To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group. As the world leader in glass bead impact technology, Potters is continually developing and refining its manufacturing procedures to ensure consistently high quality glass spheres, which are tested to conform to every market specification.

The company recently installed a new bagging line at its Barnsley production facility to handle increased volumes and as a result the air consumption increased from 400 cubic feet per minute (CFM) to 800 CFM. To meet this need, and to maximise efficiency, a new compressed air solution was required.

The world's biggest printing plant is operated by News International, publishers of The Times, Sunday Times, News of the World and the Sun newspapers, and owned by media magnate Rupert Murdoch.

The world's biggest printing plant is operated by News International, publishers of The Times, Sunday Times, News of the World and the Sun newspapers, and owned by media magnate Rupert Murdoch. BEKO Technologies have recently solved a major headache for Imperial Tobacco in Nottingham, England.The problem was caused when insurance inspectors condemned two old 10” flanged filters in the main plant room, the filters were in excess of 15 years old and suffered from significant corrosion.

BEKO Technologies have recently solved a major headache for Imperial Tobacco in Nottingham, England.The problem was caused when insurance inspectors condemned two old 10” flanged filters in the main plant room, the filters were in excess of 15 years old and suffered from significant corrosion.  PMJ International, the one stop shop for all your compressed air needs have two special offers for September for EMS readers. Any timed automatic drain ¼” ⅜” ½” port size in any voltage 24v 110v 240V only £23.50 each! (Please quote E09 when ordering). All orders over £300.00 will be delivered CARRIAGE FREE.

PMJ International, the one stop shop for all your compressed air needs have two special offers for September for EMS readers. Any timed automatic drain ¼” ⅜” ½” port size in any voltage 24v 110v 240V only £23.50 each! (Please quote E09 when ordering). All orders over £300.00 will be delivered CARRIAGE FREE. Profitability is everything in a competitive environment. BEKO Technologies, the market leaders in compressed air technology, boast a comprehensive program of systems designed to save energy and improve efficiency in the application of compressed air.

Profitability is everything in a competitive environment. BEKO Technologies, the market leaders in compressed air technology, boast a comprehensive program of systems designed to save energy and improve efficiency in the application of compressed air. The DRYPOINT® M PLUS membrane dryers with an integrated nanofilter made by BEKO TECHNOLOGIES, Neuss, Germany, have proven themselves particularly useful when employed downstream of compressors (in satu-rated compressed air which is warmer than the ambient air).

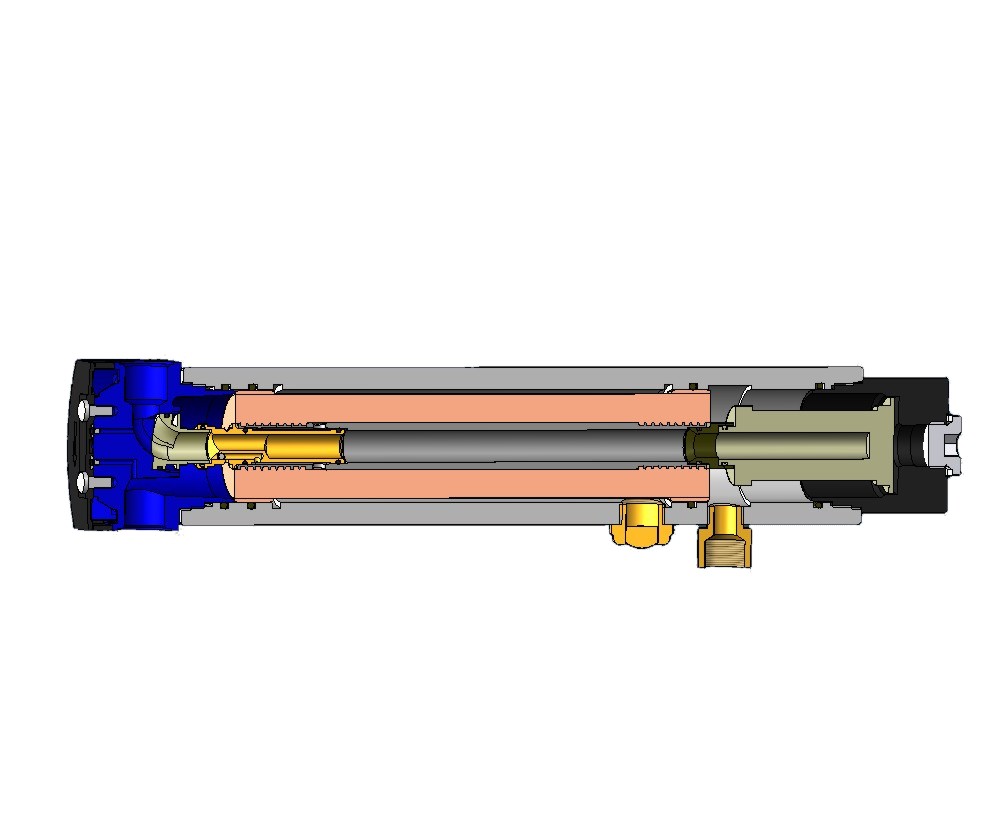

The DRYPOINT® M PLUS membrane dryers with an integrated nanofilter made by BEKO TECHNOLOGIES, Neuss, Germany, have proven themselves particularly useful when employed downstream of compressors (in satu-rated compressed air which is warmer than the ambient air).  To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group.

To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group.  To ensure customers can immediately comply with current regulations, Airchannel, the UK’s leading independent compressed air specialist, is providing an integrated Written Scheme of Examination (WSE) as part of its complete service.

To ensure customers can immediately comply with current regulations, Airchannel, the UK’s leading independent compressed air specialist, is providing an integrated Written Scheme of Examination (WSE) as part of its complete service. Michell Instruments’ MDM300 advanced dew-point hygrometer can save engineers weeks of waiting time each year.

Michell Instruments’ MDM300 advanced dew-point hygrometer can save engineers weeks of waiting time each year. To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group. As the world leader in glass bead impact technology, Potters is continually developing and refining its manufacturing procedures to ensure consistently high quality glass spheres, which are tested to conform to every market specification.

To meet new requirements, Airchannel has installed a new CompAir L132 SR Rotary screw compressor at leading technical glassware producer, Potters Ballotini, part of the global Potters Industries group. As the world leader in glass bead impact technology, Potters is continually developing and refining its manufacturing procedures to ensure consistently high quality glass spheres, which are tested to conform to every market specification.