When faced with metal wastage, asset owners and operators can address the corrosion mechanisms with a corrosion-resistant alloy (CRA) barrier. The technique used to apply this CRA will mainly be determined by the shutdown time available to carry out the application.

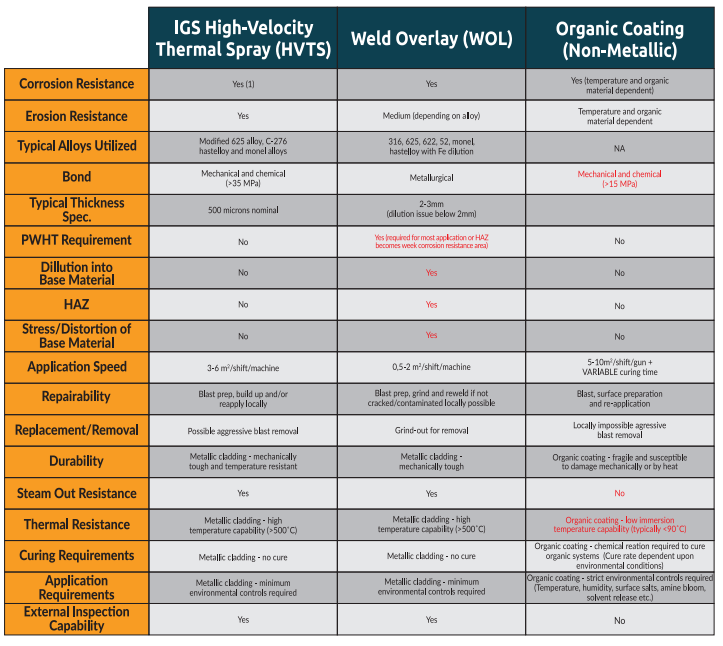

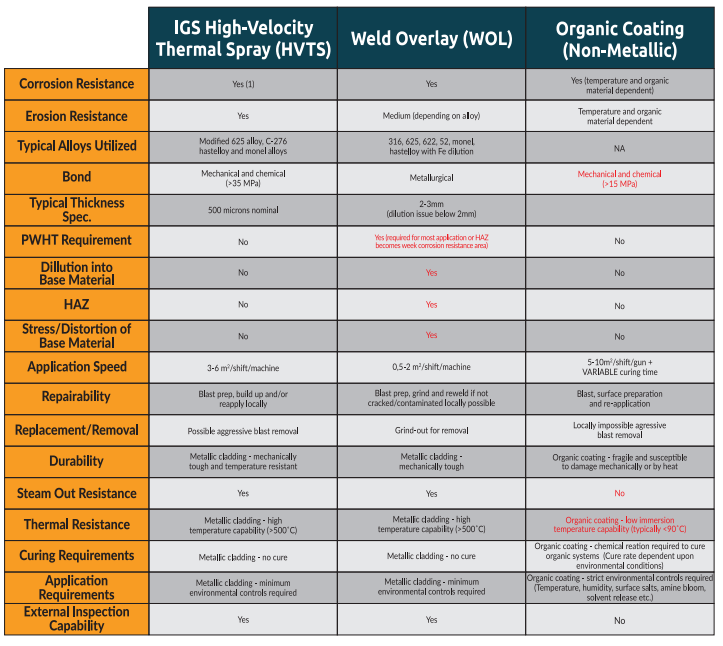

While weld metal overlay remains a reliable option, laboratory testing and performance validation, field application, and subsequent site inspections of High Velocity Thermal Spray (HVTS) alloy cladding projects have confirmed this solution to perform “in the same league” with several added benefits.

