Spare parts are the lifeblood of operational reliability and plant capacity.

Spare parts are the lifeblood of operational reliability and plant capacity.

No plant can operate at a high level of output without a reliable supply of functional spare parts. Spare parts form the bedrock on which operational reliability is built and this requires appropriate storage, treatment of, and timely access to the required parts. Yet, spare parts are also the most overlooked contributor to reliability outcomes. Read More

Our research has shown that many companies routinely operate without properly implementing even the most fundamental aspects of spare parts management at their sites. Often these companies have storerooms with neat shelves and clear labels but this is not enough for highly reliable spare parts management. To help make a difference in your operational reliability here are six tips to improve your spare parts management.

Tip #1: Develop Clear Spare Parts Stocking Criteria

To stock or not to stock, that is the question. One of the major flaws in most spare parts management systems is the absence of clear criteria on when to stock an item and when not to stock an item. The absence of any guidelines forces your team into a process of ad hoc and inconsistent decision making. The result of this is that you stock items that don’t require stocking and don’t stock items (sometimes critical items) that you should stock. To avoid this you need to develop and implement specific guidelines to aid decision making on when to stock an item and when to not stock an item.

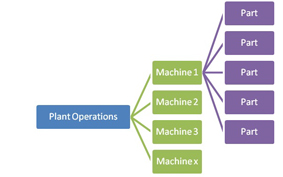

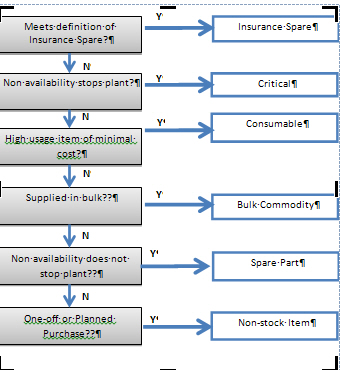

Step one for implementing this is to determine a series of stock categories that enable clear separation of stock types. Figure 1 shows a logical approach for identifying categories.

Step two is to use a series of structured questions to explore the alternatives. For example:

- Is the item obsolete or likely to be obsolete in 6 months time?

- Can we use something else that we have in stock (substitution)?

- Can usage be planned within the supply lead time (forecast usage)?

- When required can the item be delivered by a vendor in an acceptable lead time (quick/local delivery)?

- Can the asset in service be repaired in an acceptable lead time (repair rather than replace)?

- Is the item being ordered for a project (not stocked)?

- Can the need for the item be eliminated (engineered out)?

- Can we use someone else’s stock (share/pooling)?

Tip #2: Provide Clear Guidelines on How Many Parts to Stock

Once you have established clear spare parts stocking criteria the next step is to establish clear guidelines on how many of an item to stock. By developing and implementing clear stocking guidelines you provide the logic for decision making on stock levels and calculating reorder quantities. The advantage of this is that it provides guidance to your team, continuity for decision making, and provides the basis for future audits of inventory holdings.

For example, you may choose to apply appropriate calculation tools or you may choose to provide a series of basic guidelines based on anticipated usage. In both of these cases, the application provides direction and the result can be audited.

Tip #3: Accept that Some Stock Outs are OK

One of the main fears of most reliability and maintenance engineers is that, at the time of actual need, the required spare part will not be available. This is commonly referred to as a stock out. But how do you eliminate all stock outs? The short answer is that you can’t, not without tying up massive amounts of money that would be better used elsewhere. Even then, I am not sure that you could guarantee eliminating all stock outs. This would possibly require holding multiple units of every part in your plant. That’s not viable. That’s the truth. What you can do is accept stock outs in areas where they have little or no impact or where a viable supply alternative exists. Then work to eliminate stock outs for the items that really matter.

There are essentially two causes of stock outs. The holding parameters may have been incorrectly set for the demand that is experienced, or at least are not correct for the current level of demand. Or, there is some delay in the demand or supply chain, including the internal processes associated with purchasing. When measuring stock outs it important to differentiate between these different causes. This is because adjusting your stock levels (usually upwards) to account for a temporary supply event may not be the best course of action.

One quick and easy way to collect a record of stock outs and enable follow up to root cause is to go retro and use some old fashioned technology – a clipboard! At most locations the stock out rate is unlikely to be so high that it would need any automated solutions to collect data (and in any case how do you automate not having something?), so a good old fashioned clipboard works well.

All you need is a form with headings such as part no., description, date, person requesting the part, and likely cause of the stock out and you will instantly create a record and get a real time report. The form acts as the report.

