Carbon capture and storage (CCS) plays a vital role in mitigating greenhouse gas emissions and combating climate change. Since 2019, the global capacity of CCS has grown by 183%, as of September 2022, demonstrating the popularity of this technology as a method to meet environmental targets. With new technology and processes come new challenges, and CCS is no exception. This article aims to explore the issue of corrosion in amine systems and how the risk can be mitigated by high nobility cladding solutions.

Amine-based systems capture carbon dioxide (CO2) from industrial flue gases. However, these systems present a significant challenge when it comes to corrosion in process vessels due to the aggressive nature of the amine solutions. To address this issue, upgrading the metallurgy of process vessels through high nobility cladding offers an effective solution to prevent corrosion and extend the service life of the equipment.

Understanding Corrosion in Amine Systems

Amine systems involve the use of amines, such as monoethanolamine (MEA), as the solvent to absorb CO2 from flue gases. The amine solutions are highly corrosive, particularly in the presence of oxygen and heat, leading to the degradation of process vessel materials. Corrosion in these systems can result in reduced operational efficiency, increased maintenance costs, and even potential safety risks.

There are several corrosion mechanisms that can occur in CCS amine systems:

It occurs uniformly across the metal surface and leads to a gradual thinning of the metal over time.

Pitting is localized corrosion that leads to the formation of small holes or pits on the metal surface. This type of corrosion can be particularly dangerous as it can cause sudden failures in the equipment.

- Stress Corrosion Cracking (SCC)

SCC is the cracking of metals under the combined influence of tensile stress and a corrosive environment. Amine systems can create conditions that promote SCC, leading to catastrophic failures in stressed components.

- Corrosion by CO2 Decomposition Products

CO2 degradation products like carbamate and bicarbonate can also contribute to corrosion in the amine system.

Upgrading Metallurgy with High Nobility Cladding

To combat corrosion in amine system process vessels, upgrading the vessel's metallurgy through high nobility cladding has proven to be an effective solution. High nobility cladding involves the application of a protective layer of noble metals, for example, an alloy of Chromium, Nickel, and Molybdenum, onto the surface of the vessel. This cladding provides enhanced resistance to corrosion and extends the vessel's service life.

Benefits of High Nobility Cladding

High nobility cladding materials offer superior resistance to corrosion, even in aggressive amine environments. The protective layer acts as a barrier, preventing direct contact between the amine solution and the base metal.

By upgrading the process vessel's metallurgy, high nobility cladding significantly reduces the occurrence of corrosion-related failures. This leads to improved operational reliability and a decrease in unplanned downtime.

The implementation of high nobility cladding enhances the durability of process vessels, resulting in extended service life. This allows for a more cost-effective and sustainable operation of the CCS amine system.

- Installation and Maintenance Considerations

The successful application of high nobility cladding in amine system process vessels requires careful planning and execution. Key considerations include:

- Surface Preparation: Proper surface preparation, including cleaning and pre-treatment, is crucial to ensure optimal adhesion of the cladding material.

- Cladding Selection: The selection of the appropriate cladding material should consider the specific corrosion resistance requirements of the amine system. Stainless steel, nickel alloys, or other high-nobility materials are commonly used for this purpose.

- Quality Control: Rigorous quality control measures should be in place during the cladding process to ensure the integrity and effectiveness of the protective layer. Non-destructive testing methods can be employed to detect any defects or discontinuities.

- Regular Inspections: Periodic inspections should be conducted to monitor the condition of the cladding and identify any signs of degradation or damage. This allows for timely maintenance and repairs to maintain the corrosion protection.