The Evolution of High Velocity Thermal Spray

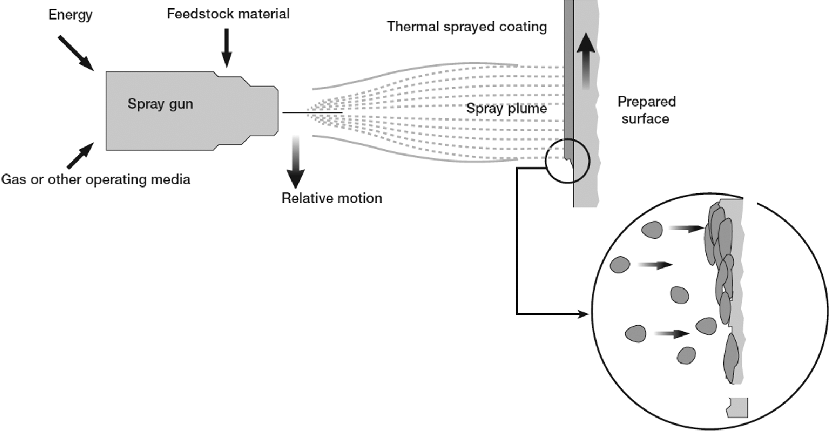

Thermal spray technology has been utilized for the application of CRA since the 1980s, spraying metals widely used for corrosion protection. However, it was quickly noted that the thermal spray process itself can negatively affect the condition of the material being sprayed. The resulting cladding, when using traditional metal alloys and commercially available thermal spray equipment has not been able to create a sufficient barrier to corrosive media.

Permeability coupled with internal stress and lower bond strength with the base metal creates a path for corrosion and premature failure. These early failures resulted in an understandable and rather universal distrust of early iterations of commercially available thermal spray technology.

Engineering a Solution

Engineers and material scientists have successfully developed a solution to this problem by redesigning both the equipment used to apply the metal cladding, the process technology, and the alloy of the feedstock material.

True High Velocity

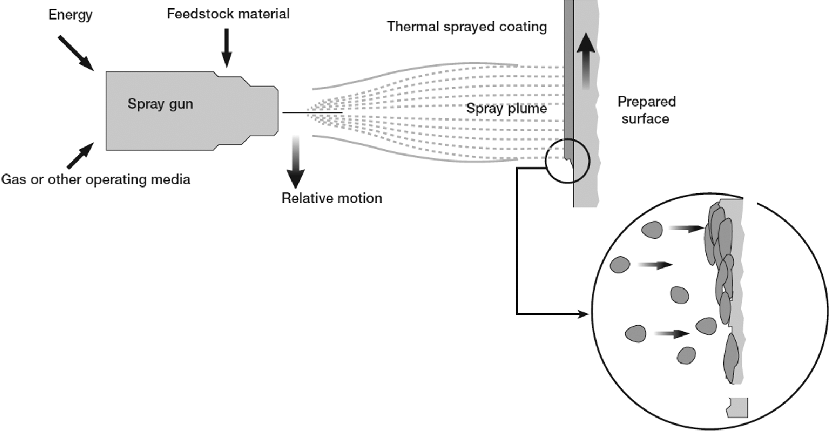

The atomization velocity is a critical success factor in thermal spray cladding for critical equipment liquid and gas corrosion environments. For thermal spray cladding applied with a wire feed stock, a high velocity process is defined where the material atomization occurs in a super-sonic gas stream (gas stream velocity equal to or greater than Mach 1) which results in specific particle characteristics critical to achieving an impermeable barrier.

Creating an Impermeable Barrier

As particles are ejected from the thermal spray torch at high temperature and velocity, they are exposed to air with a high nitrogen and oxygen content. The molten particles are inclined to rapidly oxidize in flight. On deposition, oxide bands are formed in layers along with the metal splats.

These oxide structures constitute permeable pathways through the applied thermal spray and are to be avoided in any application, especially where corrosion is present. Chemical and process controls are employed to significantly inhibit in-flight oxide formation.

Bond Strength

The problem of bond strength, both between the applied metal particles and the substrate, was solved by increasing velocity and improving the quality of the substrate surface preparation. When the molten metal particles hit the substrate with a suitable profile at speeds close to supersonic, they splat and embed metal into the substrate, forming tight bonds. The particles themselves do not have a perfectly smooth microstructure; this feature promotes good intersplat adhesion. Multiple additional overlapping passes of the thermal spray torch then create a 500-micron thick cladding with excellent adhesion throughout. ASTM adhesion pull-off tests measure bond strengths of 30 - 60MPa.

