The world of equipment maintenance changed dramatically during the second half of the 20th century and it continues to do so today.

The world of equipment maintenance changed dramatically during the second half of the 20th century and it continues to do so today.Several major influences have been responsible for driving these changes:

The world of equipment maintenance changed dramatically during the second half of the 20th century and it continues to do so today.

The world of equipment maintenance changed dramatically during the second half of the 20th century and it continues to do so today.The world of equipment maintenance changed dramatically during the second half of the 20th century and it continues to do so today.

Several major influences have been responsible for driving these changes:

Our new eBrochure comprehensively describes all of our products and services in a single slick page-turn document. The brochure can be viewed directly on our web site, downloaded for off-line viewing or ordered on CD-ROM. A PDF version is also available to download.

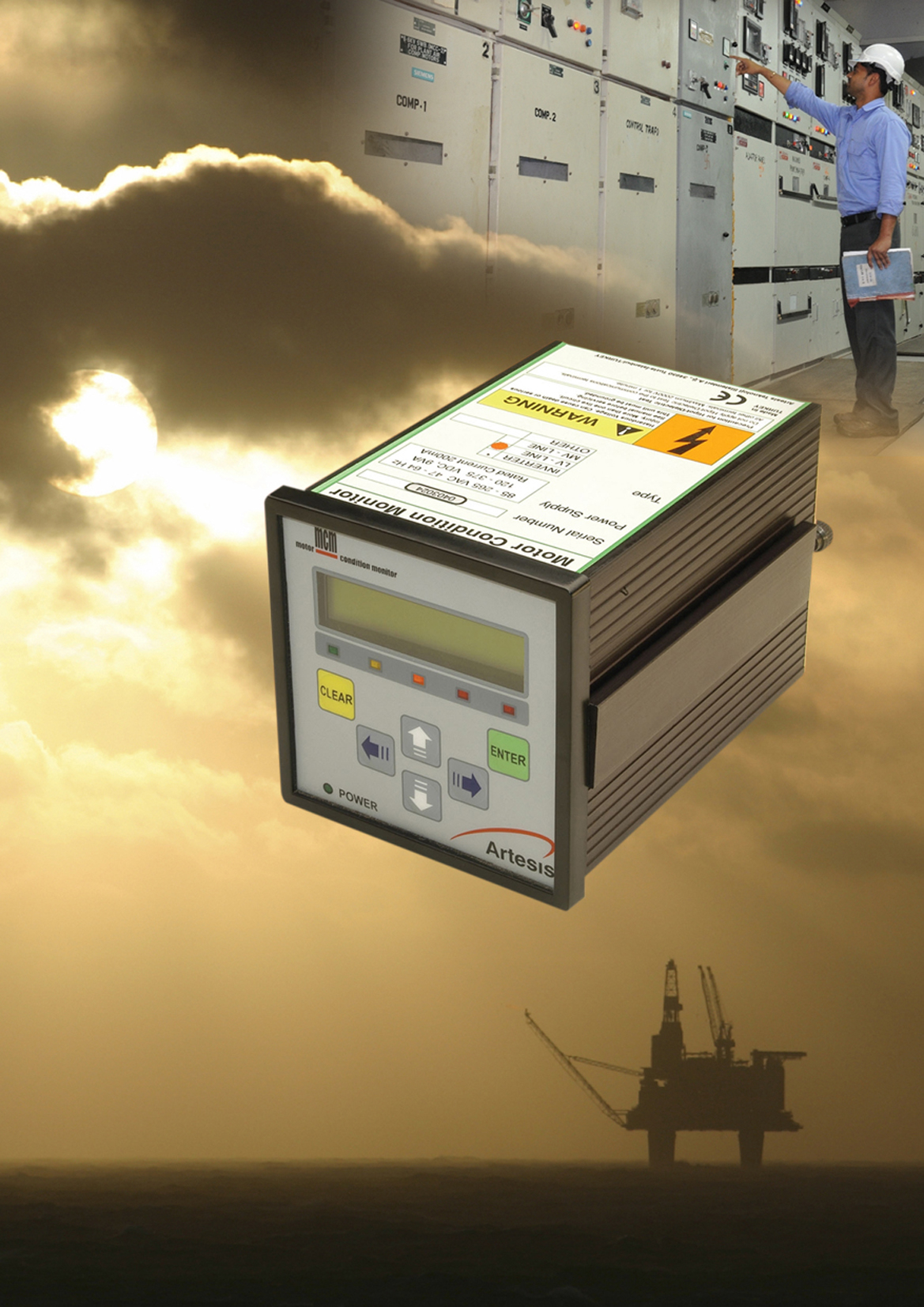

Our new eBrochure comprehensively describes all of our products and services in a single slick page-turn document. The brochure can be viewed directly on our web site, downloaded for off-line viewing or ordered on CD-ROM. A PDF version is also available to download. Artesis, leading supplier of intelligent predictive maintenance solutions, has secured a significant agreement to supply and install its market-leading Motor Condition Monitor (MCM) systems to all of the most critical escalators across 4 terminal buildings at Heathrow Airport. Reliability and minimum breakdown of passenger moving equipment is crucial to the successful operations at Heathrow and this deal secures Artesis as BAA’s leading supplier of condition monitoring solutions.

Artesis, leading supplier of intelligent predictive maintenance solutions, has secured a significant agreement to supply and install its market-leading Motor Condition Monitor (MCM) systems to all of the most critical escalators across 4 terminal buildings at Heathrow Airport. Reliability and minimum breakdown of passenger moving equipment is crucial to the successful operations at Heathrow and this deal secures Artesis as BAA’s leading supplier of condition monitoring solutions. Why Monitor?

Why Monitor?

More than 40 years of experience and close cooperation with our users worldwide enable SPM to present a revolutionary innovation for pro-active maintenance.

Leonova™ Infinity marks a decisive advance in machine condition monitoring

SPM has the organisation and the know-how to increase the availability and profitability of your production equipment. Knowing that your situation is special, we gave Leonova Infinity a comprehensive range of functions and developed a new system of financing condition monitoring.

Remove moisture and particles before entry to the system.Moisture and particle accumulation are major factors of oil contamination in industrial equipment. Neglected, these detriments restrict equipment efficiency, causing machine downtime and significant expense in replacement oil, parts and repair labour. Des-Case hygroscopic breathers incorporate a proven, field tested design.

