More Editorial

Directory

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE

Faraday Predictive - Overview

Faraday Predictive Ltd was set up in 2017 to help asset owners and operators become more efficient, through the adoption of optimised maintenance strategies, particularly Condition Based Maintenance, enabled by Model-Based Voltage and Current (MBVI) Condition Monitoring Systems.

Although Faraday Predictive was only set up in 2017, we bring more than a decade of experience with MBVI systems, and several decades of experience helping organisations improve the performance of their Maintenance and Operations activities.

Based in Cambridge, we build on the world-leading capabilities of Cambridge University departments including Mathematics, Computer Science and Engineering, allowing us to develop leading-edge solutions from the ground up. We have also had superb support from Mathematicians and Scientists from a number of other leading universities

We combine this academic expertise with deep practical experience of the worlds of maintenance and asset management, of traditional Vibration-based Condition Monitoring technologies, and of education, training and consultancy support to deliver real improvements in many different industry sectors. We have real experiences of implementing RCM, TPM, CMMS/EAMS, and a variety of other maintenance improvement initiatives.

We have used this experience to define and develop the Faraday Predictive Condition Monitoring Systems, to make sure they are easy to use, easy to install, and that they provide easy to understand, actionable advice, that explains why the system has diagnosed a particular problem, the likely effect of that problem, and the recommended course of action. In short, they are designed by engineers like you for engineers like you.

Whether you just want a quick assessment of the condition of one or two machines, or are looking to implement a comprehensive Condition-Based Maintenance strategy, we are here to help you – through the supply of world-leading technological solutions, education and training, or consultancy advice.

BEMAS is a not for profit organisation in the field of maintenance and asset management. We help asset intensive organisations in Belgium and Europe on the road to world class maintenance and management of technical equipment and infrastructure.

Contact Details Tel : Fax : Email : info@bemas.org Web : https://bemas.orgYOUR PARTNER IN ULTRASOUND

Technology. Training. Tools. Resources. UE Systems is the world leader in providing ultrasound instruments & training solutions for predictive maintenance, reliability, condition monitoring and energy saving programs. We assist companies worldwide implementing ultrasound technology in their maintenance & reliability best practices, by providing the right inspection instruments, the right training, license-free software and continuous support. By guiding companies in establishing and maturing an ultrasound inspection program, we assist them in achieving:

• Significant energy savings by finding compressed air leaks and faulty stream traps & reporting the savings opportunity

• Downtime reduction by monitoring the condition of bearings, preventing lubrication issues & identifying bearing failures at a very early stage

• Improvements in safety procedures by using ultrasound for discharge detection during electrical inspections, at a safe distance

IFS Ultimo EAM software

With IFS Ultimo Enterprise Asset Management (EAM) software, you gain a better grip over your assets, realize higher uptime, control costs, and create a safe and healthy working environment. IFS Ultimo is well known for its rapid deployment, ease of use, seamless integrations, and unparalleled time to value. IFS Ultimo gives manufacturing, logistics, and healthcare organizations, a flexible solution for all your asset maintenance and health & safety needs.

About IFS

IFS develops and delivers cloud enterprise software for companies around the world who manufacture and distribute goods, build and maintain assets, and manage service-focused operations. Within our single platform, our industry specific products are innately connected to a single data model and use embedded digital innovation so that our customers can be their best when it really matters to their customers—at the Moment of Service™️. The industry expertise of our people and of our growing ecosystem, together with a commitment to deliver value at every single step, has made IFS a recognized leader and the most recommended supplier in our sector. Our team of 5,500 employees every day live our values of agility, trustworthiness and collaboration in how we support our 10,000+ customers. Learn more about how our enterprise software solutions can help your business today at ifs.com.

|

Water Jetting Association The Water Jetting Association (WJA) is a UK-based membership organisation for contractors, manufacturers, and equipment hire specialists operating across all industrial sectors, including petrochemicals, heavy engineering and construction. It is committed to the highest possible safety and technical standards for water jetting, including ultra-high-pressure water jetting, high pressure water jetting, pressure washing, and sewer cleaning. The WJA has two Codes of Practice: the Blue Code for high pressure and ultra-high pressure water jetting; and the Red Code for the safe use of water jetting in drains and sewers. Both codes of practice, developed with the assistance of industry-stakeholders and the UK’s Health and Safety Executive, are recognised as setting industry standards in the UK and internationally. The WJA is the UK’s largest provider of water jetting training. Its City & Guilds accredited courses are delivered by registered training providers and approved instructors in the UK and internationally.