Case Study 1: Fixing Failed Low Velocity Thermal Spray Coatings

The Problem

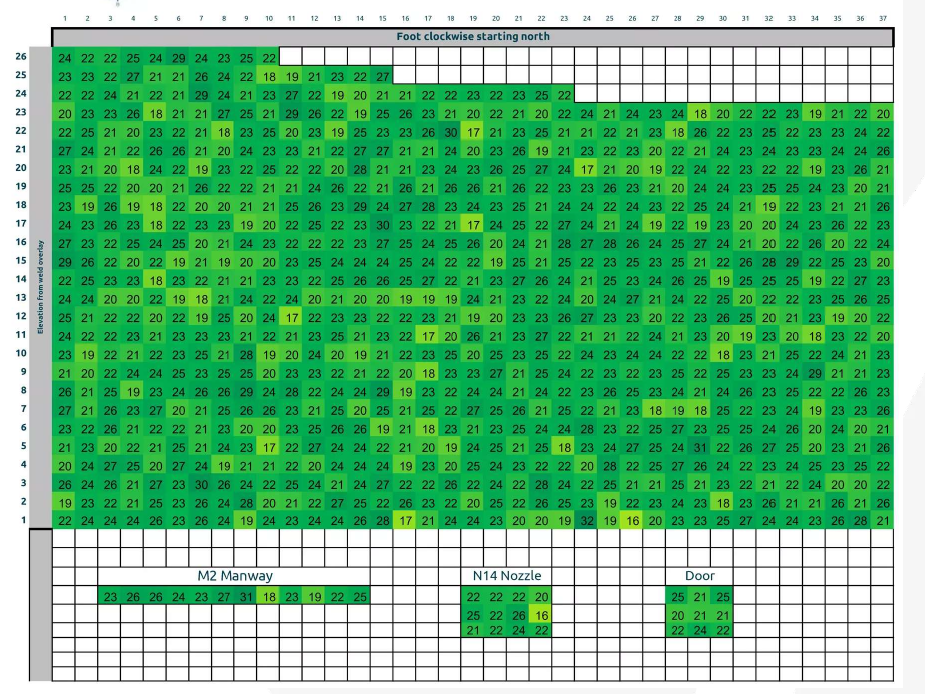

A US refinery identified a problem with its second stage desalter and overhead accumulator vessels during a routine inspection.

A nickel-copper thermal spray coating had been applied in both vessels approximately 20 years ago. Initially, the coating performed as expected. However, after some time, localized damage was evident on the bottom third of both vessels, leading to deep pitting and metal wastage beyond the existing corrosion allowance.

Thermal Spray Coating and Weld Failures

Typical thermal spray coatings are not suitable for internal protection of mission critical process equipment due to their permeability, weaker bond strength and propensity to cracking. These “low velocity” thermal spray systems cannot produce flat and tightly packed particle sizes or nano-scale grain structures, leading to the coating’s failure due to corrosion and/ or permeation.

Furthermore, weld repairs were also attempted, adjacent to the failing thermal spray, and a crack had formed on its heat affected zone (HAZ). In 2017, refinery engineers decided they needed a more permanent solution.

The Solution

An HVTS alloy cladding solution was chosen to stop corrosion for the expected life of the asset without any further maintenance anticipated for at least the next 15+ years.

HVTS technology utilizes alloy materials, which offer erosion-corrosion protection, even in high-temperature and high-pressure service up to 1371°C/2500°F.

The cladding option also offered significant time savings compared with weld overlay. As a result, the refinery project manager welcomed the solution, and HVTS was applied in the Spring of 2019.

The bottom third of the overhead accumulator, including the stem pipe with a vortex breaker and a flange, were protected with HVTS. Regular inspections have shown no deterioration of the cladding since application.

Key Benefits of HVTS

- More Robust than Organic Coatings

HVTS is considered more robust than organic coatings for several reasons. Firstly, HVTS relies on mechanical bonding to the substrate; molten particles are propelled at high velocities creating a bond that is inherently stronger than the adhesive bond typical with organic coatings.

Furthermore, HVTS has a higher immersion temperature resistance which makes it often chosen for applications involving immersion in aggressive substances. Its resistance to immersion at elevated temperatures surpasses that of organic coatings, which may experience degradation or chemical breakdown when exposed to corrosive liquids or gases.

For example, TCO in Kazakhstan holds 26 billion barrels of oil and gas and has a high sour gas (hydrogen sulfide or H2S) content of about 6%. The plant identified major corrosion and process vessel integrity issues due to earlier applications of organic coatings. These coatings are often solvent-based, and in these instances, apart from other limitations, problems are experienced due to solvent retention within the film. This retained solvent will then increase in volume as it is exposed to higher temperatures, which in turn leads to blistering.

In contrast, the robustness of HVTS compared to organic coatings can also be attributed to its hardness, temperature resistance, flexibility in thickness and resilience to mechanical and chemical stresses.

- More Cost-effective than Weld Overlay

HVTS offers several cost-effective advantages over traditional weld overlay methods, such as:

- Reduced Downtime and Faster Application

HVTS has a faster application process compared to weld overlay. Traditional weld overlay involves time-consuming welding procedures, which may require the shutdown of equipment or entire facilities. In contrast, HVTS can be applied more rapidly, minimizing downtime, and allowing for quicker return to service. The efficiency of the application process contributes to overall cost savings by reducing the impact on production schedules and operational continuity.

