As an integral part in its aim to educate and support technicians in best practice for maintenance and troubleshooting across a wide range of industrial processes, Fluke has developed a wealth of background information relating to preventive maintenance and troubleshooting motors and drives which can be found at https://www.fluke.com/en-gb/learn/best-practices/motors-and-drives

The user is immediately offered the opportunity to contact and speak to a Fluke motor drive specialist for advice on optimum approaches and the ideal tools.

With the launch of the SICK AHS36 (singleturn) and AHM36 (multiturn) IO-Link absolute encoders, SICK has opened up wide-ranging new possibilities to integrate rotary motion sensing into the ‘smart’ sensor configurations of automated machinery.

With the launch of the SICK AHS36 (singleturn) and AHM36 (multiturn) IO-Link absolute encoders, SICK has opened up wide-ranging new possibilities to integrate rotary motion sensing into the ‘smart’ sensor configurations of automated machinery.The SICK AHS36 and AHM36 36mm IO-Link encoders are SICK’s first range of absolute encoders with IO-Link. The SICK AHS/AHM36 IO-Link encoders achieve quick, easy and economical higher-level fieldbus integration via an IO-Link Master. Developments to advanced IO-Link versions of the encoder will also enable processing of Smart Tasks within the encoder itself.

Analyses electrical and mechanical performance on operational motors without mechanical sensors to extend system lifespan

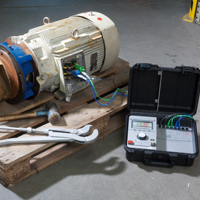

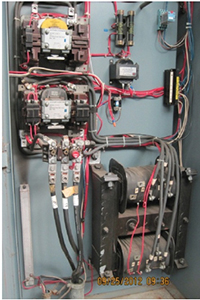

Analyses electrical and mechanical performance on operational motors without mechanical sensors to extend system lifespan The 2016 show will feature a major presentation of advanced Electric Motor Testing and Condition Monitoring Instruments from Whitelegg Machines.

The 2016 show will feature a major presentation of advanced Electric Motor Testing and Condition Monitoring Instruments from Whitelegg Machines. Some of your process motors could be close to failure with others running inefficiently.

Some of your process motors could be close to failure with others running inefficiently.  Starting air compressors are only a small part of a new ship, but one that is all the more important during operation. For this reason, it is necessary that their most recent specifications are already available to shipyards when ordering. Otherwise, operators may face some disadvantages: inadequate operation, high maintenance costs, low machine availability and many more.

Starting air compressors are only a small part of a new ship, but one that is all the more important during operation. For this reason, it is necessary that their most recent specifications are already available to shipyards when ordering. Otherwise, operators may face some disadvantages: inadequate operation, high maintenance costs, low machine availability and many more.  by Dave Olinger and Ernesto Wiedenbrug, Ph.D.

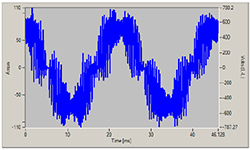

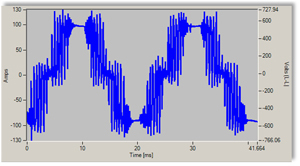

by Dave Olinger and Ernesto Wiedenbrug, Ph.D.  Ernesto Wiedenbrug, Ph.D.

Ernesto Wiedenbrug, Ph.D.  by Ernesto Wiedenbrug, Ph.D.

by Ernesto Wiedenbrug, Ph.D.  Ernesto Wiedenbrug, Ph.D., SM IEEE,

Ernesto Wiedenbrug, Ph.D., SM IEEE,  Ernesto J. Wiedenbrug, Ph.D., SM IEEE

Ernesto J. Wiedenbrug, Ph.D., SM IEEE