Cal-Bay Systems announces a powerful PC based rotating equipment monitoring system for recording and analyzing machine-rotating parameters such as vibration levels and frequency, angular speed and rotational displacement.

Cal-Bay Systems announces a powerful PC based rotating equipment monitoring system for recording and analyzing machine-rotating parameters such as vibration levels and frequency, angular speed and rotational displacement.The REMS-100 system is a cost-effective, integrated machine monitoring solution, using National Instruments hardware and ready to run software. It is supplied as a fully engineered, turn-key system. The REMS-100 base system can be also customized to meet specific customer requirements. Additional services are available for field start-up, installation and system maintenance.

- HR.jpg) Monitran announces its “Grip Tight” bodied vibration sensors and accelerometers

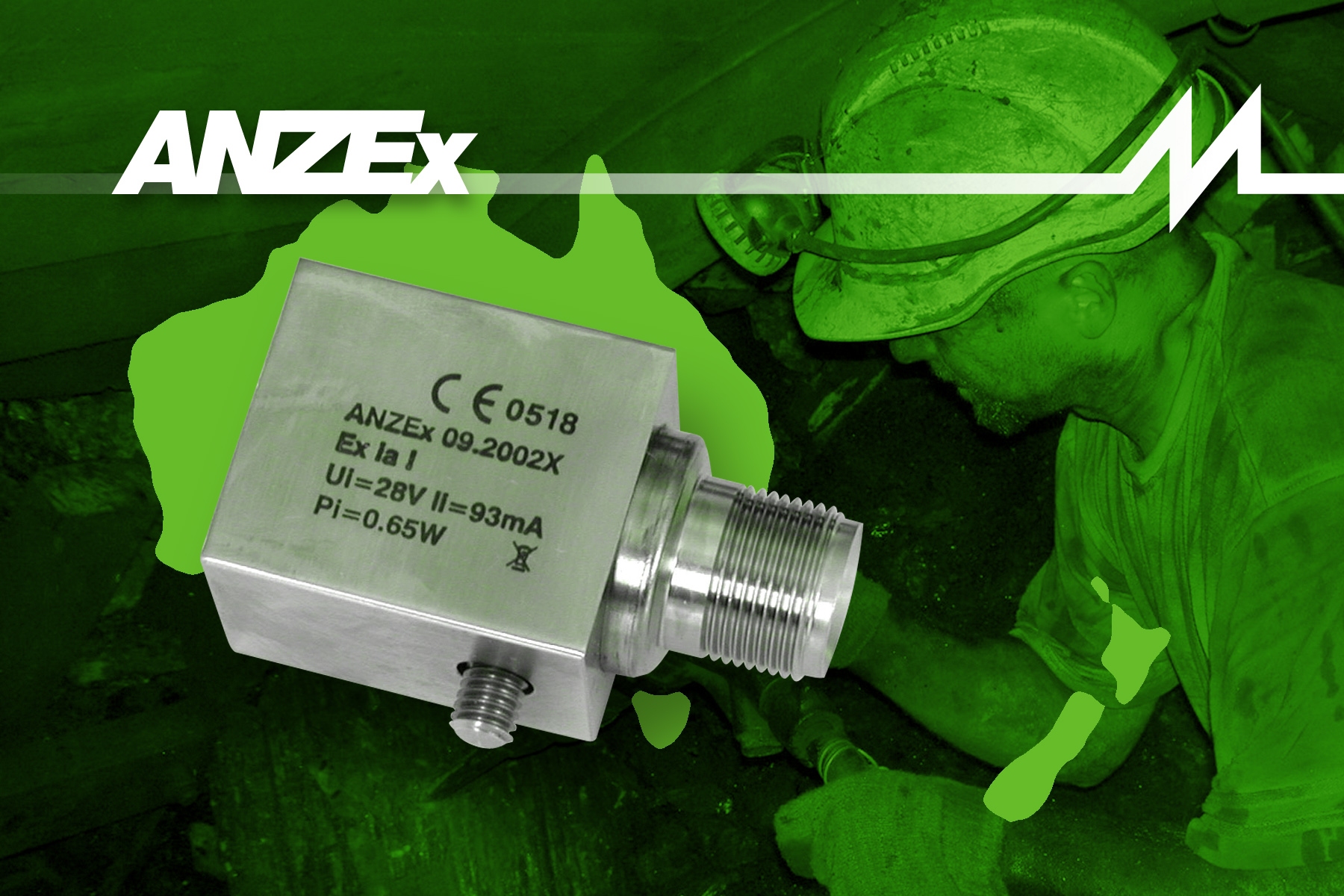

Monitran announces its “Grip Tight” bodied vibration sensors and accelerometers Monitran’s Group I intrinsically safe sensors are awarded ANZEx for use in mining applications in Australia and New Zealand.

Monitran’s Group I intrinsically safe sensors are awarded ANZEx for use in mining applications in Australia and New Zealand. It is common knowledge that a range of Condition Monitoring (CM) techniques are available such as Vibration Analysis, Oil & Wear Debris Analysis, Thermography and Acoustic Emission. Each of these techniques has its own particular areas of strength and in this regard the Acoustic Emission (AE) technique has the noted advantage of giving real time information with early sensitivity to faults and applicability to a wide range of rotational speeds including slowly rotating (source : ISO 22096).

It is common knowledge that a range of Condition Monitoring (CM) techniques are available such as Vibration Analysis, Oil & Wear Debris Analysis, Thermography and Acoustic Emission. Each of these techniques has its own particular areas of strength and in this regard the Acoustic Emission (AE) technique has the noted advantage of giving real time information with early sensitivity to faults and applicability to a wide range of rotational speeds including slowly rotating (source : ISO 22096).