- No Heat-Affected Zones (HAZ)

Weld overlay introduces heat-affected zones (HAZ) in the substrate material due to the welding process. These zones can experience changes in metallurgical properties, potentially leading to issues such as reduced material strength or increased susceptibility to corrosion. HVTS, being a thermal spray process, does not generate HAZ. This eliminates the need for post-weld heat treatment and reduces the risk of material degradation, simplifying the overall process and reducing associated costs.

Other factors that make HVTS a more cost-effective option include lower equipment and labor costs, material savings, and the elimination of post-weld inspections.

Case Study 2: ½ The Cost and ⅓ The Application Time in LP Separator Renewables Conversion

Introduction

A multinational oil and gas company has been focusing on meeting the world’s growing energy needs while reducing its carbon emissions intensity. As a result, it converted one of its refineries to a renewable fuels manufacturing and terminal facility to be able to produce approximately 730 million gallons of renewable fuels per year.

The Problem

A low-pressure separator with minimum corrosion allowance remaining was being prepared for renewable diesel conversion to mitigate the risk of carbonic acid attack in the new operating environment. The plant considered welding internal cladding, but that option carried significant costs and would require 30 shifts to apply.

The Solution

The plant selected HVTS to upgrade the metallurgy of the separator to a higher nobility alloy able to prevent carbonic acid corrosion. References, operational excellence, and the ability to inspect the separator in between turnarounds without shutting it down were the key drivers for the plant’s decision. The application cost 50% less than weld metal overlay would have cost and was applied in one-third of the time.

Solving Complex Challenges with HVTS

Case Study 3: Chloride Stress Corrosion Cracking in Critical Process Assets

Chloride-induced Stress Corrosion Cracking (CSCC) poses a significant threat to the structural integrity of critical process vessels and hence the process safety of the plant.

This form of corrosion cracking can be challenging to effectively monitor with inspection and once initiated can lead to catastrophic failures if not addressed effectively.

Why does CSCC Occur?

This phenomenon occurs due to a combination of three key factors: the presence of chlorides in the process fluids, tensile stress in the substrate material, and elevated operational temperatures. When these three factors combine, they create a corrosive environment that initiates micro-cracks or micro-pits in the stainless-steel surface. These cracks become the focal points for localized corrosion and can propagate rapidly under the influence of the applied tensile stresses, particularly in Heat Affected Zones or areas of higher material hardness. Austenitic stainless steels, which are commonly used in process vessels due to their excellent corrosion resistance and mechanical properties, are particularly susceptible to CSCC.

The Problem

In this case, IGS was contracted to combat CSCC in six critical process vessels offshore in the Arabian Sea operated by an LNG corporation: four discharge drums, and two condensate strippers.

The Solution

To mitigate CSCC in its process vessels, the HVTS cladding was applied. It delivered an effective corrosion barrier against chloride penetration, isolating the asset substrate from the chlorides in the process fluid, thus preserving the integrity and safety of critical process vessels in the high chloride environment.

After ten years in service and three outages/ inspections, all the applied cladding was found to be in its original condition, devoid of any cracks, blistering, or delamination.

ESG Considerations

HVTS is considered advantageous for Environmental, Social, and Governance (ESG) objectives due to its specific characteristics and performance attributes, such as:

Reduced Environmental Impact:

The application of HVTS often involves fewer environmental concerns compared to alternative methods like traditional weld overlay. HVTS typically generates fewer emissions and requires less energy during the application process, contributing to a lower overall environmental footprint.

ESG Reporting and Compliance:

Utilizing HVTS for corrosion protection aligns with ESG reporting and compliance requirements. Organisations that adopt technologies with environmental benefits, such as HVTS, can demonstrate a commitment to sustainability in their reporting and contribute to a positive ESG score.

Long-Term Sustainability:

HVTS coatings are designed for durability, providing long-term protection against corrosion. This longevity aligns with sustainability goals by reducing the frequency of coating applications and associated resource consumption over the asset's lifecycle.

