”This case study describes the process of using the correct condition monitoring technique to monitor Rotating Biological Contactor (RBC) main bearings at 1RPM”

Severn Trent Water Asset Care Team were tasked with finding a reliable condition monitoring solution to monitor the main bearings of these RBC’s as when they fail they have huge consequences to the business. These RBC’s are usually located in remote sites and are difficult to keep track of with each area maintenance team having planned inspections but no real idea of condition.

SPM HD is proven to be the ideal condition monitoring solution for monitoring the lubrication decrease and early signs of damage on these bearings, other techniques such as ultrasound or Vibration Analysis could not detect these problems during previous trials. Due to SPM Technology proving itself Severn Trent Water decided to start with purchasing a Leonova Emerald initially then after presenting to the Directors they decided to invest in the same portable instruments for every area in waste water for Severn Trent. 38 Leonova Emerald instruments.

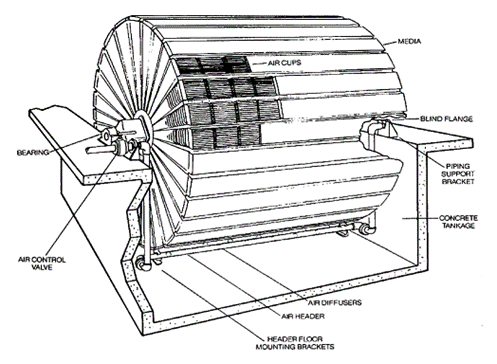

Rotating Biological Contactors (RBC) are an essential part of the water industry in remote areas. The RBC process allows the wastewater to come in contact with a biological film in order to remove pollutants in the wastewater before discharge of the treated wastewater to the environment.

Fig.1 A remote site with 2 RBC enclosures

Each RBC consists of a main bearing at either end of the main shaft. One side of the RBC has a Motor/Gearbox. The speed of the main bearings are fixed usually between 1.8rpm and 0.9rpm depending on the size of the RBC. The length from one main bearing to the other also varies depending on the type of RBC installed.

Fig.2 Construction of an RBC

Small discs with Biological fluid are in close proximity to each other which is called media. As the RBC rotates slowly these discs treat the water which then moves to the next part of the Treatment process.

There are over 500 RBC’s in Severn Trent Water in different locations around the area. They are all in remote sites which are difficult to access. When a main bearing fails they have to plan in the replacement which can take months as the lead time on the bearings is long as well as the installation of cranes and lifting equipment to remove the RBC.

Severn Trent Water had a number of these catastrophic failures resulting in them deciding to make plans to trial condition monitoring equipment.