Contact Details Tel : (0) 20 8320 1090 Fax : Email : info@waterjetting.org.uk Web : https://waterjetting.org.ukBabcock Wanson is a major international provider of industrial process heating equipment and solutions with a pedigree dating back over 100 years. We have operating companies in eight countries in and around Europe, including two manufacturing sites, and a world-wide network of partners.

A key factor in our success stems from our ability to offer multiple, customised solutions to meet a customer’s needs. Rather than single solution based, we offer customers genuine choice, including a wide range of Thermal Fluid Heaters, Coil Steam Generators and Fire Tube Boilers; we provide the solution best suited to your needs, rather than a solution that fits our product range.

All products supplied by Babcock Wanson are fully supported, including tailored service and maintenance contracts.

In addition to a range of quality engineered products, Babcock Wanson also provides turnkey solutions. We have the engineering expertise and experience to customise our products and system designs to develop innovative solutions.

Contact Details Tel : (0) 20 8953 7111 Fax : Email : info@babcock-wanson.com Web : http://babcock-wanson.comRapid Energy designs, specifies and builds its own industrial HVAC equipment for short and long term hire. Operating nationwide, we provide a fast 24/7/365 service, capable of arriving on-site at a client's facility within hours. Rapid Energy can also provide client's with disaster recovery plans, consisting of a detailed site survey and equipment/plant requirements, ready to be dispatched if needed. The senior management team has a vast amount of HVAC hire experience in the UK.

Our fleet of packaged boilers start at the 100kW capacity, rising to the largest boiler in our fleet, the 2000kW (2MW) packaged boiler. Our boilers are designed, specified and manufactured in house. Each boiler is equipped with industry respected components that comprise of Viessman boilers, Riello burners, Grundfos pumps and Priva BMS for remote monitoring and management. Our packaged boilers are available for hire in multiple fuel types: Gas, IHO and HVO.

Rittal leads the world in providing solutions for industrial enclosures, power distribution, enclosure climate control and IT infrastructure. Deployed across a variety of industrial and IT applications, including automation, food and bev, transport, power generation, IT and telecommunications.

Rittal supplies all the automation support required to make enclosure assembly quicker, easier, more accurate and more reproducible. When combined with Eplan solutions, this makes it possible to link all enclosure assembly steps to create a highly efficient and digitally seamless automated process.

Rittal and Eplan can supply all the necessary software tools, machinery and equipment. These include perfectly coordinated software solutions, system technology, machinery and services that deliver unique competitive advantages in panel building and switchgear manufacturing. Using the Industry 4.0 concept to manufacturing with value chain solutions which combine value-enhancing process steps in engineering, design, work preparation and production.

For over 30 years, Newson Gale has been leading the way in hazardous area static grounding control, serving industries where processes generating static electricity have the potential to ignite flammable or combustible atmospheres.

In many branches of industry, hazardous (explosive) atmospheres exist due to the presence of flammable liquid vapours, gases, dusts and fibres, making it vital to eliminate all potential ignition sources; static electricity being perhaps the most insidious of them all. Static electricity is generated by virtually all operations and processes involving movement. Fires and explosions can occur as a result of uncontrolled static discharge from plant, people and materials, commonly resulting in civilian injuries and fatalities, as well as significant financial losses in direct property damage and plant downtime.

To help control these risks, Newson Gale offers a wide range of static grounding and bonding equipment which is made to provide optimum safety in explosive atmospheres and other hazardous operating environments.

