Severe corrosion kept at bay with hard-wearing epoxy material

Severe corrosion kept at bay with hard-wearing epoxy material

The pipework at a coal fired power station in the UK was experiencing severe corrosion issues caused by abrasive limestone slurry material. Due to the extent of the damage, the average lifetime of the pipes had been dramatically reduced to less than six months before the pipe spool pieces had to be completely replaced. The station required a repair solution that would provide extremely robust protection against the abrasive material and therefore significantly increase the working life of the equipment.

The pipework at a coal fired power station in the UK was experiencing severe corrosion issues caused by abrasive limestone slurry material. Due to the extent of the damage, the average lifetime of the pipes had been dramatically reduced to less than six months before the pipe spool pieces had to be completely replaced. The station required a repair solution that would provide extremely robust protection against the abrasive material and therefore significantly increase the working life of the equipment.

Background Information

The pipes are situated in the FGD (Flue Gas Desulphurisation) Plant part of the power station, which operates the removal of harmful chemicals from the exhaust gases, specifically Sulphur Dioxide (SO2). The gasses are passed through a limestone slurry which ‘scrubs’ the SO2 from the gasses emitted. A direct product of this process is that Calcium Sulphate (CaSO3) and Carbon Dioxide (CO2) are created. The limestone slurry, now containing highly abrasive limestone material and corrosive Calcium Sulphate is then pumped away for further treatment. It is at this step, where the pipework is subjected to the highly erosive and corrosive media.

Application Specification

As the applicators, Pump Supply & Repair Group, had already carried out similar applications using Belzona polymeric materials for the same client, resulting in a 50% increase in the usable life of the pipework, the same repair system and application was specified.

Belzona 1812 (Ceramic Carbide) was chosen to repair and protect the existing pipework, consisting of 12 pipe spools. This composite material combines extremely hard, closely packed abrasion resistant ceramic aggregates in a polymeric binder, making it ideal for the maintenance of substrates damaged by particle abrasion. This durable technology will fortify the 4” pipe interiors, ensuring they will remain protected when subjected to the abrasive limestone slurry.

Quick and Simple Application Method

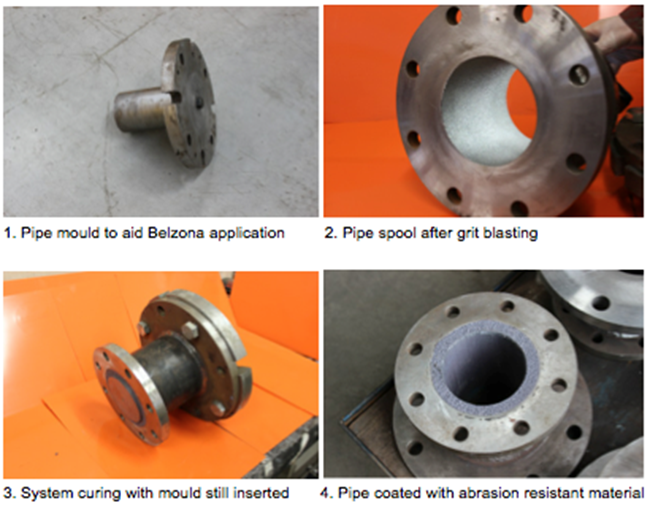

Firstly, the substrate was grit blasted to remove all possible contaminants and also to achieve Surface Cleanliness Standard Sa2½ with a 75µ profile. Following this, the pipes were then salt tested to confirm acceptable levels of contamination.

To reduce the application time and to increase accuracy, a flanged mould with a machined insert was manufactured. This mould was then bolted onto the pipes prior to coating, allowing the technician to completely fill all spaces with Belzona 1812 uniformly whilst ensuring the internal dimensions were kept to specification. Finally, the pipes were machined true using a diamond tipped tool.

Cold-Curing Technology Reduces Downtime

“Due to its molecular structure making it extremely resistant to both erosion and corrosion, the Belzona material was able to not only repair the damaged equipment, but also significantly increase its life expectancy too. This will save the power station a considerable amount of financial expenditure as they will no longer require the excessive amount of downtime needed for the removal and replacement of the pipework.” Steve Smith, Quotation Engineer, Pump Supply & Repair Group.

Belzona Polymerics Limited

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.belzona.com