In the context of Condition Based Maintenance (CBM) it is generally accepted that measuring the vibration of a rotating machine (motor, pump, fan etc.) will tell us something about the condition of the machine. But what exactly are we measuring and what does it tell us about the machine?

Basically, it boils down to two numbers. One is the average (RMS) value of the low frequency vibration that tells us something about how well the machine is running. The other is the average value of the high frequency vibration that tells us something about the condition of its bearings.

The low frequency vibration is the typical “hum” you hear from a rotating machine. This vibration is due to the centrifugal force resulting from any out-of-balance in the machine. Since it is virtually impossible to exactly align a machine’s centre of gravity with its centre of rotation, even a well-balanced machine will still vibrate or “hum”. But what is an acceptable level? This is where the International Standards Organisation (ISO) comes to our aid. ISO have produced a set of guidelines that define suitable levels of machine vibration in the frequency range 2Hz to 1kHz (120 RPM to 60,000 RPM). That frequency range being chosen because it covers the vast majority of machine running speeds normally encountered.

The high frequency vibration is the typical “whine” you hear from a badly worn bearing. In practice, it is there all the time but is inaudible until the bearing becomes so bad it is probably about to fail. Fortunately, a vibration analyser can detect the inaudible bearing noise well before it gets to that point. This means bearing wear can then be displayed, for example, in Bearing Damage Units (BDU) that can very roughly be thought of as a “percentage” of bearing wear.

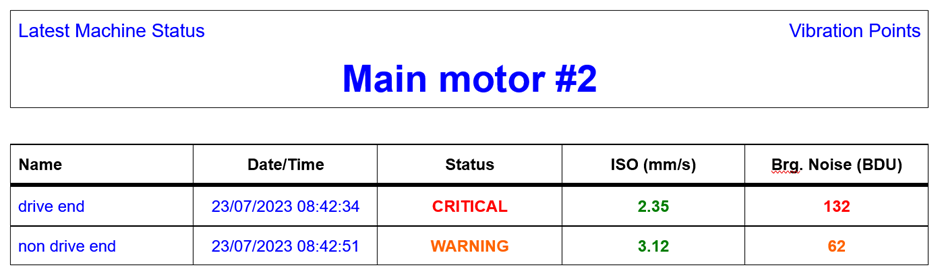

Vibration analysers employ sensors to capture a vibration waveform from a machine and then analyse it to automatically generate the ISO reading and the bearing condition. It is largely this ability that distinguishes them from simple vibration meters. The readings below, taken from a typical VibTrend report, show vibration levels measured on a motor. The ISO readings appear in green as they are below the recommended 4.5mm/s ISO warning level for a medium size motor. However, the drive end bearing noise is displayed in red as it is above the specified 100 BDU critical alarm level. The high BDU reading was in fact due to an outer race defect on the drive end bearing.

Test Products International manufactures a complete range of low-cost, high-performance vibration analysers from the £575, one-button-to-press TPI 9070, to devices that include advanced diagnostic and machine balancing capability. The TPI 9070 features colour coded alarm levels and zoomable on-screen vibration frequency plots together with on-meter analysis for the detection of machine faults such as unbalance, misalignment, looseness and bearing wear.

The TPI 9080 from £1,100 comes complete with VibTrend PC based trending and reporting software that includes automatic report generation and email notification of alarms, implementing a full CBM solution. The TPI 9080 can store lists (routes) of machines (up to 1000), each with up to 10 measurement points, all with full vibration waveform and frequency spectrum (FFT) capture.

Routes and readings can be transferred between the TPI 9080 and the included, license free, VibTrend in a variety of different ways. Via the included USB docking cradle, wirelessly via Bluetooth or remotely via a Bluetooth link with a smart phone or tablet running the free TPI Bridge App. This allows service personnel to receive and return routes and readings, no matter where they are in the world.

For more information please contact TPI Europe’s head office on +44 1293 530196 or take a look on the website at www.tpieurope.com or email This email address is being protected from spambots. You need JavaScript enabled to view it.