Empteezy is the home of quality engineered spill containment and spill control products. Our overriding aim is to help you comply with legislation and implement best practice in connection with your oil and chemical storage needs, spill response programmes (including spill kits, emergency safety shower and tank shower applications) and waste handling projects. With our products, tailored to meet the requirements of a variety of different working environments including industrial, commercial, military, marine and educational settings, we manufacture in excess of 70% of the products available in our portfolio in our own factories, making us well placed to provide you with expert advice on how our products can help you meet UK, EU and International standards relating to spill containment and spill control of most liquids. Empteezy is a ISO 9001, ISO 14001 and OHSAS 18001 accredited company.

Contact Details Tel : 01506 430 309 Fax : Email : advice@empteezy.co.uk Web : https://www.empteezy.co.uk/?utm_source=hes&utm_campaign=marketingThe management at DSC has a background steeped in the evaluation, design, manufacture and supply of equipment required for the storage of hazardous substances. Developed out of necessity to solve customer problems, identified in some of the most sophisticated Hazardous Risk Assessments. Working hand in hand with our customer base, we have been able to develop a very unique way of thinking "outside of the box" looking at hazards in many ways that our clients cannot see, simply because they are too close or too familiar with the situation.

We provide a range of training courses provided by our skilled and experienced trainers including; DSEAR training, Fire Training and Spill training.

We specialise in this very specific niche market field, which ensures you the customer, get the very best of our years of experience, in identifying the risk, designing the solution, implementing the required changes and doing it in a safe cost effective way, such that it does not impact on your business. To find out more about what services we offer please visit our website.

Contact Details Tel : 01952 947682 Fax : Email : sales@dsc-ltd.co.uk Web : https://dsc-ltd.co.ukDHD Cooling offers a full service capability to the manufacturing, HVAC, thermal power plant, industrial and chemical industries, offering a bespoke service tailored to your exact cooling tower system requirements.

We are specialists in technologies such as hybrid water conservation systems, dry and adiabatic cooling units, plate heat exchangers and cooling towers. Delivering turnkey engineering design, installation, refurbishment or maintenance upgrades – DHD will project manage and deliver a solution which increases efficiency and performance, whilst meeting your maintenance budget and minimising downtime.

DHD will provide full reporting for your cooling equipment, including thermal performance, endoscopic and condition reports, providing you with full transparency about the effectiveness of your systems. We will also evaluate and inspect dry, wet and hybrid options.

Our engineers will offer advice and recommendations on relevant cooling technology legislation such as HSG274 part 1, ACoP-L8 and Eurovent ensuring that industry standards are met and your business is fully compliant.

