More Editorial

Directory

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE

Test Products International (TPI), is a leading, global, high-tech test and measurement company providing Affordable Solutions to Industries Predictive and Proactive Maintenance schedules. With a range of Vibration & Bearing Condition Analysers starting, from under £500, through Bluetooth Connected Analysers c/w Subscription FREE PC Trending Software, Fixed System Monitors for 24/7 Critical Plant Operations to ATEX approved Intrinsically Safe Models,which also include Single & Two Plane Balancing, TPI has a solution for all professional engineers working in commercial and industrial applications, no matter the size of the business, and all backed by a lifetime of support.

Contact Details Tel : 01293 530196 Fax : Email : Cbmsales@tpieurope.com Web : https://tpieurope.com

YOUR PARTNER IN ULTRASOUND

Technology. Training. Tools. Resources. UE Systems is the world leader in providing ultrasonic instruments & training solutions for predictive maintenance, reliability, condition monitoring and energy saving programs (https://www.uesystems.com/applications/).

We assist companies worldwide implementing ultrasound technology in their predictive maintenance & reliability best practices. For this, UE Systems provides the right inspection instruments (https://www.uesystems.com/products/), the right training (https://www.uesystems.com/training/training-overview/), license-free software (https://www.uesystems.com/learning-center/software-download/) and continuous support. By guiding companies in establishing and maturing an ultrasound inspection program, we assist them in achieving:

info@uesystems.com (mailto:info@uesystems.com)

North America: +1-914.592.1220

Europe: +31-546 725 125

India & Middle East: +91 9491073736

Asia: +852 2919 6886

Central & South America: +1-914 592 12 20 ext. 635

Contact Details Tel : 0019145921220 Fax : Email : Info@uesystems.com Web : https://uesystems.comSPM Instrument is a global leader in condition monitoring technology. We have supplied the world’s industries with high-performance condition monitoring solutions for fifty years, and we are passionate about what we do. Our entire focus is on developing world-class products for world-class reliability and maintenance – that sets us apart from other suppliers.

As a full-range supplier, we exclusively develop and market all the technology to measure, analyze, and present condition data from complex machinery. The power of our innovations enables our customers to tap into the potential of the world’s most efficient condition monitoring solutions.

In addition to advanced measurement technologies, our extensive product line covers everything from transducers, transmitters, and cabling to power-packed online and portable instrumentation and software, as well as methods and products for corrective maintenance, such as laser shaft alignment and balancing.

Our leading-edge, intelligent condition monitoring solutions make an excellent foundation for a proactive maintenance strategy, integrated into normal maintenance activities, and effectively providing an overall picture of the status of critical assets. Immediate and evaluated condition information is presented as green-yellow-red condition codes for instant and easy recognition of trouble spots.

We are the inventors of the ultra-efficient HD condition monitoring technologies. Providing unmatched forewarning times, they detect fault conditions well in time to plan maintenance and repairs for minimal interruption of the production process. Whether complex or straightforward, HD technologies have the power to address and resolve your reliability issues.

Our training center SPM Academy offers standardized courses and customized training for all levels of staff involved in condition monitoring, enabling them to be fully proficient and continuously update their knowledge of our products and technologies. We are an accredited Mobius Institute Training Partner, offering ISO CAT I - III vibration analysis training with certification, as well as SPM certified Condition Monitoring Analyst courses.

Our head office, including the R&D department, production facility, and training center SPM Academy, is located in Strängnäs, Sweden. The SPM Group is made up of more than two-hundred devoted professionals, eighty of whom are based in Sweden. Our highly trained global network of sales and service representatives – covering more than fifty countries – is here to support your maintenance department and help you get the most out of your condition monitoring program.

Contact us today – we look forward to hearing from you!

Contact Details Tel : 01706 835 331 Fax : Email : Web : https://spminstrument.co.ukAIP – Added Value Programme from bearing manufacturer NSK

Products and solutions provided by NSK can be found wherever things move. In addition to nearly all types of rolling bearing, the company’s portfolio includes housed bearings, linear motion technologies, wheel bearing units, transmission and engine bearings, and steering systems.

NSK not only offers the right products, but a comprehensive service provision to improve efficiency and competitiveness. AIP services are based on best practice and can be easily applied to a multitude of applications and processes. NSK experts advise companies on measures which can be deduced from the analysis results and provide support during implementation. By improving their machine reliability, technical knowledge and overall profitability, NSK helps its customers to reduce total cost of ownership.

EEMUA was founded in 1949 by major industrial players, with a vision of working together to establish standards in areas such as equipment and materials selection and specification, and engineering plant construction, and so drive good practice wider into industry.

EEMUA membership now spans many sectors including companies that manage process and power plants, utilities, offshore platforms, storage terminals and other industrial facilities throughout the world. The Association's technical activities cover the full scope of industrial asset management as an internationally recognised source of expertise and information for the engineering industry.

