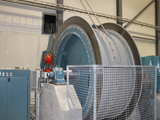

At the Renström mine in northern Sweden, Swedish mining company Boliden monitors the mechanical condition of the multi-rope friction hoist using SPM HD and vibration analysis.

At the Renström mine in northern Sweden, Swedish mining company Boliden monitors the mechanical condition of the multi-rope friction hoist using SPM HD and vibration analysis.

In 2012, Boliden tested a number of condition monitoring systems on an autogenous mill at its mine in Garpenberg, Sweden. The tests led to a strategic decision to implement condition monitoring solutions from SPM for mining equipment within Boliden. As a result of this decision, the Intellinova online system was installed on the mine hoist in the Renström mine last year. Mats Johansson, Maintenance Manager, about the investment: "The main hoist is critical equipment (A-rated) for us and the heart of our business. If the hoist malfunctions, production more or less comes to a halt. On this type of equipment, we need good control and that makes online monitoring necessary."

The hoist is a process critical application used in underground mines for transporting materials or personnel. This case study describes the friction hoist application in the Renström mine; currently Sweden’s deepest mine at 1340 m. Using the SPM HD measuring technique and vibration analysis, the online system monitors hoist bearings and gears to ensure around the clock operation and provide automatic alarms.

The combination of vibration and shock pulse technologies is optimal for this type of application. Shock pulse transducers pick up bearing related signals very clearly, yielding crisp and easily interpreted readings, while vibration transducers pick up gear mesh frequencies in the gearbox, unbalance in the drum and other low frequency vibrations.