Manufactured vs. Die-Cast Rotors

Manufactured vs. Die-Cast Rotors

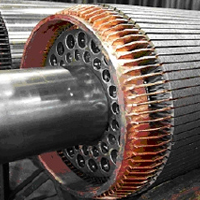

Squirrel Cage Induction Motors are of either a manufactured, or a die-cast design. Larger motors (above 300 to 500hp) will tend to be of the manufactured kind, being produced by inserting the rotorbars into the rotor slots first, and then connecting the bars to the end-rings. Copper is the most common material for such squirrel cages, but they can also be made of Aluminum, or even Brass in the case of the outer cage of a Dual-Cage rotor design. The squirrel cage of die-cast motors is typically aluminum, and in a few cases made of copper. Fig. 1 shows an example of a manufactured rotor and a die-cast rotor.

Porosity in Die-Cast Rotors

Porosity in Die-Cast Rotors

The die-casting process injects high pressure molten aluminum into the stacked rotor laminations, filling rotor bars and end-rings. Voids in the aluminum are a common imperfection of the die-casting process, and are called porosity. Manufacturers take many measures to avoid these imperfections, but slight amounts are frequently inevitable. Minor amounts of porosity will cause small cage damage signatures in vibration and MCSA, but will barely show a negative effect in the motor’s capabilities, operation, or its longevity. A little porosity shouldn’t cause concern for maintenance. The endring of a 150hp motor in Fig. 2 has extreme porosity. Such cases are very rare, showing poor motor performance under loaded conditions. Some motor manufacturers’ quality control test for such defects [3].

Managing Die-Cast Rotors showing Positive Cage Damage Results

Vibration and MCSA react equally to porosity as to damaged cages: Vibration and MCSA are the most sensitive diagnostic technologies for detection of cage damage of induction motors operated under loaded conditions. Both technologies are unable to distinguish the difference between porosity and broken or cracked bars or endrings. From a maintenance perspective, however, these cases are fundamentally different, since porosity requires no maintenance action, but a motor with a damaged cage does.

Advantage of knowing that a rotor is die-cast and not manufactured:

Advantage of knowing that a rotor is die-cast and not manufactured:

Manufactured rotors have an immediate catastrophic failure mode where parts of broken bars can loosen themselves into the airgap, causing stator windings to short against the stator core. This failure mode is so rare for die-cast designs, that it needn’t be considered.

Differentiating Rotor Porosity from Damaged Cage Rotors:

A rotor’s porosity has been there since manufacturing; it cannot worsen over time. Motors that have cage damage have developed that damage during operation, because their cage’s sturdiness doesn’t match the severity of the application in which they are being used. After the first damage, they are less capable of operating than before, and are more likely to develop further damage. This resembles a “slow avalanche” condition. Conclusion: When encountering Positive Results on die-cast rotor designs, it is best to put that motor on a “watch” list, increasing the frequency of diagnosis. If over time there is no worsening of the condition, it is safe to assume that there is no broken cage damage, just imperfections due to porosity. At this point it is safe to put the motor back into the typical maintenance monitoring cycle.

Lesson

Know Thy Rotor!!! The management of cage damage signatures of die-cast vs. manufactured rotor differ. It is of critical importance for maintenance programs to be aware which of their motors are die-cast, and which ones are manufactured. Have your motorshop document particulars of the rotor for every motor that is reconditioned! If possible, demand documentation from motor suppliers as well.

Further Reading:

Advanced Rotorbar Analysis: False Positives – Spiders / Axial Cooling

Vents Advanced Rotorbar Analysis: False Negatives – Dual Cage Rotors