Motor Current Monitoring is increasingly being understood as just another form of Vibration Analysis – but one that can also cover electrical faults and energy consumption.

The purpose of Condition Monitoring is to detect developing faults before the machine fails catastrophically, avoiding unexpected breakdowns and allowing maintenance work to be planned efficiently at a time of minimal disruption to operations.

Many techniques are available – and should be selected to detect the type of faults relevant to the particular machine, so there is no single universal panacea. Techniques that can detect a wider range of faults can obviously be applied more widely – and one of those with the widest range is the Model-Based Voltage and Current (MBVI) technique, as used by Faraday Predictive.

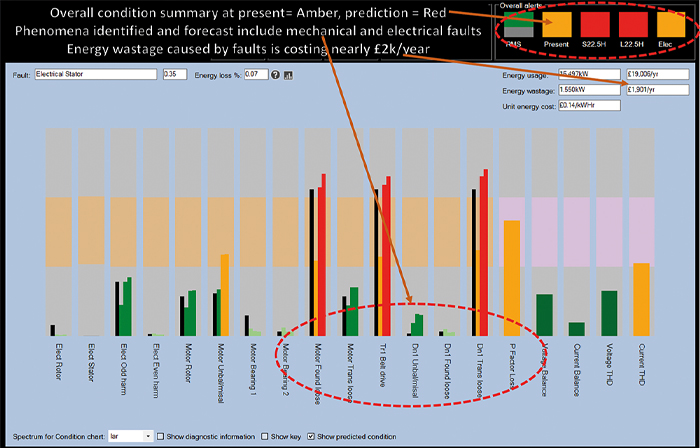

This uses the motor as a sensor and by clever automated analysis of the relationship between voltage and current, and how this changes over time, it can automatically detect, discriminate and diagnose an astonishingly wide range of phenomena, including mechanical, electrical and operating faults. It also measures energy consumption, and identifies how much energy is being wasted by each developing fault, allowing users to cost-justify precision maintenance to eliminate the fault on the basis of electricity cost saving.

The net result is an automated output of the current and predicted state of the machine as a whole, the energy cost and wastage, and an assessment of the current and predicted state of each developing fault – which can directly feed maintenance and operations planning. See below – the display of phenomena in this particular machine includes both electrical and mechanical faults.

So how does motor current and voltage predict specific mechanical failures in this way? Motor current is very sensitive to the load on the motor – increased load results in increased current – so the current is effectively an indication of the torque required to drive the machine. Because developing faults cause subtle variations in this torque, they create subtle variations in motor current, at the characteristic frequency of the fault in question. The motor is therefore a sensor of torsional vibrations, and MBVI systems are effectively just another form of vibration monitoring, using torsional vibration, rather than the radial or axial vibration that is normally measured by accelerometers used by conventional Vibration Monitoring. But of course, in addition to measuring the normal mechanical parameters, MBVI systems also provide information on electrical faults and energy consumption at the same time.

These diagnostic conclusions are all based on analysis of voltage and current waveforms, which is at the heart of Faraday Predictive’s Model-Based Voltage and Current Analysis. This is a sophisticated process, for example the apparent shape of these waveforms can look quite different depending on the sample rate, as shown here for the Voltage output from an inverter, sampled at 1kS/s, 5kS/s and 25kS/s.

The pictures above show how the resolution of the time waveform picture increases with higher sample rates. But most of the analysis of the waveform is done in the Frequency Domain, by converting the time waveform from the time domain into a spectrum by a process of Fast Fourier Transform (FFT):

The Faraday Predictive systems do this interpretation automatically, providing you with the maximum benefit without you needing to “get your hands dirty”. The system not only does all the time waveform and spectral computation for you automatically, it also identifies each individual fault and trends it through time, and predicts the time at which each fault will require maintenance, to give you actionable advice without you needing to get bogged down in all this analysis. But it also makes it all visible to you at the touch of a button, so you can see and understand why the system has reached these conclusions and recommendations if you wish. The best of both worlds!

For more information visit:

https://www.faradaypredictive.com/technical-education/diagnostic-outputs/sample-rate-sample-length-resolution-and-fmax/

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. Call: 0333 772 0748