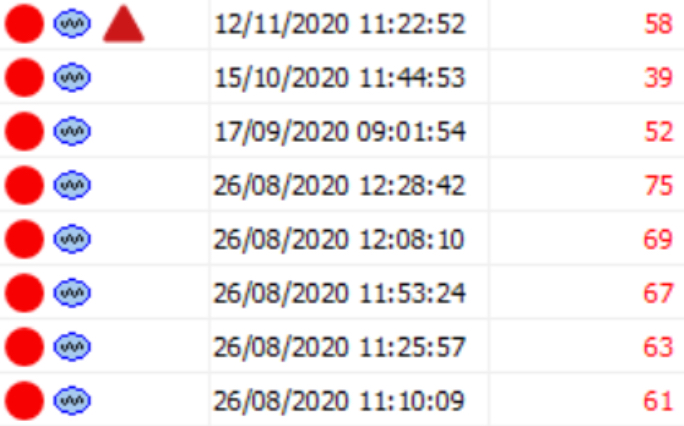

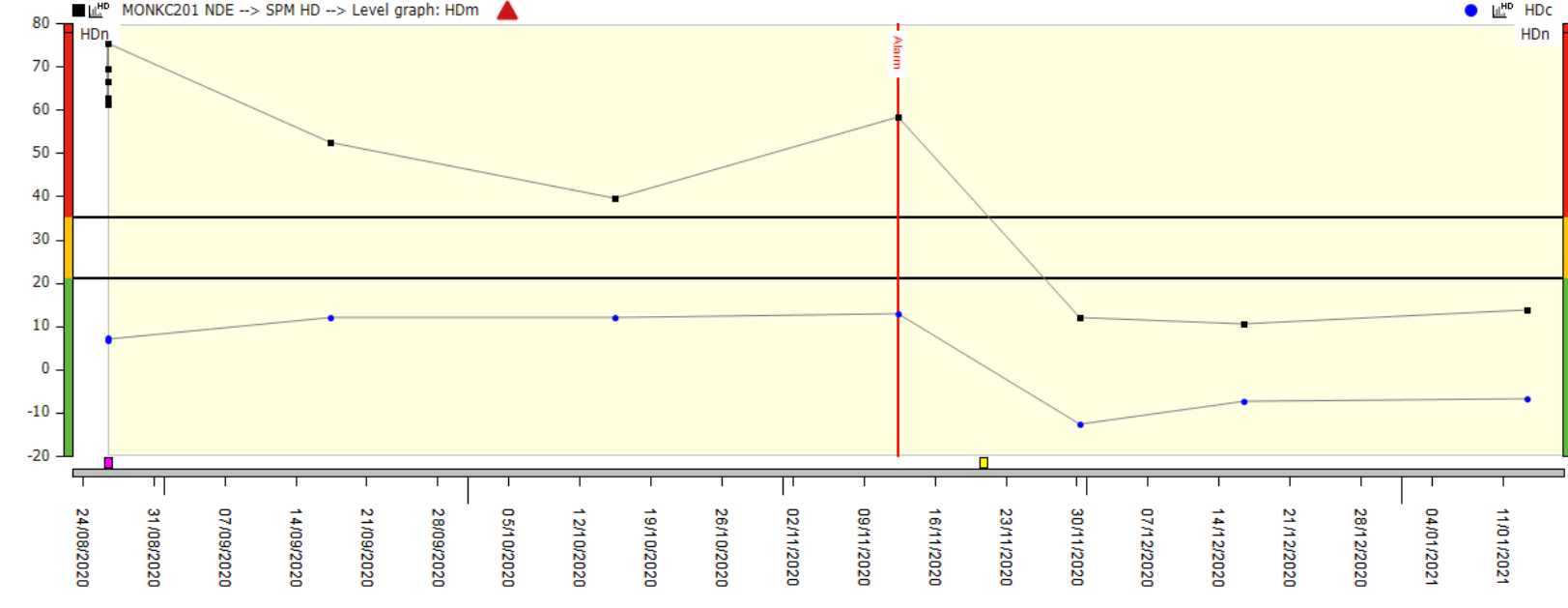

The initial readings on this asset was shown to be high in comparison to all other RBC’s. The below shows the overall SPM HD measurement results. The bearing was checked and repacked with grease showing a decrease in reading up until October