Remove moisture and particles before entry to the system.Moisture and particle accumulation are major factors of oil contamination in industrial equipment. Neglected, these detriments restrict equipment efficiency, causing machine downtime and significant expense in replacement oil, parts and repair labour. Des-Case hygroscopic breathers incorporate a proven, field tested design. Dorchester based, Tritex NDT have developed a new range of triple echo ultrasonic thickness gauges for measuring metal thickness to check for corrosion on pipelines, storage tanks and other industrial applications where corrosion occurs. The new Tritex Multigauges have been designed for robustness, simplicity of use and most importantly, accuracy.

Dorchester based, Tritex NDT have developed a new range of triple echo ultrasonic thickness gauges for measuring metal thickness to check for corrosion on pipelines, storage tanks and other industrial applications where corrosion occurs. The new Tritex Multigauges have been designed for robustness, simplicity of use and most importantly, accuracy.  Artesis, a leading supplier of intelligent predictive maintenance solutions, is pushing the boundaries of machine monitoring technology with its next generation solution. Delivering a range of powerful new functionality the Artesis MCM (Motor Condition Monitor) system now includes wireless technology for deployment in remote and inaccessible locations; fully automated condition assessment reports for even faster diagnostics; and the ability for engineers to easily and quickly customise the application for wider enterprise use.

Artesis, a leading supplier of intelligent predictive maintenance solutions, is pushing the boundaries of machine monitoring technology with its next generation solution. Delivering a range of powerful new functionality the Artesis MCM (Motor Condition Monitor) system now includes wireless technology for deployment in remote and inaccessible locations; fully automated condition assessment reports for even faster diagnostics; and the ability for engineers to easily and quickly customise the application for wider enterprise use. In about 50% of organizations spare parts and materials stores reports to the maintenance organization. In about 50 % of organizations spare parts and materials stores is part of the purchasing function.

In about 50% of organizations spare parts and materials stores reports to the maintenance organization. In about 50 % of organizations spare parts and materials stores is part of the purchasing function. Hansford Sensors Ltd. now offer a range of submersible vibration sensors, which has been specifically designed for operation in partial or complete immersion in water, making them ideal for the monitoring of pumps in a maintenance role.

Hansford Sensors Ltd. now offer a range of submersible vibration sensors, which has been specifically designed for operation in partial or complete immersion in water, making them ideal for the monitoring of pumps in a maintenance role.This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE