Condition Based Maintenance (CBM), using tools such as vibration analysis, thermal and ultrasonic imaging, and oil analysis, is now clearly recognised as being the key to running an effective maintenance program. By comparison, planned periodic maintenance, or worse still breakdown maintenance, are not only unnecessarily expensive and unreliable, but potentially fraught with danger!

But why is CBM the answer? Firstly, when using CBM tools, service and maintenance personnel bring another very valuable asset to the job – they use their eyes and ears! For example, by spotting things like oil leaks or worn drive belts, breakdowns can be avoided through timely intervention.

To assist with this process, software tools are now available to lead even a novice user through the process of making inspections to produce clear and fully documented reports, which can automatically generate alerts and workflow tasks.

Additionally, CBM brings with it the ability to implement Proactive Maintenance. This is essentially the process of “closing the loop” by identifying the root cause of a fault and correcting it. For example, vibration analysis might indicate a badly worn bearing that has failed after only a few months, well within the manufacturer’s specified MTBF. Without identifying the root cause of the premature failure, the bearing might simply be changed only to soon wear out again.

It is generally accepted that the three main causes of premature bearing failure in rotating equipment are:

- Out of balance

- Misalignment

- Lack of lubrication

Fortunately, thanks to modern technology, all of these conditions can be detected very easily using extremely affordable, simple to use handheld vibration analysers.

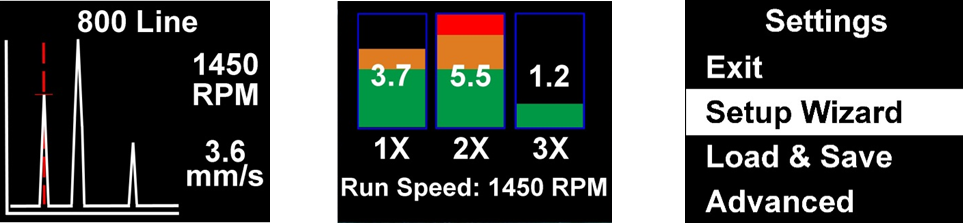

Out of balance for example, shows up as a large amplitude vibration at the running speed (1X) of the machine.

Misalignment on the other hand generally shows up as an additional large vibration at twice the running speed (2X).

Lack of lubrication will result in high frequency vibration (bearing noise) that is not necessarily audible to the human ear but can easily be detected by a vibration analyser.

These days, once diagnosed, all these faults can easily be remedied in-house using affordable easy-to-use tools such as in-situ rotor balancers, laser alignment systems or even a simple grease gun!

Not so long ago CBM tools used to be considered expensive and difficult to use. But thanks to modern technology, these tools are now not only extremely affordable; they are also simple to use.

The TPI 9070 (pictured) is a simple to use, incredibly low-cost vibration analyser that records, analyses and displays vibration at the push of a button. The unit displays colour coded alarm levels based on internationally agreed (ISO) vibration values and bearing condition. It also incorporates a fully zoomable vibration frequency spectrum (FFT) display with cursor, and diagnoses out of balance, misalignment, looseness and bearing faults.

TPI manufactures a complete range of low cost, high performance, easy to use vibration analysis tools for maintenance engineers. All are incredibly easy to use, from the simple one-button-to-press, TPI 9070 to top-of-the-range CBM units that include machine balancing.

The TPI 9085 (with the ATEX/IECEx/USA/Canada Zone 0 certified TPI 9085-Ex version also available) is the latest in the line of easy-to-use high specification maintenance products. The TPI 9085 offers high level functionality and capability, including instantaneous bearing temperature measurement, at extremely low cost. The TPI 9085 can automatically download machine routes (as simple lists) that can be followed by even the lowest skilled operative to collect and store vibration and temperature readings for automatic upload to the included, free-to-use, C-Trend II trending software. This powerful but highly intuitive windows-based software, with its ability to automatically generate reports and email alerts, allows faults to be identified well ahead of when they start to become a problem that could result in unexpected breakdowns.

For more information, please contact TPI Europe on +44 1293 530196 or www.tpieurope.com or email This email address is being protected from spambots. You need JavaScript enabled to view it.