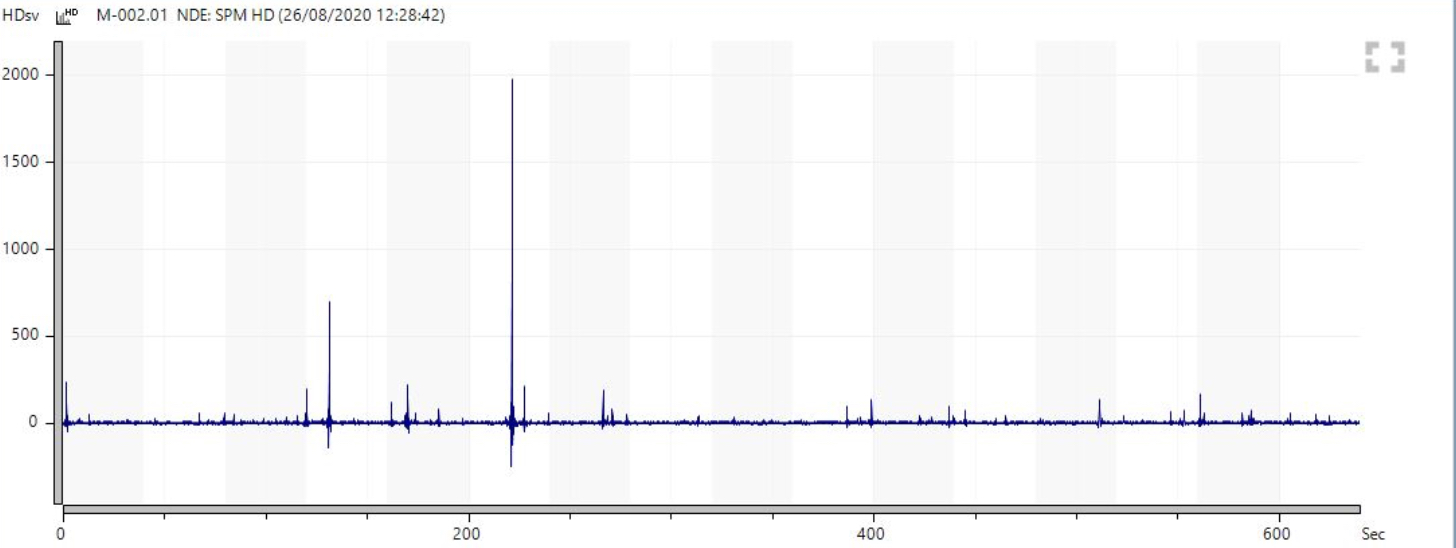

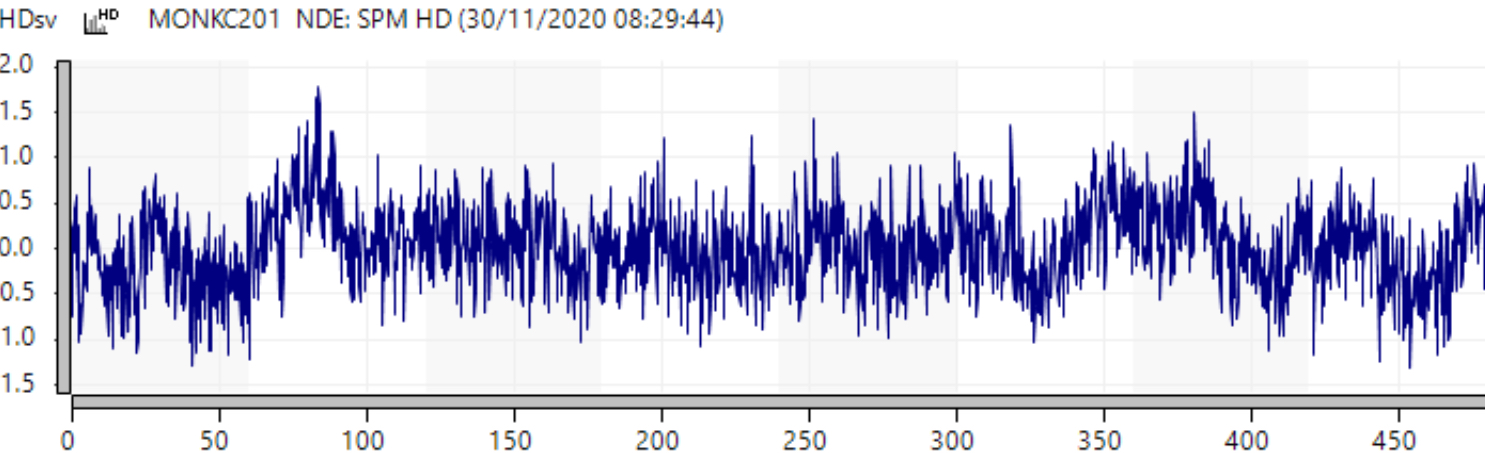

The overall SPM HD reading derives ultimately from the time signal reading below. This was confirmed that there was large impacts in the pressence of low readings indicating damage.

Corresponding Time signal

On relacement clear score marks could be seen around the shaft and damage was seen around the casing of the bearing and rollers. If this was left without monitoring it would have catastrophically failed.

Fig.9 Bearing pictures on replacement

After planned replacement the SPM HD readings reduced from alarm state to acceptable levels. The graph below shows the point when the bearing was replaced around the 20th November.

SPM HD Trend throught measurement lifetime

Time signal from healthy bearing