In the field of condensate technology, there is also news at the COMVAC HANNOVER 2013 at BEKO TECHNOLOGIES: the upgrade version of the BEKOMAT 31, 32, and 33 condensate drains with improved serviceability.

In the field of condensate technology, there is also news at the COMVAC HANNOVER 2013 at BEKO TECHNOLOGIES: the upgrade version of the BEKOMAT 31, 32, and 33 condensate drains with improved serviceability.

The upgrade version of the BEKOMAT 31/32/33 series has an integrated service indicator which informs you of upcoming maintenance in a timely manner. The employment of a multi-voltage power supply unit for the energy supply from 85 to 265 Vac, at 50-60Hz, reduces the variants. With the higher protection class IP67, the condensate drains are not only reliably protected against the admission of dust, they are also sealed to such an extent that temporary submersion in water will not damage them. Therefore, they are an ideal solution for the most severe ambient conditions.

Compressed air is said to be responsible for approximately 10% of the power usage in the UK and other mature economies. BEKO TECHNOLOGIES are a leading company in the treatment of compressed air and management of condensates. Another major part of the business is measurement systems. BEKO TECHNOLOGIES are well equipped with experienced technical sales personnel to help businesses improve their efficiency of compressed air usage. We have put together a list of top tips:

Compressed air is said to be responsible for approximately 10% of the power usage in the UK and other mature economies. BEKO TECHNOLOGIES are a leading company in the treatment of compressed air and management of condensates. Another major part of the business is measurement systems. BEKO TECHNOLOGIES are well equipped with experienced technical sales personnel to help businesses improve their efficiency of compressed air usage. We have put together a list of top tips: A & B Air Systems and BEKO TECHNOLOGIES have helped lower costs at a leading European food manufacturer. Their customers are most of the leading high street food chains.

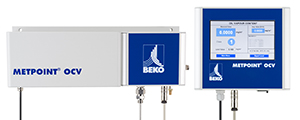

A & B Air Systems and BEKO TECHNOLOGIES have helped lower costs at a leading European food manufacturer. Their customers are most of the leading high street food chains. Compressors are responsible for 10% of all the power consumed in a mature industrial society like the UK and Ireland. Frequently 10% or more of this air will be wasted because of leakage caused by poor maintenance, bad design of air lines, acidic condensate attacking seals and joints just to name a few of the possibilities. Therefore it makes sense to do regular audits on the power consumed, flow, pressure, dew point and leakage as a starting point. Is this commonly done? Matthew Harrison, Regional Sales Manager at BEKO TECHNOLOGIES says, “No this type of extensive measurement is rare but smart companies are realising that you can’t know too much about what is happening within your compressed air network. You can avoid problems and be sure that you are operating to an efficiency that is acceptable if you regularly even better have a permanent output of key parameters within the system. Now that the BEKO Data Logger is available it is very easy for me and BEKO TECHNOLGIES colleagues to monitor up to 12 outputs per BDL installed which is plenty for the normal compressed air system.

Compressors are responsible for 10% of all the power consumed in a mature industrial society like the UK and Ireland. Frequently 10% or more of this air will be wasted because of leakage caused by poor maintenance, bad design of air lines, acidic condensate attacking seals and joints just to name a few of the possibilities. Therefore it makes sense to do regular audits on the power consumed, flow, pressure, dew point and leakage as a starting point. Is this commonly done? Matthew Harrison, Regional Sales Manager at BEKO TECHNOLOGIES says, “No this type of extensive measurement is rare but smart companies are realising that you can’t know too much about what is happening within your compressed air network. You can avoid problems and be sure that you are operating to an efficiency that is acceptable if you regularly even better have a permanent output of key parameters within the system. Now that the BEKO Data Logger is available it is very easy for me and BEKO TECHNOLGIES colleagues to monitor up to 12 outputs per BDL installed which is plenty for the normal compressed air system. The uses of compressed air are pretty much universal from pumping up your car tyres to sophisticated control systems for industrial processes. In the medical sphere compressed air is used to operate simple mechanical devices such as drills and saws, ventilators and as a carrier gas in anaesthesia and inhaled medications. Compressed air at source is ambient air which has passed through a mechanical device(the compressor) which in industrial applications sometimes comes into contact with the lubricating oil. In more “quality” applications the compression chamber is usually dry of any lubricating medium.

The uses of compressed air are pretty much universal from pumping up your car tyres to sophisticated control systems for industrial processes. In the medical sphere compressed air is used to operate simple mechanical devices such as drills and saws, ventilators and as a carrier gas in anaesthesia and inhaled medications. Compressed air at source is ambient air which has passed through a mechanical device(the compressor) which in industrial applications sometimes comes into contact with the lubricating oil. In more “quality” applications the compression chamber is usually dry of any lubricating medium.  Andrew Stanley is appointed Regional Sales Manager for Ireland and the East Midlands. This is a new position created by growth in the Midlands area and the need to provide more support into the Irish Market. Andrew has a BSc from Brunel University and after a short career in retail where he quickly became a store manager for Lidl, he joined Ultrafilter, now Donaldson, and remained with them for 9 years achieving the status of top salesman in the UK on 4 occasions.

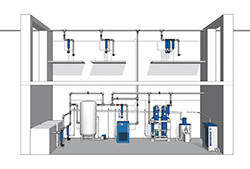

Andrew Stanley is appointed Regional Sales Manager for Ireland and the East Midlands. This is a new position created by growth in the Midlands area and the need to provide more support into the Irish Market. Andrew has a BSc from Brunel University and after a short career in retail where he quickly became a store manager for Lidl, he joined Ultrafilter, now Donaldson, and remained with them for 9 years achieving the status of top salesman in the UK on 4 occasions.  BEKO TECHNOLOGIES has helped one of the largest car manufacturing plants in the UK, based in the North East of England. The customer approached BEKO TECHNOLOGIES following a supplier recommendation as they were looking to replace the existing dryers which were also due an overhaul. We felt that the refurbishment was not a very cost effective method as the existing equipment would still be costly to operate even after a major overhaul. BEKO TECHNOLOGIES offered a solution to replace this equipment with "zero-purge" desiccant dryers that would reduce running costs significantly and offer improved air quality.

BEKO TECHNOLOGIES has helped one of the largest car manufacturing plants in the UK, based in the North East of England. The customer approached BEKO TECHNOLOGIES following a supplier recommendation as they were looking to replace the existing dryers which were also due an overhaul. We felt that the refurbishment was not a very cost effective method as the existing equipment would still be costly to operate even after a major overhaul. BEKO TECHNOLOGIES offered a solution to replace this equipment with "zero-purge" desiccant dryers that would reduce running costs significantly and offer improved air quality. On September 17th 2012 the new production facility in China was successfully established.

On September 17th 2012 the new production facility in China was successfully established.