To maximise the life expectancy of your bearings, you need to ensure the correct models are used, and that they are correctly fitted, lubricated and maintained; failure to do so may result in early bearing failure. Here, with SKF, we identify the most common causes of bearing failure, along with the symptoms to look out for and tips on how you can prevent premature failure.

Contamination

One of the most common causes of premature bearing failure is contamination, such as airborne dust or dirt. Contamination can occur during improper storage and handling prior to or during mounting, as well as during operation, so store bearings in their packaging in a clean environment.

The choice of bearings for heavily contaminated environments, or where contamination of the process is also an issue, is key. In these instances, focus on the design of the housing and the seals/sealing system. Bearing seals will prevent contaminants from entering the bearing unit, whilst keeping lubricants from leaking out. Specialist sealing solutions have also been developed for very heavily contaminated environments, such as SKF’s Three-Barrier Solution which consists of a sealed spherical roller bearing, bearing housing with seals and a biodegradable grease to act as a contamination barrier.

Excessive Load

Failure of this sort can look similar to normal bearing fatigue with the main tell-tale signs including the deterioration of running surfaces of the inner ring, outer ring or rolling elements. To function in applications where heavy loads are the norm, you want a bearing that is both hard and tough. New heat treatment processes have made hardened steel suitable for use.

Also, consider both axial and radial loads when choosing your bearings. Bearings are available that accommodate both.

Overheating

One of the more obvious symptoms of overheating includes the discolouration of the rings, rolling elements and cages. Overheating results in a loss in hardness, reducing the bearing capacity and leading to premature failure.

Main causes of overheating include insufficient cooling, incorrect radial internal clearance or inadequate or too much lubrication. Overheating can also be caused by the bearing being overloaded. Where possible, consider installing adequate thermal controls and reassess the bearings being used are adequate to accommodate the application, lubricant, and load requirements.

Inadequate Lubricant

Up to 36% of bearings fail prematurely due to inadequate lubrication.

One of the main signs of lubricant failure begins with the discoloured (blue/brown) raceway and rolling elements. This will often be followed by excessive wear of rolling elements, ring and cages resulting in overheating. This type of failure is typically caused by excessive or too little of the correct lubrication, possible restricted lubricant flow and/or excessive temperatures. To combat this consider investing in a bearing that has built-in lubrication as part of its design.

Corrosion

Corrosion can result from exposing a bearing to a corrosive fluid or atmosphere, with symptoms including discolouration on raceways, cages and rolling elements. To ensure best practice, divert corrosive fluids away from any bearing area if possible and/or consider using a sealed or housed bearing. SKF for example can offer various corrosion resistant bearings, such as stainless steel or with special coatings along the housings made from polypropylene composites.

Misalignment

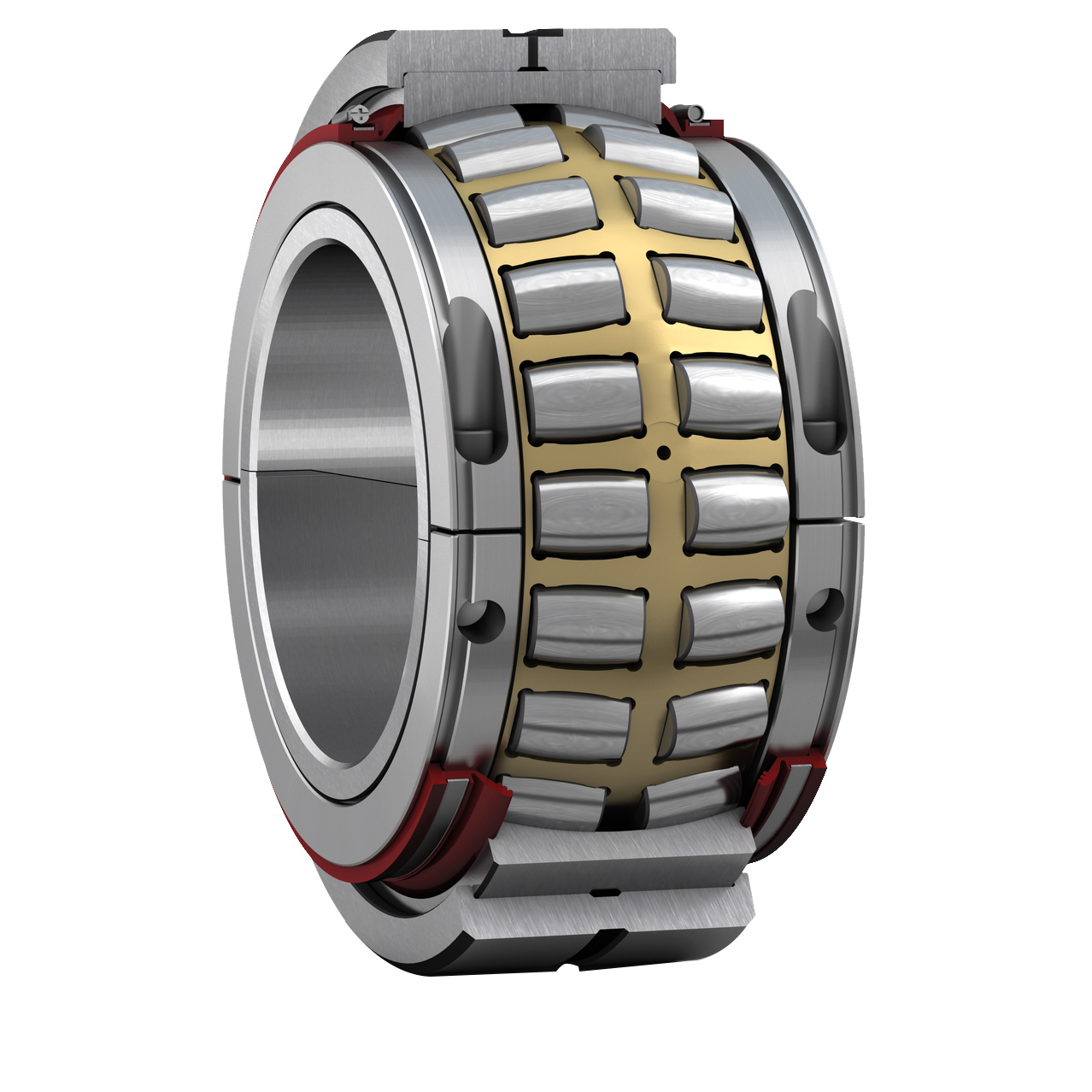

Misalignment can result in unnecessary forces being applied to machinery leading to increased wear and vibration causing premature bearing failure and costly machine downtime. Sometimes caused by a loose-fitting bearing, misalignment can be typically observed by its uneven running paths. Whilst it is important to have the bearings as accurately aligned as possible, there are several products that will accommodate some degree of misalignment: Spherical roller bearings, SKF CARB Toroidal roller bearings, self-aligning roller bearings, SKF Cooper bearing and housed bearing units.

Incorrect fitting

Approximately 16% of bearings fail prematurely due to damage caused by the incorrect mounting technique for the application and bearing type so correct fitting and removal of bearings is vital to achieve best performance. Firstly, it is important not to fit bearings to seatings which have been damaged by previous bearing failure. It is equally as important to ensure seatings are of the correct specification, as this is a common cause of bearing failure.

Rubix is Europe’s leading authorised bearings distributor.