Promadis, an extension to the existing VNA facility in Villeneuve d’Ascq near Lille, North of Paris required the floor to be ground to tolerance ready for racking installation.

CoGri Group has been involved in providing SuperFlat floors in Asia since 1992. To serve the rapidly developing Logistics Industry in Singapore, CoGri Asia Pacific Pte Ltd (CGAP) was formed in 1994.

CoGri Group has been involved in providing SuperFlat floors in Asia since 1992. To serve the rapidly developing Logistics Industry in Singapore, CoGri Asia Pacific Pte Ltd (CGAP) was formed in 1994.