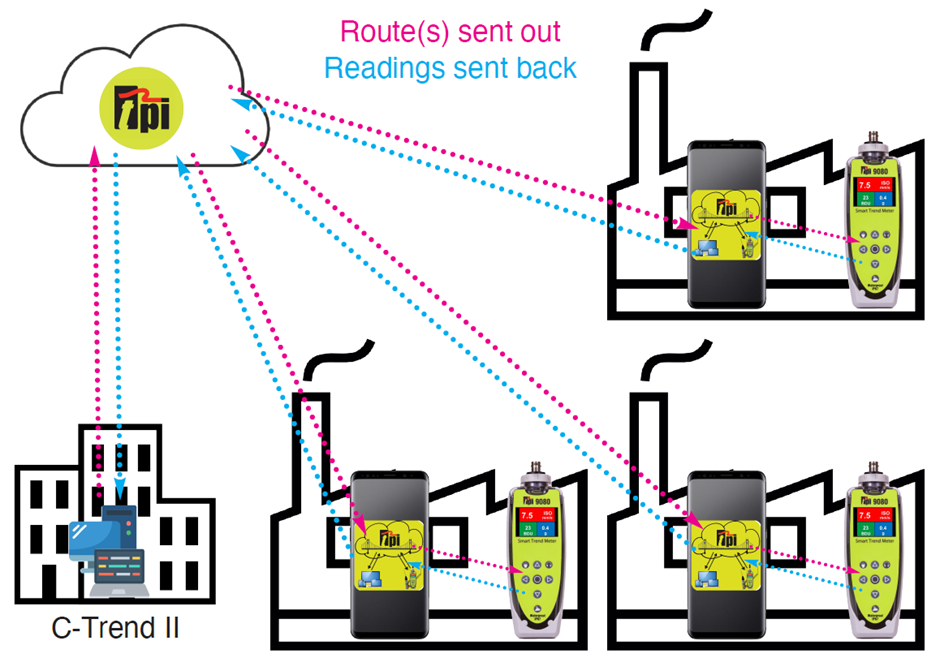

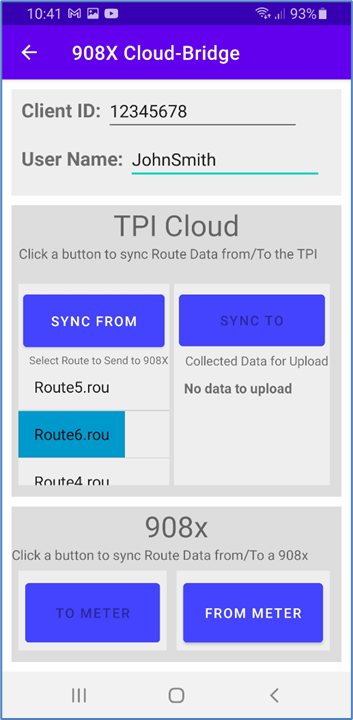

Introduction to HVTS

High Velocity Thermal Spray (HVTS) is a proprietary high nobility cladding solution developed by Integrated Global Services (IGS). Due to its superior corrosion protection properties, it is referred to as a cladding, rather than a coating. HVTS involves the on-site application of a high-alloy corrosion-resistant cladding that consists of flat and tightly packed micro-sized metallic particles.

HVTS provides excellent value and results for protecting amine systems from corrosion and improving longevity at a fraction of the cost and time of weld overlay.

The Benefits of HVTS

A cladding solution, specifically HVTS, has many benefits for carbon capture and storage plants. The benefits include:

HVTS cladding provides excellent protection against corrosion. The dense and tightly bonded cladding acts as a protective barrier. This helps extend the lifespan of the amine system, reduces maintenance requirements, and enhances overall reliability.

- No Dilution or Heat Affected Zone (HAZ)

Unlike Weld Metal Overlay (WMO), HVTS does not generate a Heat Affected Zone (HAZ) and does not place residual stresses on the base metal as the temperature of the base metal remains low.

- Refurbished or Replaced In-situ

HVTS can be reliably refurbished or even replaced in situ without replacing the underlying component. This contrasts with 625 weld-overlaid components which must be replaced at the end of life.

HVTS cladding can be applied relatively quickly, making the process efficient for large-scale industrial applications. The high-velocity spraying technique enables fast coverage of large surface areas, reducing downtime and production interruptions.

HVTS and other high nobility claddings offer a cost-effective solution for extending the service life of components and equipment. By providing corrosion and wear protection, the cladding can reduce the frequency of component replacements and maintenance requirements, resulting in cost savings over time.

HVTS cladding can contribute to achieving environmental targets. By improving the durability and longevity of components, they help reduce the consumption of resources and minimize waste generated from frequent replacements. Additionally, HVTS can enhance the energy efficiency of equipment, leading to reduced energy consumption and lower CO2 and NOx emissions.

HVTS Cladding Process and Application

The application of High Velocity Thermal Spray (HVTS) to amine systems is always undertaken by trained IGS cladding technicians as training and expertise in HVTS application techniques are crucial to achieving high-quality and reliable cladding.

The application of HVTS involves the following steps:

- Surface Preparation

The surfaces of the metal need to be properly prepared before the application of HVTS cladding. This typically involves cleaning the surfaces to remove contaminants such as rust, scale, oil, or any other substances that could affect the adhesion of the cladding. Mechanical methods like grit blasting or wire brushing are sometimes used for surface preparation if required.

- Cladding Selection

The appropriate HVTS cladding material is selected based on the specific requirements, such as corrosion resistance, wear resistance, or thermal insulation.

- HVTS Equipment Setup

The HVTS equipment, including the spray gun, gas supply system, and control unit, is set up according to stringent IGS guidelines and specifications. The system is calibrated to ensure accurate and consistent application of the cladding.

- Application of HVTS Cladding

The HVTS cladding is applied using a high-velocity thermal spray gun. The gun atomizes a proprietary wire feedstock in a supersonic gas stream, producing a cladding that consists of flat and tightly packed micro-sized particles.

- Post-application and Quality Assurance

Quality control measures, such as visual inspection, thickness measurement, and adhesion testing, are conducted to ensure the integrity and effectiveness of the HVTS cladding. Any necessary touch-ups or rework can be performed if required.

High Nobility Cladding Application Experience

Integrated Global Services (IGS) has extensive experience and expertise in addressing corrosion challenges in amine systems. With a proven track record in the field of corrosion protection and metallurgical upgrades, IGS has successfully implemented high nobility cladding solutions in numerous amine system process vessels over the last 30 years.

A deep understanding of the corrosive nature of amine solutions and the detrimental effects they can have on process vessel metallurgy, is important. Leveraging industry knowledge and advanced technologies, IGS has developed tailored solutions to combat corrosion and enhance the performance and longevity of amine system equipment.

Through years of research and practical application, IGS has honed their cladding techniques to ensure optimal adhesion and corrosion resistance. Their team of highly skilled technicians follows stringent quality control measures during the cladding process, ensuring the integrity and effectiveness of the protective layer.

Moreover, IGS provides comprehensive corrosion assessment services, leveraging expertise to identify vulnerable areas in amine systems. By conducting thorough inspections and evaluations, recommendations can be made and implementation of the most suitable cladding materials and techniques to prevent corrosion and extend the service life of process vessels can be undertaken.

Preventing corrosion in amine system process vessels is crucial for the successful and sustainable operation of carbon capture and storage facilities. Upgrading vessel metallurgy through high nobility cladding offers an effective solution to combat corrosion, extend equipment service life, and ensure operational reliability. By implementing high nobility cladding, CCS operators can mitigate the adverse effects of amine corrosion, reduce maintenance costs, and contribute to the long-term viability of carbon capture technologies in the fight against climate change.

Find out more: www.integratedglobal.com