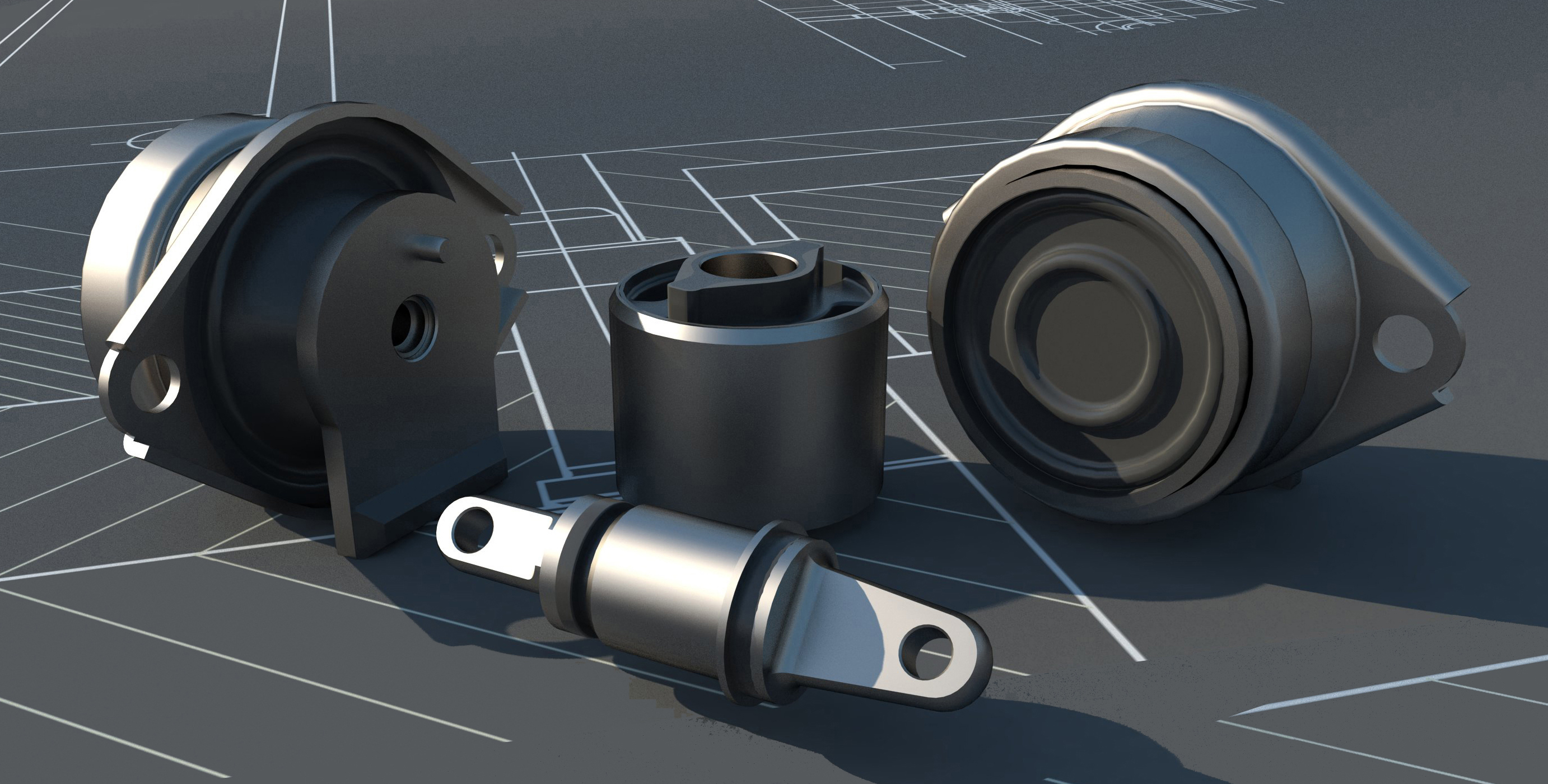

The Fibet Group was formed in 1952 – with an initial focus towards supporting the Automotive Industry in the development and manufacture of rubber to metal bonded parts and other elastomer components.

In the mid seventies, in addition to the existing range, FIBET started to develop and manufacture a large selection of rubber to metal bonded anti vibration and isolation components for other areas outside the automotive sector including earthmoving and off road machines, agricultural machinery, generators, railway industries, compressors, wind turbines to name a few.

Fibet have now been operating as an independent family run business for over 70 years, and are now renowned as one of the world leaders in the field of the mechanical application of elastomer.

This is supported with the largest range of anti vibration and isolation products available, as can be seen from our online catalogue.

Contact Details Tel : 01282 878200 Fax : Email : sales@fibet.co.uk Web : https://fibet.co.uk

Nightstick is a global brand of professional portable LED lighting products that meet or exceed industry standards. Our products are UL 913 certified for Class I DIV 1 (all gas atmosphere groups) and Class II DIV 1 (all dust atmosphere groups), many with a Zone 0 IIC equivalency rating for use in hazardous environments. Most additionally carry a Zone 0 IIC ATEX and IECEx certification with T3 & T4 temperature rating, making Nightstick a truly globally intrinsically safe lighting company. From penlights to area scene lights, Nightstick leads with over 50 safety rated LED lighting products.

