The youngest ever member of the Water Jetting Association is championing the promotion of his industry to talented young engineers and technicians.

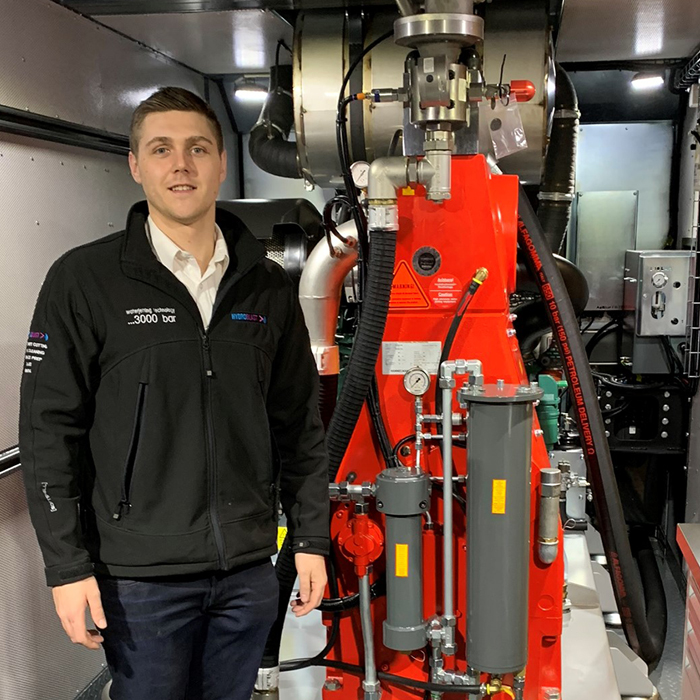

Ross McDonald, aged 28, became a member of the Ruling Council of the Water Jetting Association (WJA) in 2018. He has also been a member of its Technical Committee since 2016.

The WJA, the member organisation for the water jetting industry, has just marked the 40th anniversary of its foundation in October 1980.

Ross McDonald, Operations Director at water jetting contractor Hydroblast, in Northallerton, North Yorkshire, now wants to showcase the industry to bright and talented young engineers and technicians.

He said: “The WJA has done a good job to get us to our 40th anniversary. To realise the full benefits of advances in the quality, safety and capability of water jetting technology, we need to refresh our vision and goals in line with future challenges and younger generations.

“Many young people have different ways of working and, perhaps, broader expectations. It’s something I will be encouraging as we enter our 41st year and move forward as an organisation.”

The WJA represents water jetting contractors, equipment manufacturers, hire specialists and training providers. It is the UK’s largest provider of water jetting training, accredited by City & Guilds.

Industrial sectors water jetting is used in include: construction and structural maintenance; oil, gas and petrochemicals; marine maintenance; drainage and water utilities; manufacturing; and energy generation.

Hydroblast delivers a full range of water jetting services, including pipe and tank cleaning, surface preparation, refractory removal, material cutting and hydrodemolition. It also provides water jetting training and consultancy.

Ross McDonald said: “The water jetting industry has developed rapidly in recent years. The technology is proven and powerful, and includes new robotic water jetting systems that have greatly enhanced capability and safety.

“We want to maintain this momentum by encouraging the brightest and best young people into our industry. We need to show them they can develop an excellent career in water jetting.”

He said: “There is more than enough that is interesting and challenging in this industry to keep the most technically-minded person happy and fulfilled.

“Every day and every project teaches you something new. The challenge is to select right the pump, jetting equipment and accessories and combine pressure and flow rates ways that complete a task in the safest, most productive and most sustainable way.

“We consider the parameters placed on us by our client’s system specifications, the varying condition of legacy components we’re working on and the site conditions during the project. This all takes expertise and experience.

“Unit costs of hydrodemolition are higher than traditional removal methods, such as labourers with hammers and chisels. But those costs are outweighed greatly by productivity gains and the reduced risk of damage to pipework and other structures, as well as reduction in hand and arm vibration risks. It makes hydrodemolition the obvious choice.”

He is keen that the WJA constantly moves forward. “All industries are working hard to encourage the right people to join them, to ensure skills are maintained, passed on and developed in line with the needs of businesses and their customers,” he said.

“Water jetting is no different. I am confident we can provide young recruits with very rewarding careers.”

For more information on the Water Jetting Association, visit: www.waterjetting.org.uk