GT, based in Cognac, France specialise in the manufacture of corrugated board for the packaging industry.

GT, based in Cognac, France specialise in the manufacture of corrugated board for the packaging industry.The operators in the packaging converting areas were being exposed to temperatures in excess of 350C. It is widely recognised that in high temperatures productivity falls, errors increase and absenteeism increases.

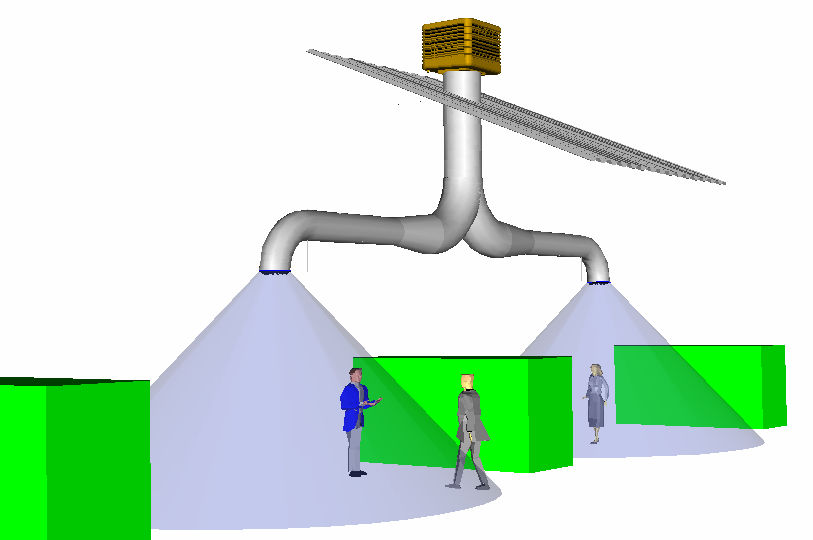

A single EcoCooler was used to supply a ducting system terminating in three swirl diffusers.

This was installed by using an upstand to replace a complete roofing sheet to provide a weather-proof fitting. Swirl diffusers were used to provide spot cooling for the individual operator work stations. These direct the air downwards and are suitable in extreme environments where positive air movements are required to overcome the heat generated in the area.

The angle of the conical shaped air distribution can be changed by altering the angle of the vanes in the diffuser.

The spiral wound ductwork was designed to produce a pressure drop of 125 Pa at a flow rate

of 12,000m3/hr.

Each work station receives approximately 4.000m3/hr at a height of 4m. This is equivalent to 35 air changes per hour in a 3m diameter area.

Increasing flow rates, smaller diameter ducts, bends etc all increase system resistance. If the

resistance is too high an axial fan will stall and there will be a rapid drop off of performance. All ductwork must be carefully designed to give the right balance between flow rate (avoiding stall conditions) and cost of installation.

www.ecocooling.co.uk