Birmingham-based Armac Martin, a pioneer in design-led luxury brass hardware and accessories, relies heavily on compressed air for its CNC machining requirements. However, the company’s existing system was constantly operating at full capacity, leading to unnecessary energy expenditure. By collaborating with FPS Compressors and its preferred local distributor Compressed Air Systems UK - Birmingham, Armac Martin adopted a new system capable of variable compressed air supply. The project led to an impressive 46% reduction in energy consumption compared with the company’s previous compressor.

Founded in 1929 as a local brass foundry, Armac Martin is today a fourth-generation family business with a global reputation for exceptional design and craftsmanship. Compressed air is critical to the successful operation of the company’s modern CNC machining centres. At the same time, like all manufacturers, Armac Martin is driving to make its operations more sustainable. The company has a strategy to achieve net zero by 2041, making the significant energy drain of its compressed air system a cause of major concern.

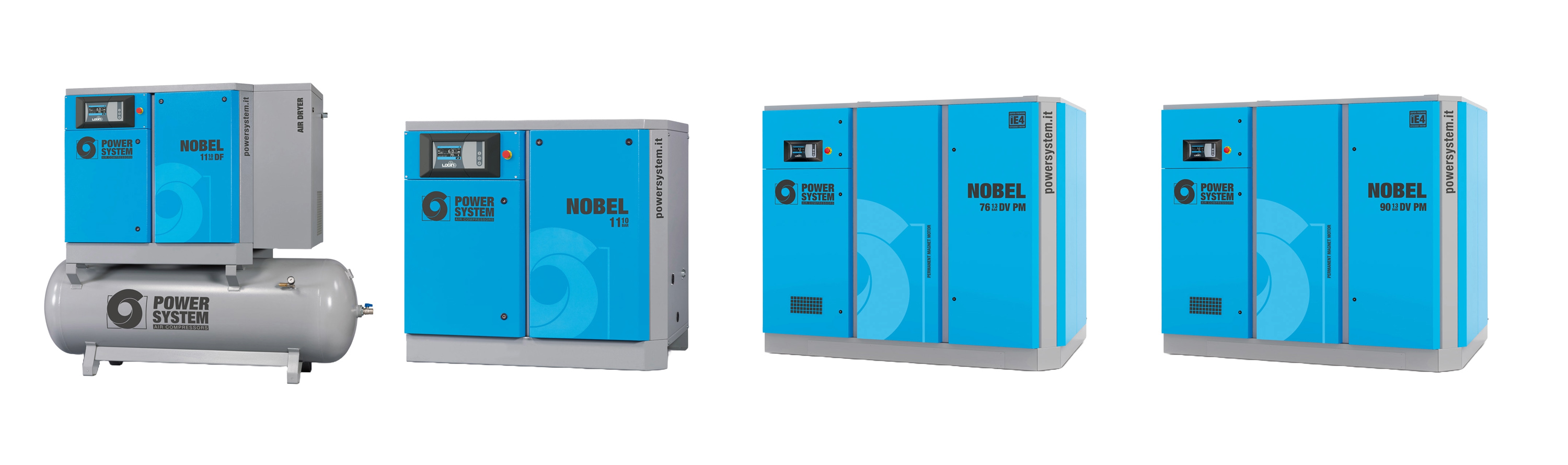

Collaborating with FPS Compressors and Compressed Air Systems UK - Birmingham, Armac Martin opted for a new system capable of variable compressed air supply, identified through data logging and energy audit exercises. Monitoring of the system took place using state-of-the-art instruments over several weeks. FPS Compressors and Compressed Air Systems UK - Birmingham explained both the data and the recommend solution to Armac Martin’s management team. Notably, the transition to the new compressed air system, which features a NOBEL 18.508 DVF PM variable-speed screw air compressor from FPS at its core, was seamless and without downtime. Comprehensive training ensured proficiency in operation.

With the NOBEL 18.508 DV FPM, compressed air aligns to system requirements by regulating the speed of the electric IE4 permanent magnet motor, which can range from 15-100% of the maximum speed. Notably, the direct-drive system means zero energy losses, whereas standard drive belts may incur losses of 4-11% as the energy transfers from the motor to the compressor. Excellent and precise pressure control extends from 6 to 13 bar, while accurate and optimised cooling of the compressor arrives courtesy of efficient, powerful and quiet radial fans.

By partnering with industry experts and embracing innovative technologies, Armac Martin is seeing a remarkable 46% reduction in compressor energy consumption, translating to an impressive £23,637 in annual savings. The return-on-investment [ROI] for this sustainable initiative was achieved in just 14 months.

“The use of compressed air represents a large chunk of electricity costs at machine shops such as Armac Martin, just like it does at any manufacturing plant, food production facility or packaging plant,” says Nick Poole, Managing Director at FPS Air Compressors. “To make gains, users of compressed air must get smart about specifying the optimal technology, notably the compressor. Armac Martin is a great example of what this strategy can deliver. While the company’s previous compressed air system ran constantly at full capacity, the new solution reduces power requirements by only meeting actual demand. The result? Significant improvements in energy efficiency without any compromise in manufacturing performance.”

For additional information on this case study please visit:

www.fps-compressors.co.uk/fps-case-study-armac-martin.html

Further information is available from:

FPS Air Compressors Ltd, Unit 5, Tower Estate, Warpsgrove Lane, Chalgrove Oxfordshire OX44 7XZ

Telephone: 01865 892 620 e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.