One City Global have just launched their Predictive Maintenance Solution which with its machine learning capabilities brings far more efficiency and accuracy to your maintenance systems.

This cutting-edge solution is set to revolutionize industrial maintenance practices, enabling businesses to optimize their operations, reduce costs, and enhance overall equipment reliability.

Traditional maintenance practices have often relied on reactive or scheduled maintenance, leading to potential downtime, unplanned expenses, and inefficiencies. One City Global's Predictive Maintenance technology takes a proactive approach, harnessing the power of artificial intelligence to forecast and prevent equipment failures before they occur.

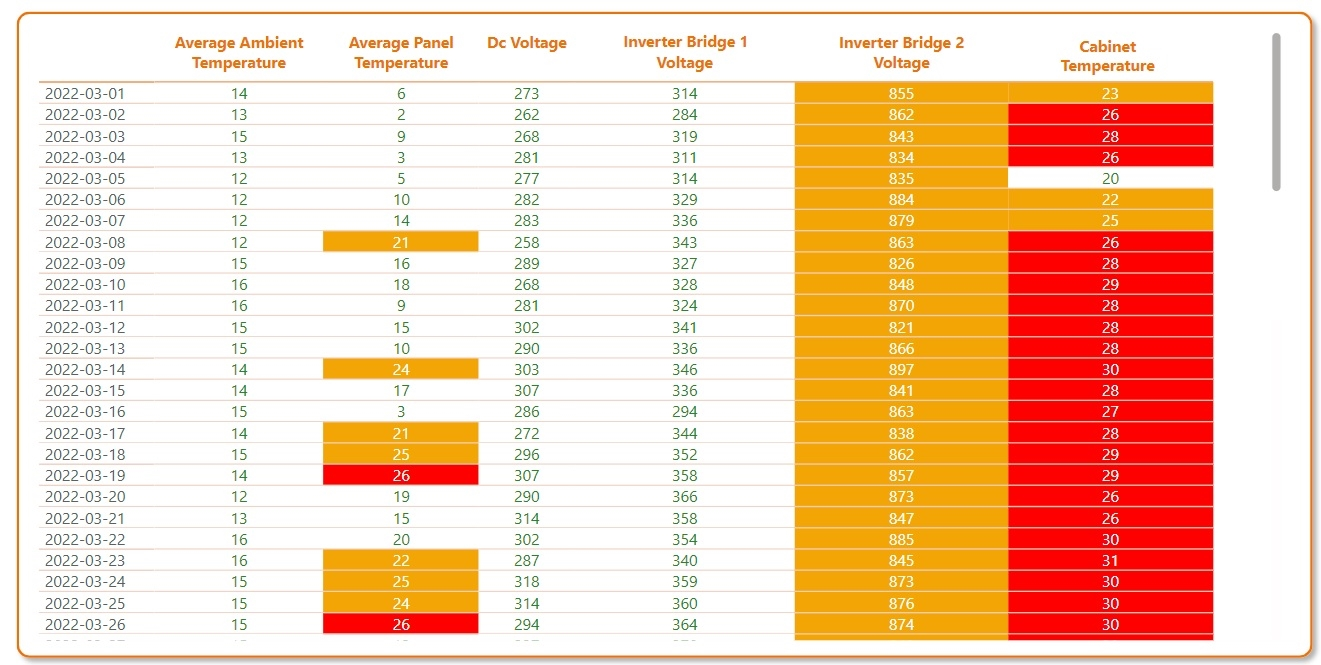

Using a combination of machine learning algorithms and data analysis techniques, One City Global's Predictive Maintenance solution continuously monitors the performance of critical machinery and systems. By analysing historical and real-time data, the technology can identify patterns, anomalies, and indicators of potential issues that may lead to failures or breakdowns.