Contact Details Tel : 0014693269400 Fax : Email : Dbox@nightstick.com Web : https://nightstick.comFrom 125 kg/hr to 19,000 kg/hr we have the right industrial boiler for you

All boilers are designed and manufactured to order, ensuring you have full control over the specification from start to finish.

Our range of industrial steam and hot water boilers are available to order in sizes from 125 kg/hr up to 19,000 kg/hr, suitable for an array of applications.

From our Peaksman vertical steam boiler through to our bespoke waste heat recovery steam boilers and Unity boiler house control system, all our products are designed and manufactured in the UK by our team of industry experts.

Need a reliable industrial boiler from a brand you can trust? No matter what your steam or hot water requirements are, we can provide a solution that will fit your needs.Integrated Global Services, Inc. (IGS) is an international turnkey provider of surface solutions for mission-critical equipment.

IGS engineers its own solutions to corrosion, erosion, and fouling-related instabilities. This includes a proprietary High Velocity Thermal Spray (HVTS) coating system to stop corrosion and erosion in a variety of mission-critical assets.

IGS deploys a range of services designed to improve the efficiency of fired heaters delivering increased capacity, up to 15% CO2/fuel reduction and 30% less NOx. Cetek ceramic coatingsoptimize radiant efficiency and increase throughput in fired heaters, while our Hot-tek™cleaning, repair, and inspection services rapidly solve fired heater related emergencies online. Tube Tech services achieve a 90%+ clean convection section while Environmental solutions optimize SCR efficiency while eliminating downtime.

IGS has the largest global footprint in the heavy industry sector, with operational capabilities and experience delivering solutions on-site on six continents.

Contact Details Tel : 001 8885062669 Fax : Email : mailto:info@integratedglobal.com Web : https://integratedglobal.comKings are the UK’s largest and longest established international supplier of industrial Steam and Hot Water boilers for replacement, temporary hire and servicing, available nationwide.

Our fleet of temporary steam boilers range from 340kg/hr (750lb/hr) to 15,800 kg/hr (35,000lb/hr) comprising trailerised, containerised or static boilers that are oil, gas or dual fuel with pressures up to 12 bar.

Our fleet of temporary hot water boilers range from 94kW (320,000 btu) to 8,000 kW (27,000,000 btu) and include a range of containerised or static low-pressure units, with oil, gas or dual fuel.

Steam and Hot Water Boilers for Purchase

Kings have boilers for sale for any size project with fast, nationwide delivery. We have an unrivalled choice of modern steam and hot water boilers in stock, ranging from 340kg/hr to 16,000kg/hr steam and 150kW to 7,500kW hot water with working pressures from 7bar to 18 bar. Our fully re-furbished boilers save businesses time and money over new.

Contact Details Tel : +44 01992 451629 Fax : Email : Marketing@thekinggroup.co.uk Web : https://www.kingsboilerhire.co.uk/ Tracey Parker Marketing ManagerFounded in 1983 Rotech Systems Manufacture and supply worldwide, high quality, high reliability equipment for monitoring and measuring the speed, position and direction of rotating shafts.

Rotech Systems are the world’s leading manufacturer of high quality monitoring solution products with an unparalleled reputation for reliability, durability and quality.

Major features are tough, strong, heavy duty construction, designed to operate and give years of maintenance free operation in even the harshest industrial environments, quarries, mines, etc. and simple, quick, installation.

Main applications are in the bulk handling and processing industries. Protecting conveyors, elevators, screws, crushers, mixers, etc. anywhere were slowing down or stoppage will cause product spillage, blockage, etc. and incur downtime, lost production, cleaning up, spoilt product, etc.

Equipment can give visual and/or audible alarms plus shutdown items of plant for a speed reduction of only 5% (adjustable 5% to 90%)

Protects against conveyor belt slip, v belt slip, chain breakage, mechanical failure, stoppage, blocking, jamming, etc.

Industries using “Rotech”: Food, Textiles, Glass, Grain, Power generators, Fertiliser, Sand, Gravel, Roadstone, Coal, steel, Ore.

