Concrete Grinding Ltd returned to France to provide a floor grinding solution for an existing client, 3 Suisses. Working in partnership with the main contractor, Promadis, an extension to the existing VNA facility in Villeneuve d’Ascq near Lille, North of Paris required the floor to be ground to tolerance ready for racking installation.

Concrete Grinding Ltd returned to France to provide a floor grinding solution for an existing client, 3 Suisses. Working in partnership with the main contractor, Promadis, an extension to the existing VNA facility in Villeneuve d’Ascq near Lille, North of Paris required the floor to be ground to tolerance ready for racking installation.Concrete Grinding Ltd has previously worked for 3 Suisses in December 2008 through to January 2009 when they were first commissioned to provide Laser Grinding to two of the client’s DC near Lille, one of which was in Villeneuve d’Ascq. At that time the client had an aging MHE system in a large portion of their facility. However, after seeing how beneficial the Laser Grinding system can be, the client then modernised with an extension area, resulting in the revisit completed this year.

Using the Laser Grinder®, Concrete Grinding Ltd carried out 2 wheel tracks grinding to 13 aisles totalling 702 metres to meet with TR34 CAT 2 floor flatness specification. A further 197 metres were laser ground in the centre of the narrow aisle where joints in the floor were out of specification.

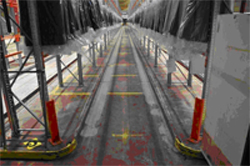

The VNA Fork Lift Trucks (FLT) are guided within the aisle by high profile guide rails. At the client request, the Laser Grinding was set up in such a way that the FLT wheels and the guide rails both sit into the ground paths. As the Laser Grinding preceded the racking installation, the alignment of the grinding was critical, particularly as the guide rails and front wheels of VNA truck were required to be located in the cut path. By using a 380mm diameter cutting blade, designing tight tolerances and also maintaining straight cutting lines, this was successfully achieved with minimum clearance either side of the guide rails and the VNA front wheels. This is the best approach when considering ground clearances of VNA truck’s out-rigger wheels.

After the designated aisles had been ground, the new racking was fitted and stocked. Concrete Grinding Ltd then proceeded with the remaining aisles, proving that the Laser Grinder® system is clean enough to work alongside fully stocked racks and does not affect the day to day warehouse operation – a factor that is vital for a busy client.

3 Suisses International has operations in France, Belgium, Germany and China. Through its catalogue and via its website, 3 Suisses offers up-to-the-minute fashions for men, women, children and a selection of household and leisure products. Through its catalogue and via its website, 3 Suisses offers up-to-the-minute fashions for men, women and children, and a selection of household and leisure products.

Concrete Grinding Ltd are specialists in the upgrading of aisles in new and existing VNA/narrow aisle warehouse units. Key products are:

• Laser Guided Grinding up to ‘DM1 / Superflat’ Standards for VNA/narrow aisle environments using the LASER GRINDER ®

• Bespoke internal repairs/upgrades tailored to the individual clients’ needs.

The Laser Grinder® enables aisles on new and existing floors to be upgraded to the flatness standards required to operate VNA forklift trucks safely and at their optimum efficiency. The Laser Grinder® is designed to grind either the individual wheel tracks of a forklift truck or the whole aisle width, for complete flexibility. The wet, vacuum-enclosed grinding process is free from airborne dust and clean enough to work alongside fully stocked racks - even in food and pharmaceutical storage facilities.

Concrete Grinding Ltd are part of the CoGri Group of companies, a consortium of international industrial floor solution specialists with over 20 years global experience in the Design, Construction, Upgrading and Repair of Industrial Concrete floors.

For more information, please visit www.concrete-grinding.com

Concrete Grinding Ltd

Tel: + 44 (0) 1484 600080

Fax: +44 (0) 1484 600095

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.