Tip #4: Review the Holdings of Critical Spare Parts

Maintenance and reliability engineers will happily (well, not happily) undertake a review of spare parts that are not classified as critical, yet they will shy away from reviewing items that are classified as critical. The argument is: ‘the item is critical and so we must stock it’. Thus the classification drives the review action rather than a cost benefit or stocking analysis. But what if the classification was wrong, or the item was significantly overstocked, or the supply arrangements had changed? Surely these are factors that can be reviewed and have nothing to do with the part’s criticality? It doesn’t make sense to limit your reviews based on the idea of criticality. This will drive you to review parts that are critical but not defined as such and not review parts that are defined as critical but which may no longer be critical. Critical parts may be just as overstocked as any other item, or there just might be a viable alternative to holding the item at all.

It is also important to recognize that criticality is not a single dimension issue, that is, an item either is, or isn’t, critical. Spare parts criticality is a multi-dimensional issue.

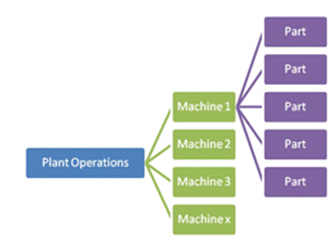

By multi-dimensional I mean that criticality has a number of characteristics that need to be considered before deciding what to hold in inventory. For example, is the item in question machine critical or operationally critical? By machine critical I mean, will failure of the item stop the piece of equipment of which it is a part? By operationally critical, I mean, will failure of the item stop production? These two characteristics are quiet different and have a different impact on what to do next. To support this analysis you need to understand your part/machine/operations hierarchy, as shown in Figure 2.

The impact of not holding a required spare part can be massive. Downtime costs often far outweigh the purchase and holding costs of spares and this can lead to holding far more of some spares than is really required. As a result accountants will often target this as an area of easy cost savings. If you want to keep the accountants off your back and maintain control of your spares holdings it is important to regularly review your inventory and eliminate excess spare parts holdings. To do this most effectively inventory reviews need to focus on much more than just data analytics. The real drivers of excess inventory lay in the processes and decision making that influences your inventory levels, with the most common culprit being the returns process.

If you want to improve the management of rotable and repairable parts you should:

- Track the status of the item. For successful management you must know if the item is ready for use, awaiting repair (or batching), or undergoing repair.

- Determine in advance your rules for whether to repair or purchase. To do this you need to consider issues such as the cost of repair vs. the cost of purchase, the functionality following repair, whether the item will provide the reliability performance you require, lead times for both repair and supply, dependent demand for components, the number of items in the system, and so on.

- Let the accountants worry about the cost allocation. The question that I am most often asked about rotable and repairable items is ‘what is the right way to allocate the costs?’. My response is for both maintenance and storeroom personnel to focus more on tracking and repair/replace decisions than the cost allocation, as this is usually where the management of rotable items and repairable spare parts goes wrong. Yes, cost issues will drive behavior but the key is to ensure a reliable supply of spare parts.

Tip #6: Review Your Storeroom Security

Many companies are fully aware of the importance of maintaining security around their spare parts inventories. They secure their spares in lock-up areas, ensure staff are on hand to manage the level of spares requests during periods of high maintenance activity, and provide a rock solid approach for identifying storeroom entrants during the afternoon and night shifts. Then they leave the back door open! To ‘make life easier’ there is often a gate left open through which anyone can enter. While the efficiency in terms of supplying spares and minimizing downtime is obvious, this practice actually puts your reliability at risk. Removing items from the storeroom without proper record, no matter how honest the intent, will not trigger reordering when required and next time you need that item it will not be in stock.

If you think for a moment about the cause of inaccurate stock level data you quickly realize that there really are only a few drivers and two of the main ones are:

1. Items being taken (or picked) without being recorded

2. Items being placed into the store, either from a new delivery or via a return to store, without being recorded

By not paying sufficient attention to storeroom security companies effectively leave their inventory data management in the hands of non stores personnel who may be more concerned with other issues rather than storeroom documentation.

Spare parts management is like every other aspect of operations management: success requires clear guidelines, differentiation of outcomes, critical evaluation, and discipline in execution. Efficient and effective spare parts management requires more than having storerooms with neat shelves and clear labels, it requires forethought and attention to the key decision making points and consistency requires a documented approach that you are able to audit and report on. Only by taking such an approach can you ensure the optimization of working capital requirements and that you hold the right parts for operational needs. Following these six spare parts management tips will take you a long way to achieving the operational reliability that you need.

Phillip Slater is a leading authority on materials and spare parts management. He is a qualified engineer, an experienced operations and maintenance manager, a seasoned consultant, and the author of four operations management books, including Smart Inventory Solutions, now in its second edition. Since 2001, Phillip has provided inventory management consulting, advice, and training to more than 300 companies, managing more than 1,000 storerooms, holding $3.5bn in inventory. For more information on spare parts management visit Phillip’s website www.PhillipSlater.com.