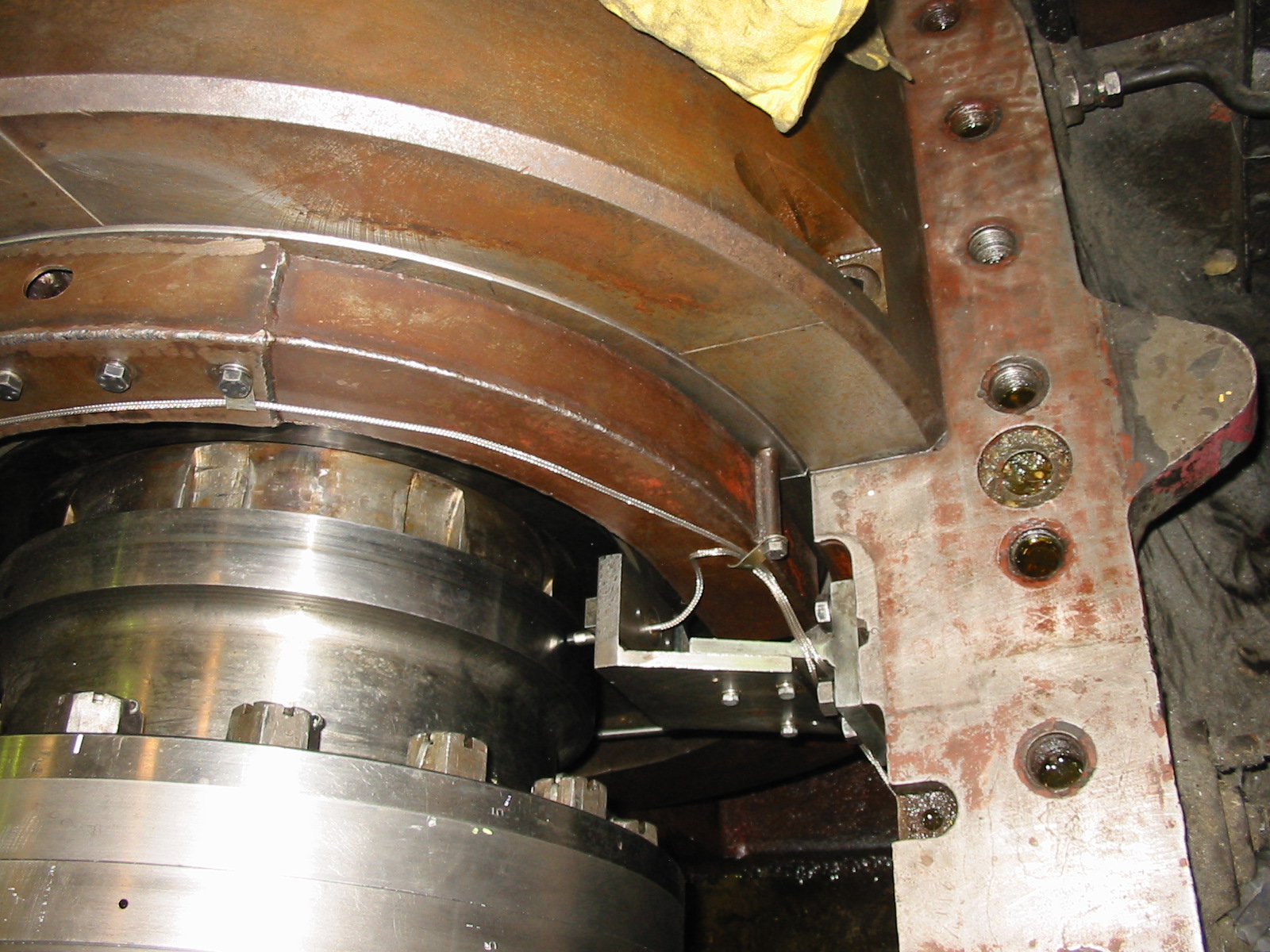

Condition monitoring specialists SENSONICS have made an important contribution to the upgrade of turbine supervisory and vibration monitoring installations at the Uskmouth Power Station in Newport, South Wales.

Condition monitoring specialists SENSONICS have made an important contribution to the upgrade of turbine supervisory and vibration monitoring installations at the Uskmouth Power Station in Newport, South Wales.

lists SENSONICS have introduced the Sentry G3 machinery protection monitor, a high performance signal conditioning unit. The new G3 monitor builds upon the established range of Sentry protection systems developed by Sensonics and is designed to be the most flexible and feature rich Turbine Supervisory System available. It provides a universal platform for the interfacing of various sensor types in compliance with the API 670 standard.

lists SENSONICS have introduced the Sentry G3 machinery protection monitor, a high performance signal conditioning unit. The new G3 monitor builds upon the established range of Sentry protection systems developed by Sensonics and is designed to be the most flexible and feature rich Turbine Supervisory System available. It provides a universal platform for the interfacing of various sensor types in compliance with the API 670 standard.

Hansford Sensors Ltd. now offer a range of submersible vibration sensors, which has been specifically designed for operation in partial or complete immersion in water, making them ideal for the monitoring of pumps in a maintenance role.

Hansford Sensors Ltd. now offer a range of submersible vibration sensors, which has been specifically designed for operation in partial or complete immersion in water, making them ideal for the monitoring of pumps in a maintenance role.