Surprisingly, many companies still use a system of Planned Periodic Maintenance in an attempt to avoid costly downtime arising from the failure of their equipment and machinery. In other words, they replace parts that tend to wear out (e.g. motor bearings) on a routine basis whether they need replacing or not. Not only is this needlessly costly, but can make matters worse by introducing faults during the process of stripping down and rebuilding a perfectly good machine. Even more of a problem is deciding the PPM time intervals. Too frequent, means more wasted time and cost (and more potential for introducing faults) but not frequent enough, means more unexpected breakdowns.

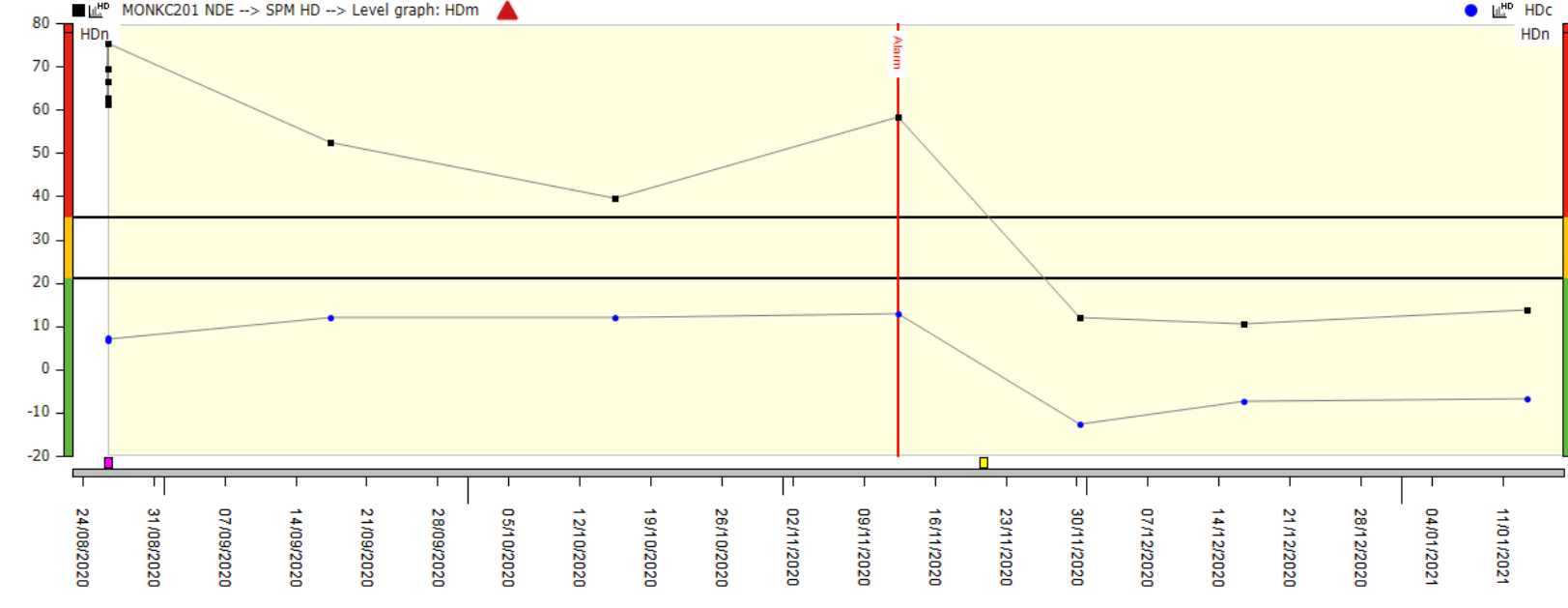

Condition Based Maintenance relies on the fact that a machine’s condition (degree of wear) can be monitored, by measuring the vibration levels in motor bearings for example. This way, the machine only needs to be maintained when its condition deteriorates beyond an acceptable level. This decision is based on recording and tracking changes in the machine’s condition over time (trending). Put simply, CBM philosophy is if it’s not broken, don’t try to fix it!

This approach obviously saves time and money since machine parts are only changed when they need to be. However, CBM can potentially save a lot of money by spotting a machine that is about to fail prematurely before it fails and hence avoid an unexpected and costly shutdown.

Clearly, CBM is a superior technique but until now, its cost of implementation has put off some companies from using it. Traditionally, both CBM equipment and the expertise required to use it has been prohibitively expensive.

