Monition’s reliability service has convinced many organisations that condition monitoring is the most viable method to maintain machinery uptime, and has illustrated that even machinery repairs and component renewals can be no guarantee for troublefree running.

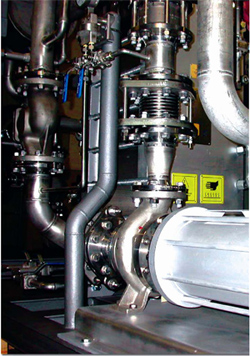

Monition’s reliability service has convinced many organisations that condition monitoring is the most viable method to maintain machinery uptime, and has illustrated that even machinery repairs and component renewals can be no guarantee for troublefree running.Monition’s Multi-Technology Condition Monitoring at a food processing plant identified a loose rotor bar on a critical watercooling pump motor. The engineering manager scheduled an immediate

replacement, expecting the problem to be cured.

However, immediately following the work, Monition discovered that the unit was still at risk.

Monitoring indicated that the coupling had been incorrectly refitted and was being

subjected to accelerated wear.

Realignment work was promptly undertaken, but further monitoring again revealed problems. The pump support bearing had been damaged during the realignment process and now required urgent attention.

Monition assisted the client to prevent a plant breakdown on 3 occasions and also highlighted an important need to troubleshoot repair processes.

Multi-Technology Condition Monitoring

Monition’s multi-technology, condition monitoring and plant reliability service provides a PROVEN, 99% predictability of failure-rate in monitored plant items after 12 months – as measured against industrially-recognised, 6sigma KPIs.

100% Convinced?

Contact Monition and ask us to prove how our Multi-Technology Service will make the

difference in YOUR operations

T: 01909 722000

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

W: www.monition.com