Wherever materials are transported or processed by Conveyors, Elevators, Screws, Crushers, Mixers, Etc, there are applications for “Rotech” Motion Sensors/Encoders.

Food, Grain, Pharmaceuticals, Chemicals, Sand, Stone, Cement, Ore, Coal, Ash, in Factories, Quarries, Mines, Power Utilities, and Dock Installations are all excellent examples.

A single conveyor may run for long periods without any problems, but not forever, the day arrives when it starts to slip or slow down and unless action is taken quickly to switch off the conveyor, crusher or plant that feeds it then a major spillage can occur.

In a large plant with many conveyors and drives the potential for problems is multiplied by every additional drive element.

The costs of clearing up a spillage are not simply the costs of a man with a shovel, this is the tip of the iceberg, they can include:

The “Rotech” range of Monitoring Equipment is comprised of a range of Motion Sensors/Encoders, Vibration Sensors and associated Speed Relays.

The Heavy Duty Sensors are installed on the end of the shaft or on the belt being monitored. They send an electrical signal proportional to the speed of the shaft/belt to a suitable control unit.

The control unit can be a “Rotech” Speed Relay, a Programmable Controller, a Computer, Data Logger device or other proprietary control equipment.

The alarm level of the control unit is set to just below the normal running speed of the shaft.

In the event of the shaft/belt slowing below the set level, the control unit operates and can be connected to give an alarm to the operator and/or shutdown preceding items of plant.

“Rotech” heavy duty motion sensors and encoders combine many unique design features to give

the customer:-

For shaft encoders one hole is drilled and tapped into the end of the shaft to be monitored, gives simple, uncomplicated, fast installation.

One type of unit covers all types of drives, conveyors, elevators, crushers, etc. allowing standardisation of designs, installation and spares.

No target discs to design, manufacture and install.

No sensor brackets to design, manufacture and install.

No guards to design, manufacture and install.

No on – plant adjustment or setting up required.

The “Rotech” unit is carried on the shaft and moves with it, it is unaffected by shaft end float, belt adjustment, etc.

If the end of the shaft is inaccessible our wheel encoders can be used directly on the belt.

A piece of unistrut is bolted to two uprights across the return belt, then the wheel encoder is bolted to the centre of the unistrut using the integral bracket, this bracket allows the wheel encoder to hang down on to the return belt and move freely with the belt.

Again one type of unit covers all types of drives, conveyors, elevators, crushers, etc. allowing standardisation of designs, installation and spares.

No target discs to design, manufacture and install.

No sensor brackets to design, manufacture and install.

No guards to design, manufacture and install.

No on – plant adjustment or setting up required.

“Rotech” Motion Sensors/Encoders are digital pulse generators guaranteed accurate to within 0.5%, they cannot drift and require no checks or periodic calibration.

With pulse output rates from 1 Pulse per Rev to 1000 Pulses per Rev, drive speeds from 5000 RPM down to 0.03 RPM (2 Revs/Hour) can be accurately and reliability measured and monitored.

“Rotech” units are designed to operate and survive in even the toughest industrial environments, they have been particularly developed for the Quarrying and Mining industries, however their compact size makes them just as suitable for light industries such as :-

Food Production, Animal Feeds, Farming, Pharmaceutical, Baggage Handling, Escalators & Moving Walkways, etc.

Heavy Duty castings, Heavy Duty sealed bearings and robust fully encapsulated industrialised electronics form the tough strong core of these units.

Extensive use is made of modern engineering adhesives and sealants to double up on the traditional precision assembly methods and ensure even greater reliability.

‘O’ ring seals on end covers, grease chambers, spring loaded shaft seals and liquid tight flexible conduit and glands complete these units to give outstanding levels of protection and ensure the highest levels of reliability and operational life.

