More Editorial

Directory

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE

The A' Award and Competitions board are happy to inform that the Prisma project by L A Design & Sonatest Ltd wins the noted Platinum A' Design Award at Scientific Instruments, Medical Devices and Research Equipment Design Competition.

The A' Award and Competitions board are happy to inform that the Prisma project by L A Design & Sonatest Ltd wins the noted Platinum A' Design Award at Scientific Instruments, Medical Devices and Research Equipment Design Competition.

The A' Award and Competitions board are happy to announce that the project "Prisma" by Pete Holdcroft - LA Design, Matthew Brown - LA Design, Stewart Lamont - Sonatest Ltd and YvanGosselin - Sonatest AP has been awarded the Platinum A' Design Award in the Scientific Instruments, Medical Devices and Research Equipment Design category of competition. This project was selected as a winner by the international awarding commission of the A' Design Awards & Competitions Board's members.

Product Designers LA Design, who have partnered Sonatest Ltd in product design projects previously, outlined to the panel that the “Prisma is designed for non-invasive material testing in the most extreme environments. It is the first detector to incorporate advanced real-time imaging and 3D scanning, making flaw interpretation much easier, reducing technician time on site. With a virtually indestructible enclosure and unique multiple inspection modes, Prisma can cover all testing applications, from oil pipelines tohigh end aerospace components. It is the first detector with integral data recording, and automatic PDF report generation. Wireless and Ethernet connectivity allow the unit to be easily upgraded or diagnosed. ” Learn more about the award winning design and submission via the Prisma page on the A Award Website .

Platinum A' Design Award

The Platinum A' Design Award is a prestigious award given to top 1% percentile designs that has delivered an exemplary level of quality in design. The designs are judged by a panel of three different juries which are composed of Academic, Professional and Focus Group Members. The designs are evaluated using score normalization to remove any biases. Votes are cast on aspects such as functionality, ergonomics, engineering, presentation, innovation, usability, fun details, technology. Other specific points tare also considered, each of these points are further weighted via different jury groups.

The A'Design Award and Competitions aim to highlight the facets and features of best design, design concepts and design oriented products. The A' Design Award and Competitions are organized and awarded annually and internationally in multiple categories to reach a wide, design-oriented audience.

Find out more:

Sonatest Ltd.

www.sonatest.com

Tel: 01908 525904

Problem:

A major Oil and Gas Company, with oil and gas well sites located in the Texas Panhandle and Western Oklahoma, was experiencing problems with their above ground storage tanks due to heavy production and sour crude. Most of the tanks were found to have internal corrosion within the lower 8" of the tank shell. In addition, this company did not have an accurate inventory of the equipment at the well sites. The company wanted the lower 16" of each tank shell circumference at each well site to be 100% inspected.

Figure 1: Typical Tank Battery

Solution:

Beginning on March 20th, 2006 TesTex, Inc. partnered with Premier NDT Services to provide inspection services for approximately 2,200 Above Ground Storage Tanks at approximately 1,700 different locations in the Texas Panhandle and Western Oklahoma for this major Oil and Gas Company. These storage tanks contained Crude Oil, Produced Water, and Natural Gas Condensate.

Prior to starting the project, TesTex, Inc. produced (6) PS-2000 Systems, (4) 8" Low Frequency Electromagnetic Technique (LFET) Scanners. Premier NDT Services established a field office in Perryton, Texas. TesTex Inc. and Premier NDT Services staffed (15) people to man this project.

Three inspection teams were formed consisting of employees from both TesTex, Inc. and Premier NDT Services. The Oil and Gas Company provided the inspection teams with a master site list with latitudinal and longitudinal coordinates to the sites. Each site consisted of 0-4 tanks and sometimes more. This list was plotted into a GPS program on each team's laptop computer for navigational purposes.

Problem:

A large chemical plant in Eastern Tennessee was experiencing a number of tube leaks in one of their boiler generating banks. The cause for the failures consisted of two specific flaw mechanisms revealed through destructive tube samples, which are listed below:

ID pitting as small as 3/16" diameter occurring between the mud drum tubesheet and mud drum bend, which was mainly found on the cold side.

ID longitudinal grooves as small as 1/8" in width located between the steam drum tubesheet and steam drum bend was found on the hot side tubes.

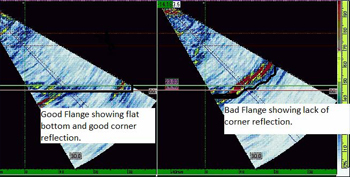

Our Omniscans are the ideal solution for flange face corrosion inspections utilizing phased array techniques. Depending on the inspection requirements, Oceanscan can provide either an Omniscan 1664 for simple image capture reporting or an Omniscan 16128 for full encoded data capture analysis. Oceanscan has the technology.

Our Omniscans are the ideal solution for flange face corrosion inspections utilizing phased array techniques. Depending on the inspection requirements, Oceanscan can provide either an Omniscan 1664 for simple image capture reporting or an Omniscan 16128 for full encoded data capture analysis. Oceanscan has the technology.

Three tried and tested probe positions are on the flange tapper, between the bolt holes and on the outer rim, illustrated below. The shear wave inspection is usually carried out from 35 to 70 degree when fitted with a 55 degree wedge; data is displayed in S-Scan.

TURN-KEY-KITS;

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE