More Editorial

Directory

This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE

Three years ago the munici¬pal authorities in the so-called Triangle Area of Denmark (Ve¬jle, Kolding and Fredericia in southwest Jutland) took a decision to modernise the re¬gion’s waste incineration plant.

Three years ago the munici¬pal authorities in the so-called Triangle Area of Denmark (Ve¬jle, Kolding and Fredericia in southwest Jutland) took a decision to modernise the re¬gion’s waste incineration plant.  Introduction

Introduction New KPI and Reports

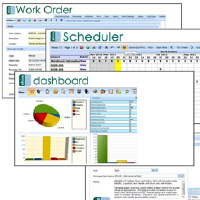

New KPI and Reports When flooring manufacturer Forbo introduced a Computerised Maintenance Management System the company reduced its plant breakdowns from 90 per month to less than 20, increasing plant availability from 89 per cent to 97 per cent.

When flooring manufacturer Forbo introduced a Computerised Maintenance Management System the company reduced its plant breakdowns from 90 per month to less than 20, increasing plant availability from 89 per cent to 97 per cent.

Pirana CMMS is designed for use by any size of organisation and is available as a hosted service as well as an on-premise setup. Those with a mobile workforce will find the advantages simply amazing. Users are able to get started straightaway and the on-going time saving is impressive.

Pirana CMMS is designed for use by any size of organisation and is available as a hosted service as well as an on-premise setup. Those with a mobile workforce will find the advantages simply amazing. Users are able to get started straightaway and the on-going time saving is impressive.

Thousands of companies rely on a Shire solution. Shire’s support is second to none, a result of a 30 year track record as the UK No 1.

Pirana is unbeatably affordable and is being adopted by many major players in the food, manufacturing and services arena. Sold in modules, including the popular Mobile Solutions, Pirana can revolutionise maintenance, stock, & purchasing operations. The system can be configured to users’ terminology / language and security requirements.

Shire also offers a FREE, no-obligation, fully functional trial system.

Key features

+44 (0)23 8022 4111

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.shiresystems.com

.jpg) The February 2010 edition of Engineering Maintenance Solutions magazine is now available to read online. This edition contains articles on achieving best practice in condition monitoring and plant maintenance. As well as special focuses on value driven maintenance, ATEX Equipment and more as well as the latest industry news and products.

The February 2010 edition of Engineering Maintenance Solutions magazine is now available to read online. This edition contains articles on achieving best practice in condition monitoring and plant maintenance. As well as special focuses on value driven maintenance, ATEX Equipment and more as well as the latest industry news and products. As assets become smarter and CMMS/EAM packages become more integrated across various asset classes within a manufacturing company, responsibility for facility management (including facility maintenance) has become spread over multiple departments. Historically, facility and plant maintenance were the sole responsibility of the Maintenance Department which ultimately reported to the Plant Manager or Works Manager. However, plant equipment is the focus of most Maintenance departments in a manufacturing environment, except in the largest and most complex multi-site facilities.

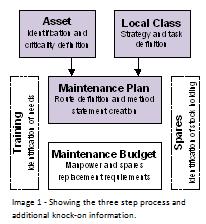

As assets become smarter and CMMS/EAM packages become more integrated across various asset classes within a manufacturing company, responsibility for facility management (including facility maintenance) has become spread over multiple departments. Historically, facility and plant maintenance were the sole responsibility of the Maintenance Department which ultimately reported to the Plant Manager or Works Manager. However, plant equipment is the focus of most Maintenance departments in a manufacturing environment, except in the largest and most complex multi-site facilities.  The contribution of maintenance to an organisation is unfortunately too often not fully understood until something goes wrong e.g. a failure of a significant plant item or asset.This will inevitably result in a consequential loss through the inability to produce or provide a service or the occurrence of an environmental health, safety or quality incident.

The contribution of maintenance to an organisation is unfortunately too often not fully understood until something goes wrong e.g. a failure of a significant plant item or asset.This will inevitably result in a consequential loss through the inability to produce or provide a service or the occurrence of an environmental health, safety or quality incident.  In Built to Last, authors Jim Collins and Jerry I. Porras determined that one factor in distinguishing a great company from a good one was what they called having “Big Hairy Audacious Ideas.”

In Built to Last, authors Jim Collins and Jerry I. Porras determined that one factor in distinguishing a great company from a good one was what they called having “Big Hairy Audacious Ideas.” This website is owned and operated by: MSL Media Limited

Co. Number: 05359182

© 2005 MSL Media Ltd. All rights reserved. E&OE