Case Study 4: HVTS and ESG

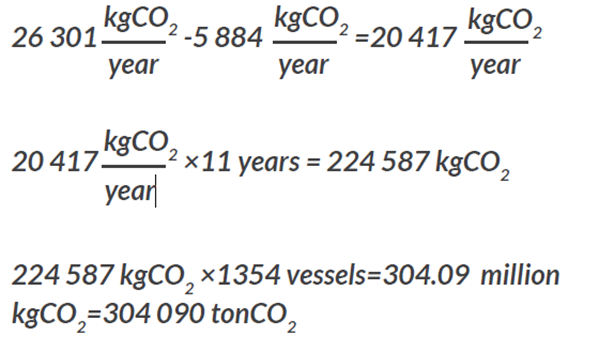

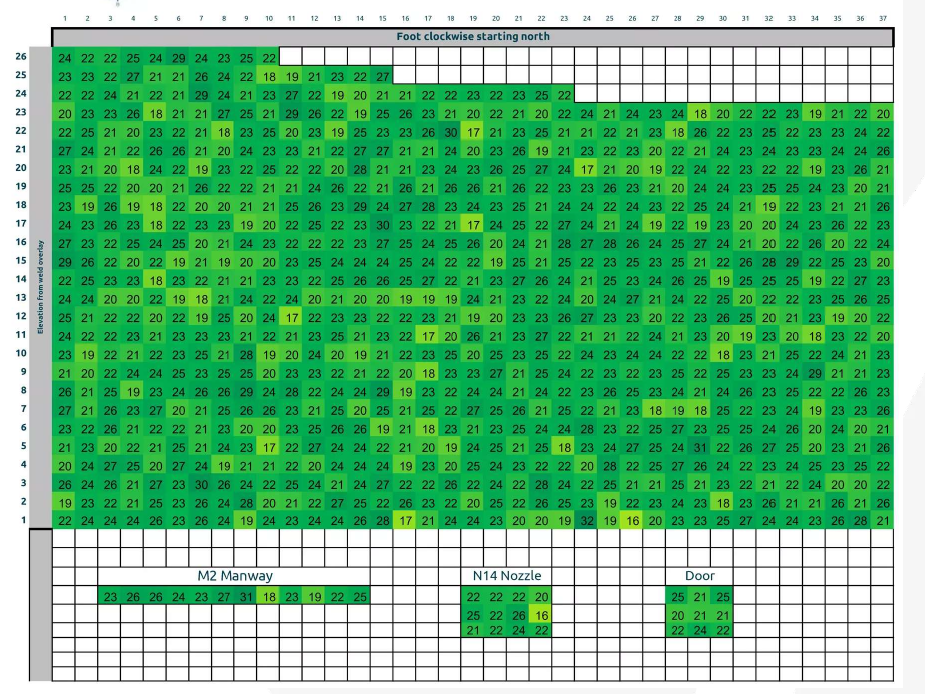

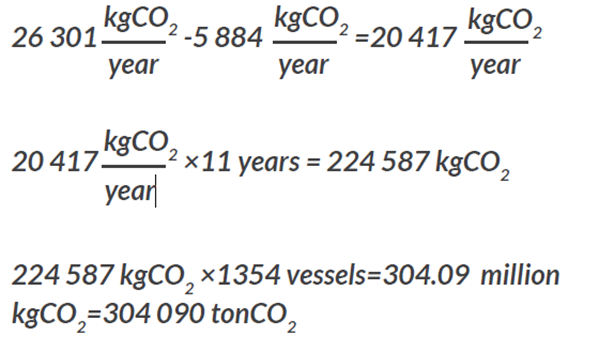

A recent ESG case study conducted by Integrated Global Services (IGS) shows a breakdown of the O&G projects that IGS has completed since 2012. Looking at the statistics of 1354 projects, with an average scope of 680 sqft. each, for only the past 11 years the following calculation can be done to determine the amount of carbon dioxide that would potentially have been released into the atmosphere if those vessels had to be replaced.

304,090 tonCO2 is equivalent to 703,340 barrels of oil consumed or 340,627,459 pounds of coal burned.

Conclusion: Advancing Corrosion Mitigation for Sustainable Industrial Practices

In the ever-evolving landscape of corrosion mitigation technologies, the journey from conventional methods to cutting-edge solutions like HVTS has been transformative. As we navigate the lessons learned from thermal spray applications in process vessels and columns, a clear narrative emerges—a narrative of innovation, quality standards, and sustainable practices.

CRA technologies signify a commitment to a future where corrosion mitigation goes hand in hand with environmental responsibility and operational efficiency. With each use case, HVTS reinforces its role as a cornerstone in the pursuit of a corrosion-free, sustainable industrial landscape.

www.integratedglobal.com