Condition Monitoring (CM) gives its full value when it is used to drive Condition-Based Maintenance (CBM) or at the very least is used to plan corrective work before machine failure occurs.

However, just having an overall measurement of machine condition, such as an overall vibration level reading, doesn’t tell you enough to do this. What you need to know to plan efficient corrective work before machine failure is:

What is the nature of the fault that is developing?

How rapidly is it developing?

What should I do about it?

When will I need to intervene?

Faraday Predictive provide all of this information without needing to cover your machine with sensors – in fact without fitting any sensors on the machine itself, because the Faraday Predictive system effectively turns your electric motors into sensors of machine condition.

Faraday Predictive use what are known as MBVI – “Model-Based Voltage and Current” systems.

By simply measuring the voltage and current drawn by the motor, the Faraday Predictive system provides an astonishing amount of information, including:

What phenomena (eg faults) are detectable in this machine?

How severe are each of those phenomena or faults?

What does the developing trend for each fault look like?

When is it predicted to reach a level that will need maintenance intervention?

What is the recommended corrective work?

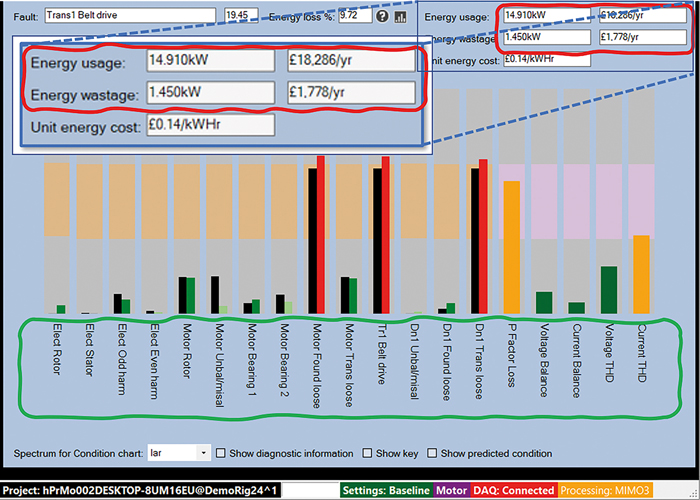

An example of the sort of phenomena that can be detected in any one machine is shown outlined in green on this typical screen output shown here:

The Faraday Predictive system can identify around 40 different phenomena, including unbalance, misalignment, bearing problems or belt drive problems in addition to a dozen measured parameters that can also indicate developing faults, such as overall levels of voltage and current, active power levels, phase imbalance, voltage distortion and current distortion – but will only indicate those that are relevant to this particular machine. The system itself identifies which phenomena are relevant automatically.

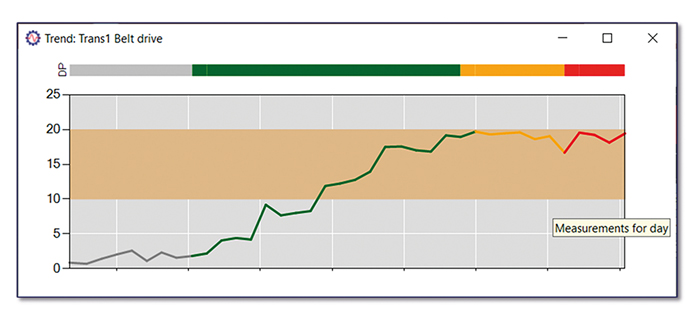

For any one of these phenomena, the system can plot a trend graph of the severity developing through time – for example here is the plot for a belt drive problem:

Belt drive faults are identified from signals at the characteristic frequency of the belt – which the system calculates for itself as the time for the belt to go around both pulleys and back to the starting point, based on three simple parameters that you enter into the system – the diameters of the two pulleys and the centre-to-centre distance between them. Other faults are identified in a similar manner based on their specific characteristic frequencies. More details of this can be found here:

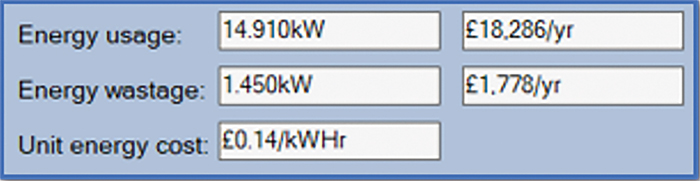

An added feature of the Faraday Predictive system is that, being based on measurements of voltage and current, it can not only calculate the energy being used by the machine, it can also quantify the amount being wasted by each fault. It also translates these kWH figures into real money – showing you how much each fault is costing you during the course of a year, allowing cost justification of maintenance interventions, even before reaching the risk of actual machine failure. It surprises many engineers to see just how much a modest sized motor costs in electricity to run each year – here a 15kW / 20HP motor can be seen to be costing over £18,000 / year – of which nearly 10% is being wasted by faults:

So in summary, the Faraday Predictive condition monitoring system not only tells you about developing faults in your machines, it also tells you what to do, when to do it, and the cost benefit of it in electricity savings that will result. Not bad for a condition monitoring system!

For more information about Faraday Predictive visit:

www.faradaypredictive.com