Test Products International (TPI) has however completely revolutionised this concept with the introduction of its low cost, portable vibration analysers and free to use trending software. Both the analysers and software are very easy to use, stemming from the fact that they are very intuitive and based on internationally agreed (ISO) alarm levels for rotating machinery.

TPI’s free to use VibTrend machine management and trending software stores machine condition readings and displays their trends in a clear and easily understood graphical format. In addition, various ‘expert system’ features are incorporated into the software, such as bearing quality assessment, which is achieved by analysing the frequency components of the vibration data and automatically identifying the classic ‘signatures’ associated with bearing wear. That way, it is very easy to monitor the health of a bearing simply by observing the level of bearing quality displayed on the trend plots.

A complete CBM system can cost from as little as £1,450 with the TPI 9080, which uses industry standard accelerometers and offers on-meter analysis for the detection of machine faults such as unbalance, misalignment, looseness and bearing wear. The equivalent intrinsically safe version (IEC Ex, ATEX and North American) TPI 9080Ex offers a complete Zone 1 CBM solution for £3,500. Both versions include a full VibTrend free to use unlimited software license.

For more information please contact TPI Europe’s head office on +44 1293 530196 or take a look on the website at www.tpieurope.com or email This email address is being protected from spambots. You need JavaScript enabled to view it.

As part of its AIP+ (Added Value Programme), NSK’s Condition Monitoring Service (CMS) is a method to determine the health of machine components such as bearings while the machine remains operating. Indeed, data from the process can also be used to help determine (or at least narrow down) the causes of form errors when producing parts on grinding machines.

As part of its AIP+ (Added Value Programme), NSK’s Condition Monitoring Service (CMS) is a method to determine the health of machine components such as bearings while the machine remains operating. Indeed, data from the process can also be used to help determine (or at least narrow down) the causes of form errors when producing parts on grinding machines.  By using the capacity of cloud-based software to combine the real-time and historical data from Fluke Connect™-enabled tools and sensors, Fluke now enables maintenance engineers and managers to monitor a comprehensive picture of equipment health throughout the facility. The introduction of condition monitoring products that wirelessly transmit data from the field, combined with Fluke Connect Condition Monitoring (FCCM) software, has enabled safe, cost-effective maintenance programs. Maintenance teams can remotely detect potential equipment failures and remedy them before they cause costly downtime. Predictive maintenance is now not only simplified, but it is safer and faster.

By using the capacity of cloud-based software to combine the real-time and historical data from Fluke Connect™-enabled tools and sensors, Fluke now enables maintenance engineers and managers to monitor a comprehensive picture of equipment health throughout the facility. The introduction of condition monitoring products that wirelessly transmit data from the field, combined with Fluke Connect Condition Monitoring (FCCM) software, has enabled safe, cost-effective maintenance programs. Maintenance teams can remotely detect potential equipment failures and remedy them before they cause costly downtime. Predictive maintenance is now not only simplified, but it is safer and faster.  Spectrum analysis provides a great deal of information about the health of rotating machinery. But you should consider the spectrum as a summary of the vibration within the machine.

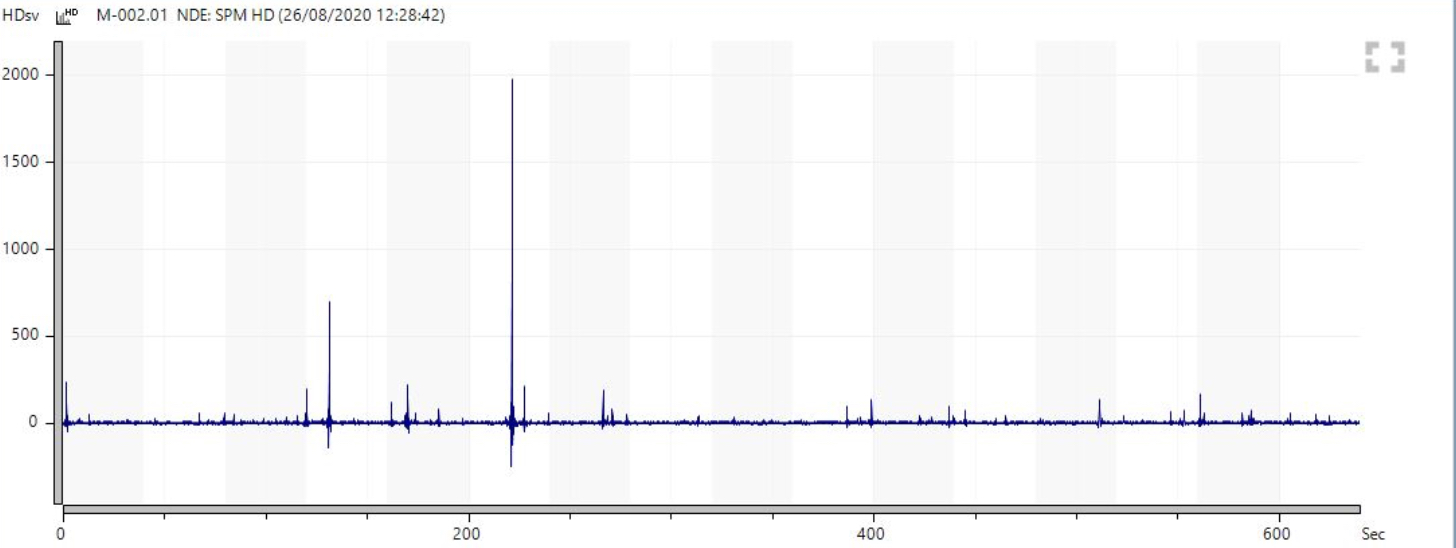

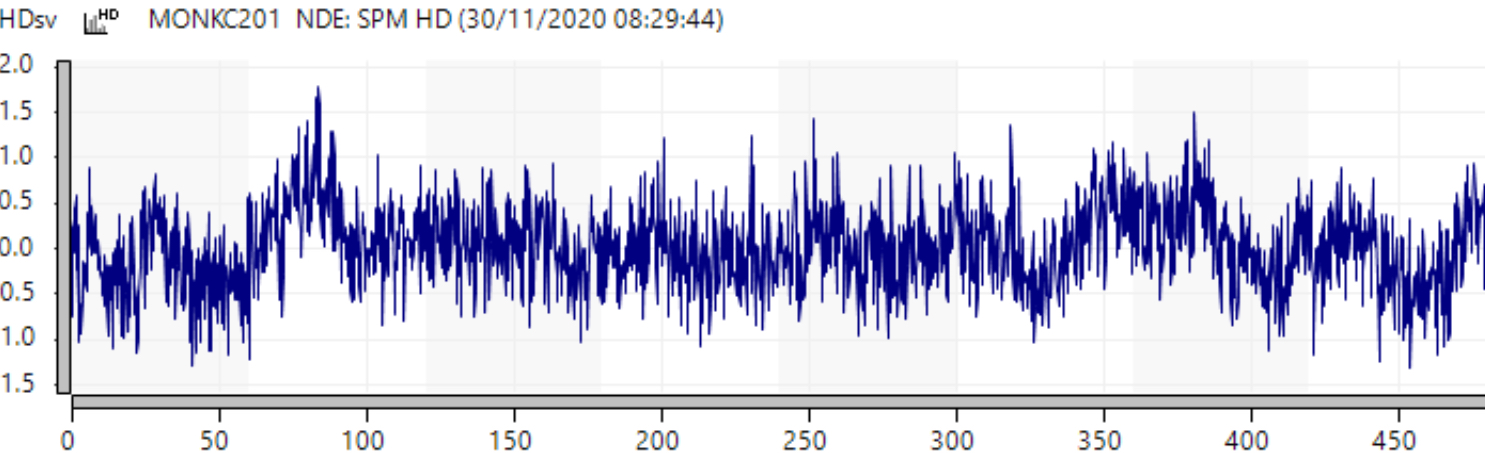

Spectrum analysis provides a great deal of information about the health of rotating machinery. But you should consider the spectrum as a summary of the vibration within the machine.  RUFTECHNIK expands its intelligent Online Condition Monitoring portfolio with VIBGUARD compact. As intelligent online CMS, the new VIBGUARD compact offers premium asset manufacturers of drivetrains and machines as well as their operators the same performance as its big brother VIBGUARD.

RUFTECHNIK expands its intelligent Online Condition Monitoring portfolio with VIBGUARD compact. As intelligent online CMS, the new VIBGUARD compact offers premium asset manufacturers of drivetrains and machines as well as their operators the same performance as its big brother VIBGUARD. On the 20th to 22nd of June, Manchester based condition monitoring specialist SPM Instrument UK Ltd. hosted a meeting with the CEO of SPM International and Managing Directors of its fourteen subsidiaries in Europe, USA, Singapore, and India.

On the 20th to 22nd of June, Manchester based condition monitoring specialist SPM Instrument UK Ltd. hosted a meeting with the CEO of SPM International and Managing Directors of its fourteen subsidiaries in Europe, USA, Singapore, and India.