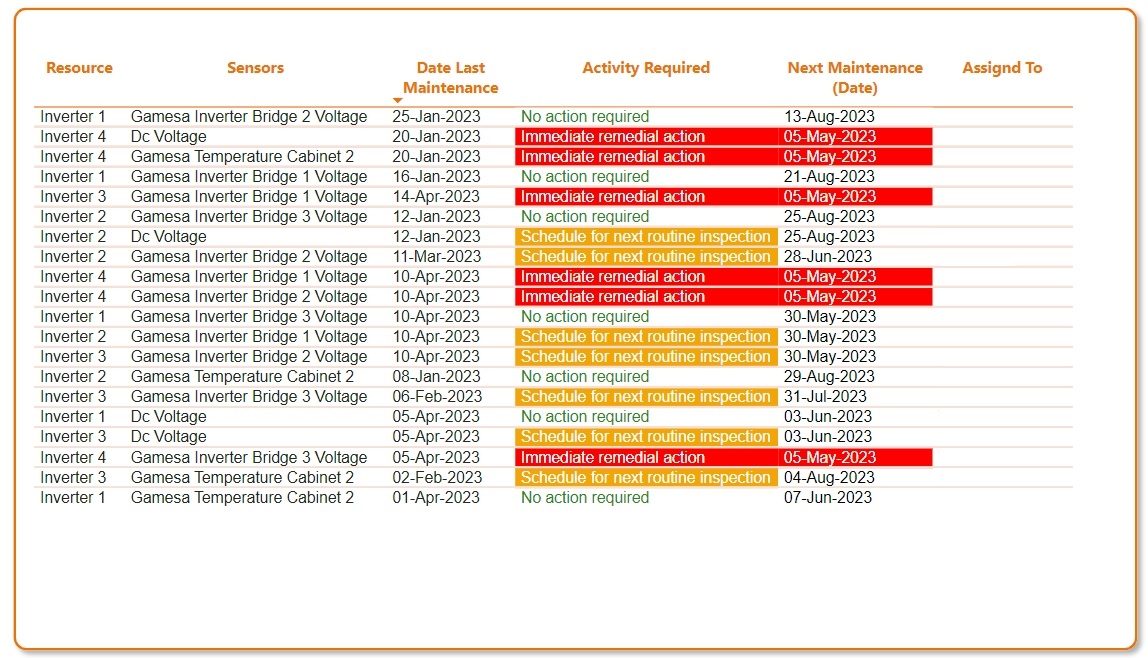

The system includes a number of configurable dashboards that allow users a quick overview of the data to help make informed decisions or act quickly if a situation requiring rapid intervention occurs.

Key Features and Benefits of One City Global's Predictive Maintenance Solution:

- Early Fault Detection: identify subtle changes in equipment behaviour and detect potential faults or anomalies at an early stage, allowing for timely interventions to prevent failures.

- Optimal Maintenance Planning: accurately predict equipment maintenance requirements, to plan and schedule maintenance activities more efficiently, minimizing disruptions to operations and reducing unnecessary maintenance costs.

- Increased Equipment Reliability: proactive maintenance measures can maximize the lifespan and reliability of machinery, avoiding costly downtime and improving overall operational efficiency.

- Cost Reduction: help eliminate unnecessary maintenance tasks, optimize resource allocation, and reduce overall maintenance costs.

- Data-Driven Decision Making: leverage the power of data analytics and machine learning, to gain valuable insights into equipment performance, to enable informed decision-making for maintenance strategies and resource allocation.

One City Global's Predictive Maintenance technology is designed to be adaptable and customizable to various industries, including manufacturing, energy, transportation, and more. The solution integrates seamlessly with existing systems, making it accessible and practical for businesses of all sizes.

“Significant savings of around 10-30% reduction in inventory levels, and around 5-15 % reduction in downtime can be realised through minimising equipment maintenance time and lost production hours. In addition to this a reduction of around 3-5% in new equipment costs are achievable.” (source Deloitte Development LLC)

To learn more about One City Global's Predictive Maintenance technology and its transformative impact on industrial maintenance, please visit www.onecityglobal.com or email us at This email address is being protected from spambots. You need JavaScript enabled to view it..