EEMUA plays a pivotal role in ensuring members’ physical assets and user requirements are in the best shape to contribute significantly to their companies. As a result, EEMUA focusses its efforts on the most critical issues.

EEMUA's aims meet a wide range of needs for the owners and operators of industrial assets across a range of sectors. From helping ensure a competent workforce to influencing standards and regulations abroad, the association focuses closely on maximising value for members.

Member companies own or operate many upper-tier COMAH (Control of Major Accident Hazards) and/or SEVESO establishments. Through knowledge sharing, EEMUA helps its members meet legal compliance requirements and challenge unreasonable expectations.

Contact Details Tel : Fax : Email : sales@eemua.org Web : https://eemua.org/

Welcome to our web site of courses for those tasked with the challenge of improving manufacturing performance.

DAK courses are designed to support the transfer of new ideas back to the workplace using practical workplace learning projects. Workplace learning projects provide immediate feedback which helps to surface barriers (real and imagined) overcome problems, refine ideas and progress them further.

Each course content includes activities to develop personal 90 day action plans to apply this “workplace learning” approach so that those impacted by the change have the opportunity to understand the benefits first hand, reflect on the changes needed and learn how to adopt the new approach into their work routines.

A typical workplace learning project passes through 3 measurable quality milestones:

Our mission is to disseminate practical information on evaluating the behaviour and condition of machinery without commercial interest.

The Institute offers a variety of programs, including education, training, certification, and opportunities for technical knowledge exchange. Our members share information, procedures, and cutting-edge data through formal training, networking, meetings, and publications. If you would like to join our network of esteemed colleagues, improve your skills, and expand your education in the study of machine vibration, contact us directly, and get started as a member.

Established in 1914, MSA Safety Incorporated is the global leader in the development, manufacture and supply of safety products that protect people and facility infrastructures. Many MSA products integrate a combination of electronics, mechanical systems and advanced materials to protect users against hazardous or life-threatening situations. The company's comprehensive product line is used by workers around the world in a broad range of markets, including the oil, gas and petrochemical industry, the fire service, the construction industry, mining and the military. MSA’s core products include self-contained breathing apparatus, fixed gas and flame detection systems, portable gas detection instruments, industrial head protection products, fire and rescue helmets, and fall protection devices.

Contact Details Tel : 01380 732700 Fax : Email : Info.gb@msasafety.com Web : https://gb.msasafety.com/

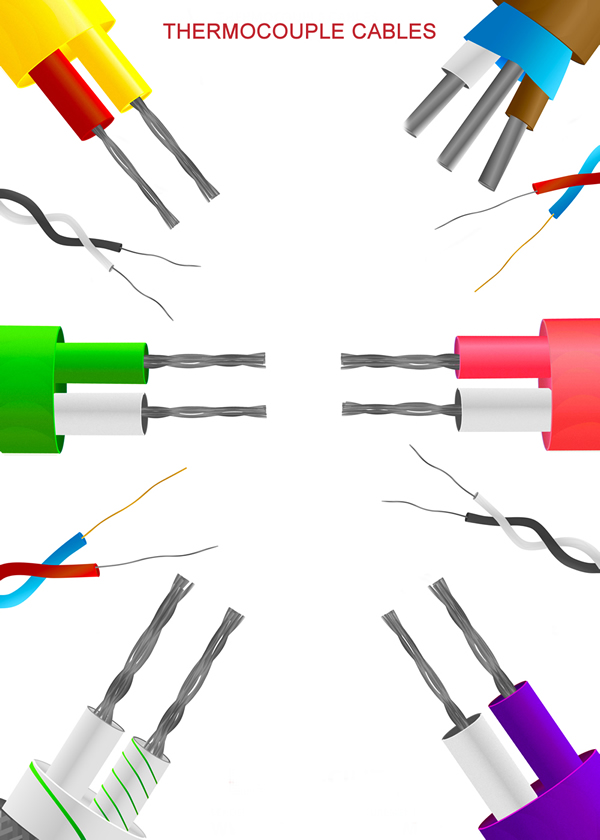

Labfacility are the UK’s leading manufacturer of Temperature Sensors, Thermocouple Connectors and associated Temperature Instrumentation and stockists of Thermocouple Cables.

The Company has been trading since 1971 and is ISO 9001 accredited. We have two UK sites – West Sussex and South Yorkshire and export to over 85 countries, Shipments are made to world-wide destinations on a daily basis.

In addition to the stocked items, Labfacility also offers bespoke Temperature Sensors. We are specialists in the design and manufacture of custom-built temperature sensors at our 18,000 square foot Yorkshire plant located in Dinnington. We also offer a wide range of components and fittings for sensor installation.

Quality and Service are key elements in the continued growth of Labfacility; technical support for both sensing and instrumentation is always freely available from our experienced technical sales teams.

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE