By offering a wide choice of materials and heat treatments for rolling bearings, performance and operating life can be optimised, even for the most demanding industrial applications, says Dr Steve Lacey, Engineering Manager at Schaeffler UK.

By offering a wide choice of materials and heat treatments for rolling bearings, performance and operating life can be optimised, even for the most demanding industrial applications, says Dr Steve Lacey, Engineering Manager at Schaeffler UK.

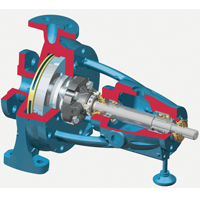

In recent years, there has been a significant increase in the demand for rolling bearings that, even under extreme operating conditions – including lubricant starvation, highly corrosive or high temperature environments – still provide a long operating life and optimum performance.

But selecting a suitable material or heat treatment process for rolling bearings often requires expert advice and guidance, normally from the manufacturer of the bearings. Selection depends on the application itself and the specific environment in which the bearings will operate. This means a number of factors require careful consideration, such as the mechanical, chemical and thermal requirements placed on the bearings, as well as lubrication conditions, particularly if the application requires dry running bearings.

Spherical roller bearings from Schaeffler now even more durable

Spherical roller bearings from Schaeffler now even more durable

Bearings are circular, much like the economy they are used in. As more customers avoid disposing of bearings needlessly, Chris Johnson, managing director of bearing re-lubricator SMB Bearings, explains the sudden surge in popularity of reusing and recycling ball bearings through relubrication.

Bearings are circular, much like the economy they are used in. As more customers avoid disposing of bearings needlessly, Chris Johnson, managing director of bearing re-lubricator SMB Bearings, explains the sudden surge in popularity of reusing and recycling ball bearings through relubrication.  The reliability of most rotating equipment is almost inevitably linked directly to bearing life, and it is estimated bearing failure is responsible for almost 21% of these equipment failures (Bloch, 2011).

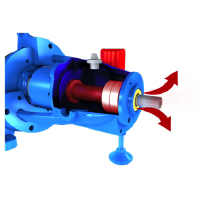

The reliability of most rotating equipment is almost inevitably linked directly to bearing life, and it is estimated bearing failure is responsible for almost 21% of these equipment failures (Bloch, 2011).  Save your bearings with LabTecta®66, which can reduce bearing oil contamination from 83% to 0.0003%.

Save your bearings with LabTecta®66, which can reduce bearing oil contamination from 83% to 0.0003%. By offering a wide choice of materials and heat treatments for rolling bearings, performance and operating life can be optimised, even for the most demanding industrial applications, says Dr Steve Lacey, Engineering Manager at Schaeffler UK.

By offering a wide choice of materials and heat treatments for rolling bearings, performance and operating life can be optimised, even for the most demanding industrial applications, says Dr Steve Lacey, Engineering Manager at Schaeffler UK.