Installed price is competitive or possibly lower than alternative methods, ultimate! in operational life and reliability is an added bonus

Contact Details Tel : (0)151 356 2322 Fax : Email : sales@rotechsystems.co.uk Web : https://rotechsytems.co.ukPEMAC is a dedicated Computerised Maintenance Management System (CMMS) that helps companies reduce equipment breakdowns by analysing the reasons for failure and informing decision making. Through its premium CMMS solution, PEMAC Assets, PEMAC delivers powerful features and benefits. PEMAC also offers the option to integrate its health and safety software and paperless approval tools with its CMMS ensuring that client key assets, people and equipment are aligned in delivering a successful maintenance strategy. PEMAC has over 30 years’ experience in the pharmaceutical, medical devices, utilities, and food and beverage industries. The company has worked with some of the world’s top brands including Leo Pharma, Aga, and Heineken.

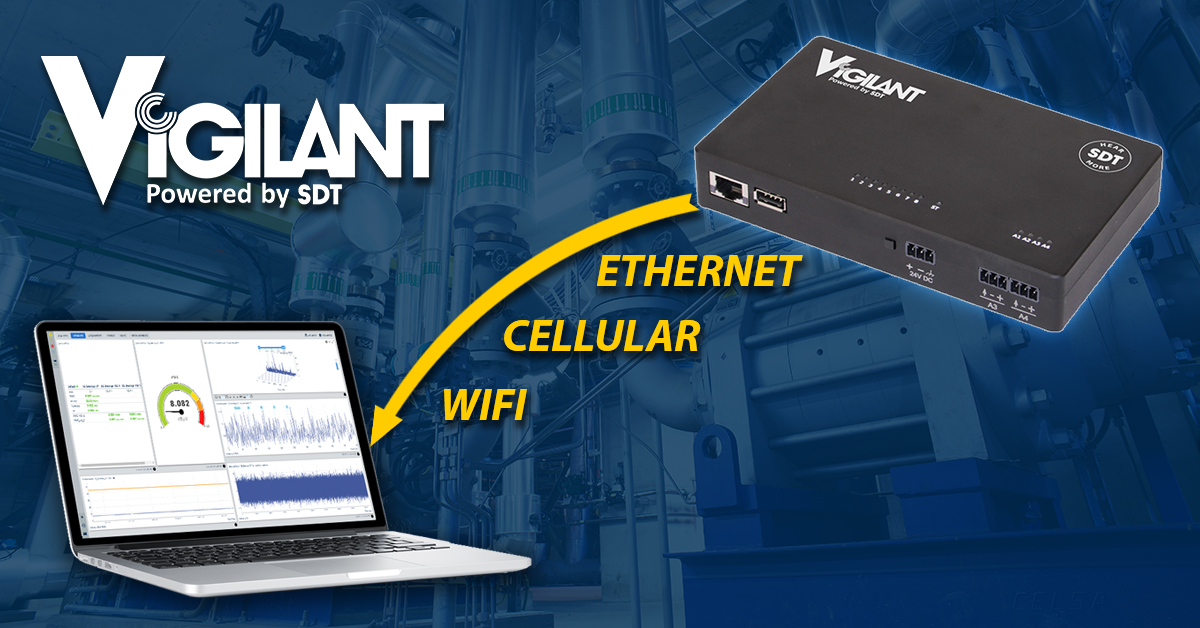

Contact Details Tel : (+353) 1 466 3888 Fax : Email : sales@pemac.com Web : https://pemac.comSDT provides ultrasound solutions that help our customers gain a better understanding about the health of their factory. We help them predict failures, control energy costs, and improve product quality while contributing to the overall reliability of their assets.

Ultrasound is used in predictive maintenance and asset reliability as the first line of defense against unexpected breakdowns and shutdowns. This versatile technology can be applied to:

The SDT range is designed to offer simplicity to those who need it, and sophistication to those who want it. It is made up of intelligent, advanced instruments, equipped with powerful database management software as well as packages to meet the specific needs of specific applications. With these solutions, SDT brings equipment reliability and sustainability within everyone's reach.

Follow us on InstagramFollow us on Instagram

Contact Details Tel : 32 2 332 32 25 Fax : Email : info@sdtultrasound.com Web : https://sdtultrasound.com

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE